Grouting curtain drilling structure

A technology of grouting curtain and grouting hole, which is applied in earthwork drilling, drainage, safety devices, etc. It can solve the problems of grouting effect and grouting quality discount, increase drilling workload, and increase investment, so as to reduce drilling The effect of increasing the workload, increasing the diffusion radius of the slurry, and reducing the investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

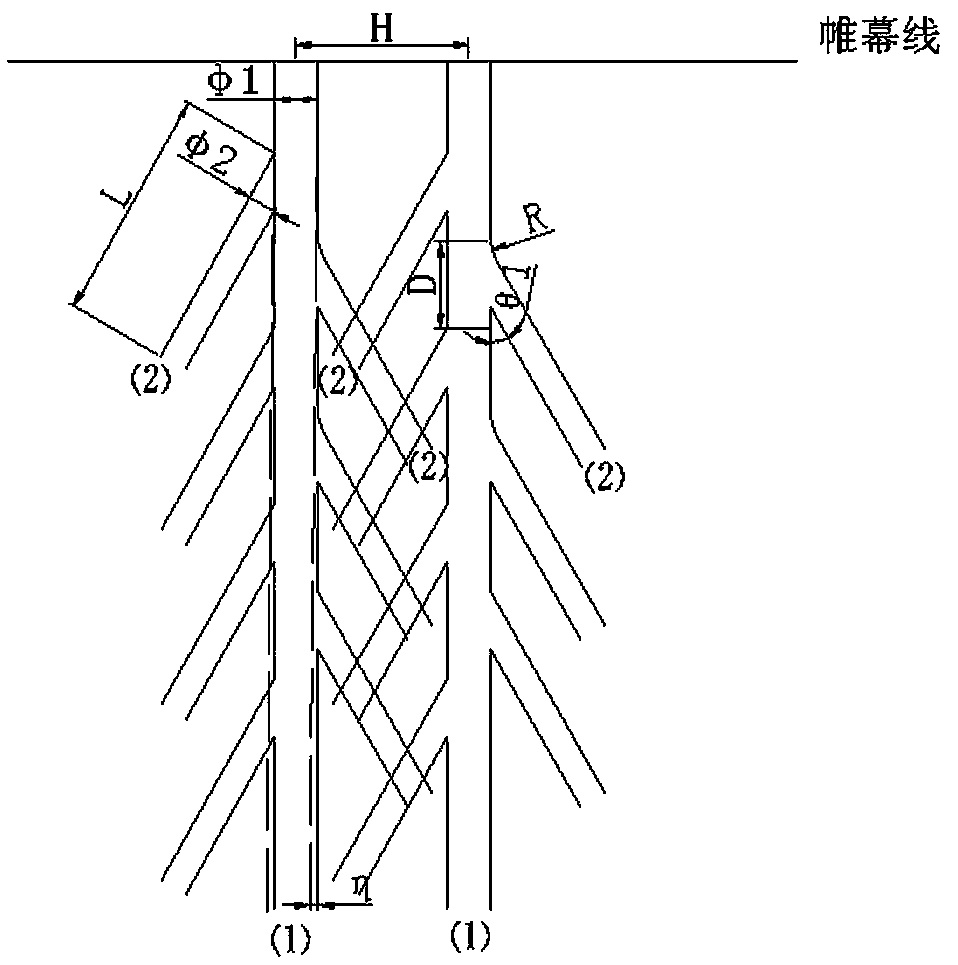

Embodiment 1

[0021] Embodiment 1: The grouting curtain drilling structure includes several straight grouting holes 1 arranged along the curtain line, and several straight grouting holes 1 are also provided around the height direction in the straight grouting holes 1. The grouting hole 1 is connected to the branch grouting hole 2 extending radially to the surroundings. After grouting, the direction along the curtain line can increase the high-angle water-conducting crack exposure rate or expose any angle of water-conducting crack. The direction of the branch grouting holes 2 is basically along the vertical plane of the curtain line or located in the vertical plane of the curtain line. The vertical surface of the curtain line is a plane. The branch grouting hole 2 is a downward sloping type. A row of branch grouting holes (2) located on the same side in the straight grouting hole 1 have the same inclination and spacing, forming a fishbone shape. Between two adjacent straight grouting holes...

Embodiment 2

[0023] In a certain iron ore mining area, the strata in the mining area are basically limestone strata, and the water permeability is extremely uneven. Firstly, straight grouting holes are constructed. The distance between the two straight grouting holes is 30m. The slope η was measured to be 4‰ and 3‰ respectively. After coring the straight grouting hole, it was found that the fracture angle was basically greater than 80°, which was a high-angle fracture. Through the direct grouting hole pressure water test, the average water permeability of about 0-200m is 3Lu, and the average water permeability of about 200-400m is 6.3Lu. In order to ensure the grouting effect, the distance D of branch grouting holes is set to 25m for 0-200m. 200-400m is 15m. Through the construction of the branch grouting hole, the final parameters are that the diameter of the branch grouting hole φ2 is 120mm, the radius of curvature R of the branch grouting hole is 3-4.5m, and the deflection angle θ1 of t...

Embodiment 3

[0027] In a roadway of a copper mine, the stratum in the mining area is dominated by granodiorite porphyry, with limestone in the middle, of which the limestone has a relatively high water permeability. First, direct grouting holes are constructed. The hole diameter φ1 is 155mm, and the deflection rate η of the straight grouting hole is measured to be 5‰ and 6.3‰ respectively. After coring the straight grouting hole, it is found that the cracks are irregular and chaotic. Through the direct grouting hole pressure water test, the average water permeability of granodiorite porphyry is 4.7 Lu, and the average water permeability of limestone is 10.4 Lu. In order to ensure the grouting effect, the distance D of branch grouting holes is set as granodiorite porphyry The lot is 20m and the limestone section is 15m. Through the construction of the branch grouting hole, the final parameters are that the diameter of the branch grouting hole φ2 is 120mm, the radius of curvature R of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com