Thermoplastic high-voltage cable insulation material and preparation method thereof

A high-voltage cable and insulating material technology, applied in plastic/resin/wax insulators, insulators, organic insulators, etc., can solve problems such as breakdown strength drop, space charge accumulation, agglomeration, etc., to suppress space charge injection and improve volume resistance. rate, the effect of enhancing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

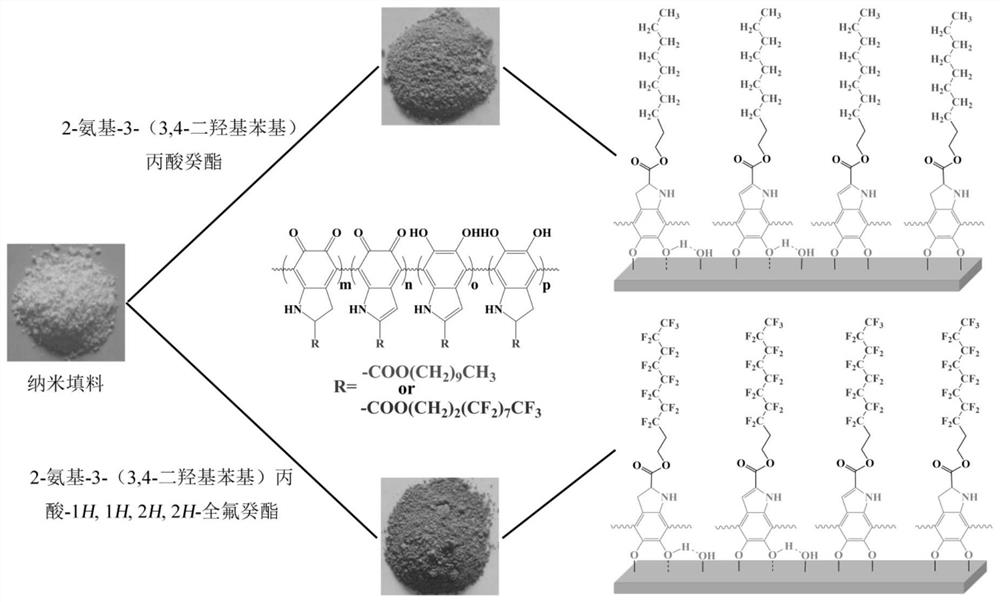

[0045]This embodiment relates to a thermoplastic high pressure cable insulating material, the insulating material from 90 parts of the polypropylene copolymer as a matrix, 6 parts of 2-amino-3- (3, 4 - Dihydroxyphenyl) propionic acid -1H, 1H, 2H, 2H-全fluorogen modified titanate nanoparticles are composed of fillers. Among them, 2-amino-3- (3,4-dihydroxyphenyl) propionic acid - 1H, 1H, 2H, 2H-perfluorogen modified titanate nanoparticles were prepared by the following steps:

[0046]A. Dopamine having a long chain structure: 1H, 1H, 2H, 2H-full fluorohyllol and L-3,4-dihydroxybenzlanine reaction, to give 2-amino-3- (3,4-dihydroxy) Phenyl) propionic acid - 1H, 1H, 2H, 2H-全fluorogene. This method of synthesis of dopamine having a long chain structure (Manolakis, i.Et Al., Macromol.rapid Commun.2014, 35, 71-76.).

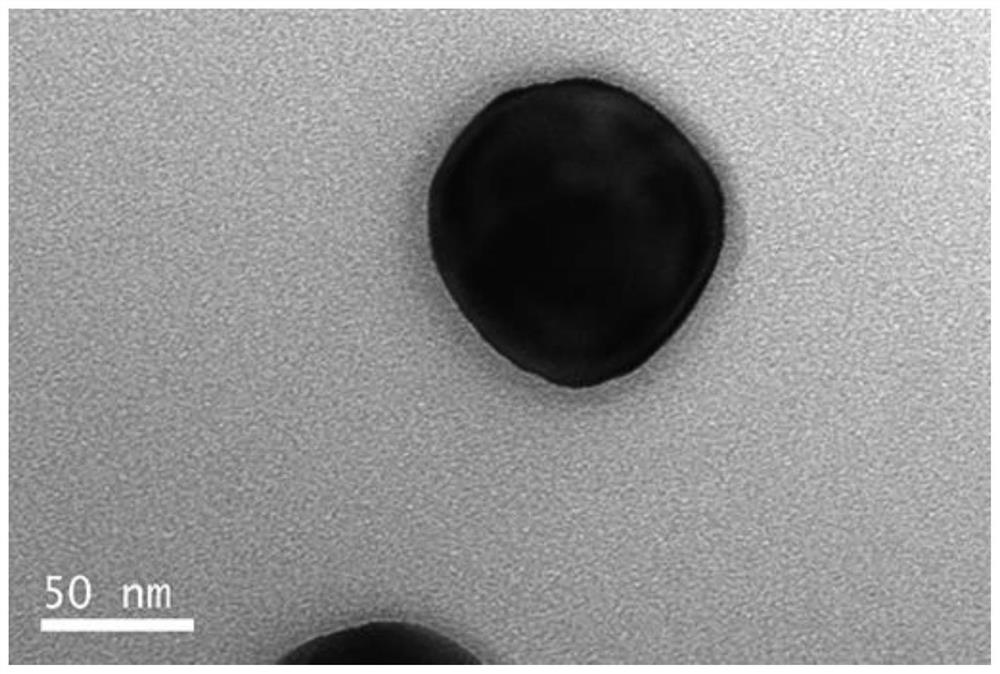

[0047]B. Dopamine-modified titanate nanoparticles of long chain structure: 2-amino-3- (3,4-dihydroxyphenyl) propionic acid - 1H, 1H, 2H, 2H-全 酯 解In isopropyl alcohol, the titanium d...

Embodiment 2

[0050]This embodiment relates to a thermoplastic high voltage cable insulating material, the insulating material consisting of 90 parts of polypropylene and 10 parts of the propylene-ethylene copolymer as a matrix, 5 parts of 2-amino-3- (3, 4- Dihydroxy phenyl) propionate modification of nanoparticles are composed as filler. Among them, 2-amino-3- (3,4-dihydroxyphenyl) propionate modified barium titanate nanoparticles were prepared by the following steps.

[0051]A. Dopamine having a long chain structure: 1-decanol is reacted with L-3,4-dihydroxybenzophenine to give 2-amino-3- (3,4-dihydroxyphenyl) propionate. This method of synthesis of dopamine having a long chain structure (Manolakis, i.Et Al., Macromol.rapid Commun.2014, 35, 71-76.).

[0052]C. Dopamine-modified titanate nanoparticles of the long chain structure: 2-amino-3- (3,4-dihydroxyphenyl) propionate is dissolved in isopropyl alcohol while strontium titanate nano The particles are dispersed in a hydrochloric acid buffer of three...

Embodiment 3

[0055]This embodiment relates to a thermoplastic high voltage cable insulating material, the insulating material from 100 parts of the like polypropylene as a substrate and 4 parts of 2-amino-3- (3,4-dihydroxyphenyl) propionic acid-1H , 1H, 2H, 2H-perfluorogen-modified magnesium oxide nanoparticles consist as filler. Among them, the preparation step of 2-amino-3- (3,4-dihydroxyphenyl) propionate modification of zitride-modified magnesium oxide nanoparticles is different, and the nanoparticles used are magnesium oxide.

[0056]This example also relates to a method of preparation of a thermoplastic high voltage cable insulating material, the method is 100 parts of the like polypropylene, 4 parts of a dopamine-modified magnesium oxide nanoparticle 1010 and 0.1 parts. The antioxidant 168 was added to the mesh, mixed at 200 ° C for 8 minutes to give a thermoplastic high voltage cable insulating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

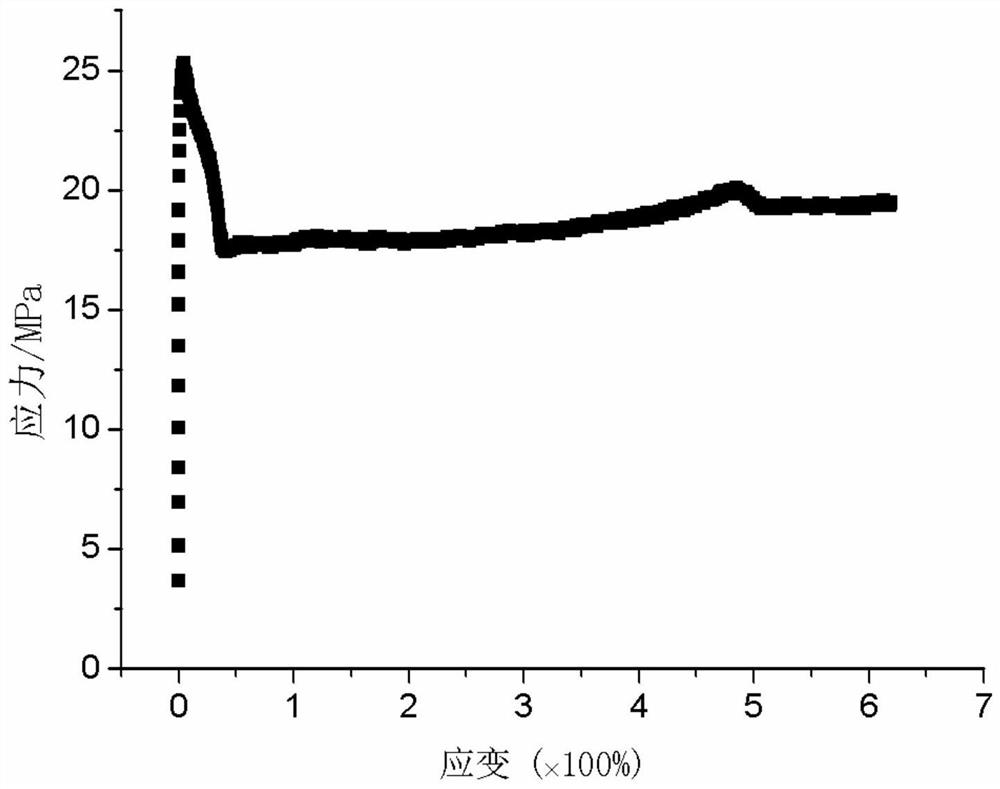

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com