Immobilized enzyme, immobilized enzyme carrier and preparation method of immobilized enzyme carrier

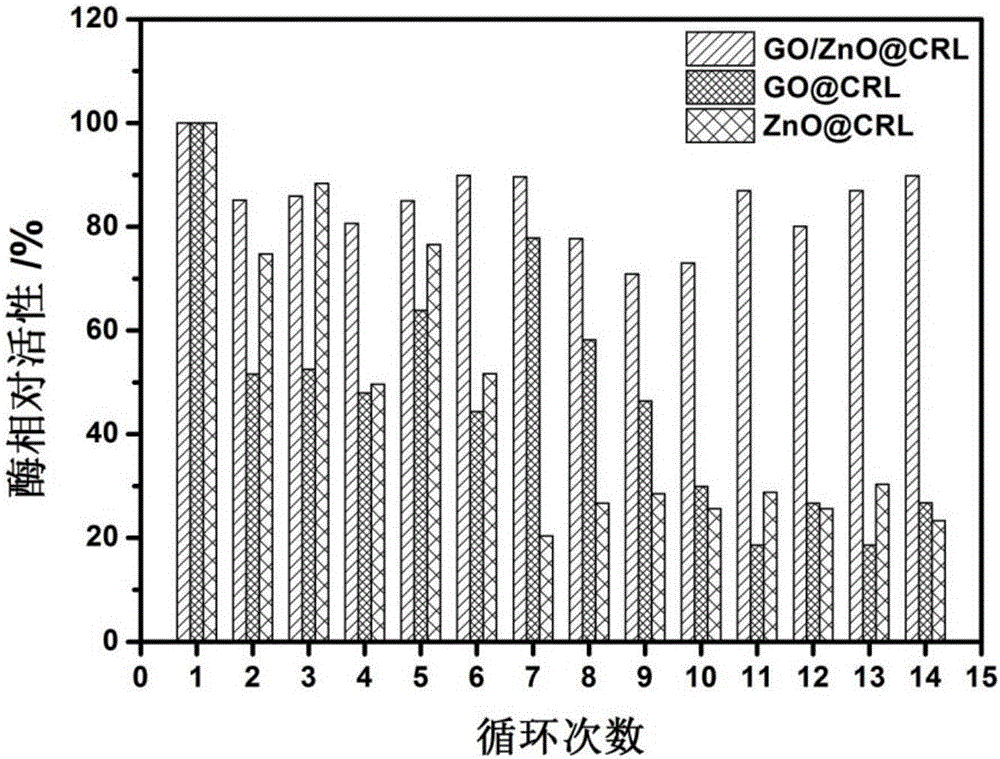

A technology of immobilizing enzyme carriers and fossils, which is applied in the field of enzyme immobilization, can solve the problems of unfavorable enzyme activity, operational stability, and poor immobilization of free enzymes, and achieve good reusable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention provides an immobilized enzyme carrier, and its specific preparation steps are as follows:

[0025] Take a certain amount of graphene oxide (replaced by GO below) and disperse it in deionized water, add an appropriate amount of zinc acetate, wherein the amount of zinc acetate added is to ensure that the mass percentage of zinc oxide in the formed immobilized enzyme carrier is 30%, and ultrasonic treatment for 1 hour; under the situation of stirring, add the mixed solution of NaOH and ethylene glycol, wherein the amount of NaOH is the same molar amount as zinc acetate, and the mass part of NaOH and the volume part of ethylene glycol are 1:10, specifically when When NaOH is 1g, ethylene glycol is 10ml; then continue to stir, add sodium citrate 10 times the mass of GO, stir for 1 hour, put the mixture in the reaction kettle, and react at 100°C for 12 hours; the reaction is over After that, wash and filter with ethanol and water, and dr...

Embodiment 2

[0032] Embodiment 2 of the present invention provides an immobilized enzyme carrier, and its specific preparation steps are as follows:

[0033] Weigh a certain amount of GO and disperse it in isopropanol, then add a certain amount of MnCl 2 4H 2 O, where MnCl was added 2 4H 2The amount of O is 30% to ensure that the mass percentage of manganese dioxide in the immobilized enzyme carrier that forms is 30%, ultrasonic treatment 1 hour; Add the ammoniacal solution of 10ml 2mol / L in the above-mentioned mixed solution again, continue ultrasonic stirring 30min; Then mix The solution was poured into the reaction kettle and heated at 120°C for 12 hours; after the reaction was completed, it was repeatedly washed with deionized water until neutral, then dried at 80°C, ground and burned to obtain GO / MnO 2 carrier material.

[0034] The method for preparing the immobilized enzyme in this example is basically the same as that in Example 1, so details will not be repeated here.

Embodiment 3

[0036] Embodiment 2 of the present invention provides an immobilized enzyme carrier, and its specific preparation steps are as follows:

[0037] Get 10g of surfactant sodium dodecylbenzenesulfonate and dissolve it in 100ml of deionized water, weigh 1g of GO to disperse it and ultrasonically form a uniform GO suspension; weigh 1.025g of Mg(NO 3 ) 2 ·6H 2 O, 0.375g Al(NO 3 ) 3 9H 2 O and urea are added in the there-necked flask that holds 200ml hydrogen peroxide solution, wherein the mass concentration of hydrogen peroxide solution is 20%, the solution in the three-necked flask is mechanically stirred for 15min and then added to the GO suspension, continuously stirred, and the stirred The solution was heated to 150° C. under the protection of nitrogen in an oil bath, kept stirring vigorously, and condensed and refluxed at 150° C. for 8 hours. After the reaction was completed, the reaction product was filtered and washed 4 times with ultrapure water. The GO / LDH carrier mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com