A kind of ultraviolet fluid processor

A technology of ultraviolet rays and processors, applied in the direction of light water/sewage treatment, irradiation, etc., can solve the problems of short fluid irradiation process, unbalanced pressure, and different degrees of water pollution, and achieve little influence on fluid mixing dynamics, fluid mechanics Performance enhancements, effects of increased chance of fluid exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

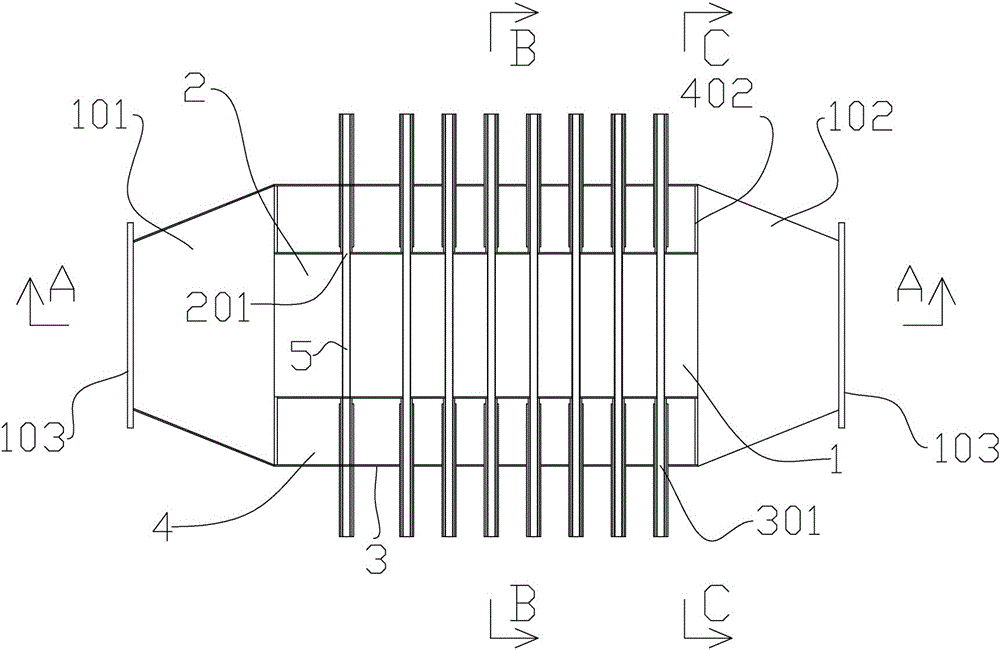

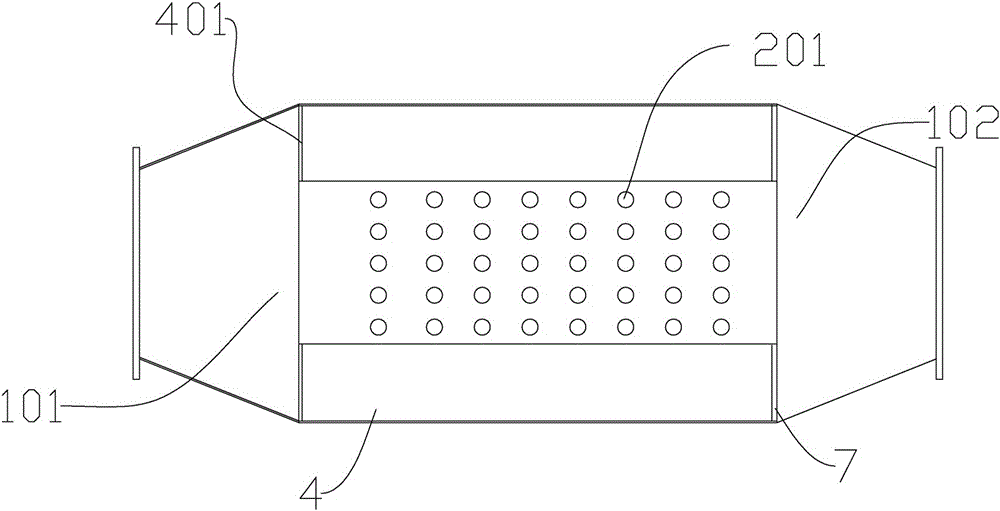

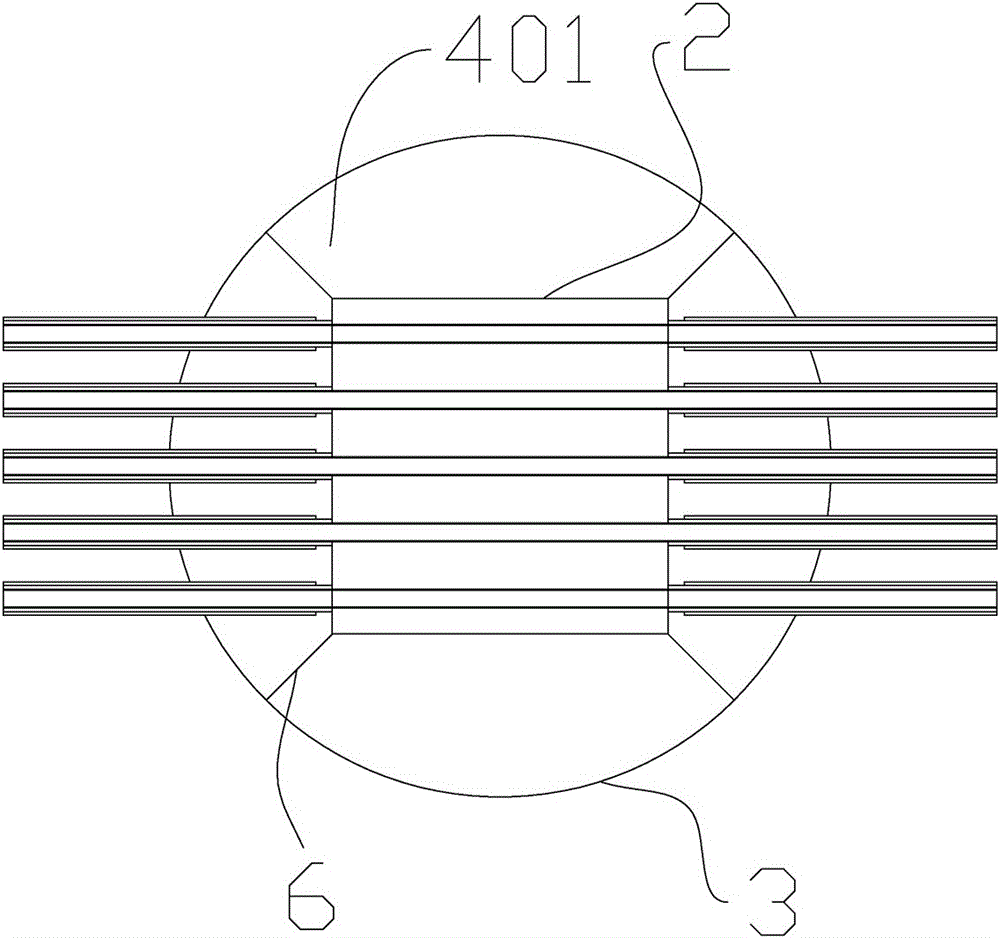

[0026] The following is attached Figure 1-4 The present invention is described in detail.

[0027] Such as Figure 1-4 As shown, an ultraviolet fluid processor includes a reactor body 1 and several low-pressure high-intensity ultraviolet lamp tubes and sleeves 5 with a length of 1554mm. The two ends of the reactor body 1 are respectively provided with a fluid inlet 101 and a fluid outlet 102 , the reactor body includes an inner cylinder 2 with openings at both ends having a square cross-section; the inner cylinder 2 is coaxially sleeved with an outer cylinder 3; the inner cylinder 2 and the outer cylinder 3 A continuous pressure balance chamber 4 is formed between them, the pressure balance chamber 4 is provided with an opening at the first end 401 close to the reactor fluid inlet 101, and is closed at the second end 402 close to the reactor fluid outlet 102; the inner cylinder 2 The support frame 6 is fixedly connected with the outer cylinder 3, and the support device 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com