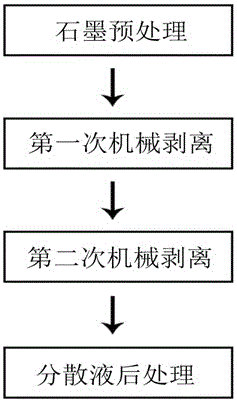

Method for preparing graphene micro-sheet dispersion on grade by mechanical stripping

A graphene microchip and mechanical exfoliation technology, which is applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor uniformity of graphene particle size, low graphene exfoliation efficiency, poor product repetition rate, etc., to achieve Improved stripping efficiency, high product quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 100g of graphite and 100g of ammonium persulfate, pour them into 500ml of deionized water, stir at 25-100°C for 3h, then add 200g of weighed sodium carbonate into the graphite mixture, and lower the temperature to 25- 80℃, soak for 5h;

[0035] will step The graphite mixed solution treated in the medium is suction-filtered, and the graphite is rinsed with a small amount of deionized water for 3-5 times, and then the filtered graphite is re-mixed with 500ml of deionized water to prepare a graphite mixed solution;

[0036] will step The pretreated graphite mixed solution in the mixture is poured into a mechanical stirring device, and the rotating speed of the mechanical stirrer is set to 20rpm to carry out preliminary exfoliation of graphite, and mechanically exfoliate at this rotating speed for 0.5h to obtain a larger primary graphene dispersion with a particle size ;

[0037] To step Add polyethylene glycol surfactant 60g in the primary graphene ...

Embodiment 2

[0041] Weigh 100g of graphite and 100g of ammonium persulfate, pour them into 500ml of deionized water, stir at 25-100°C for 3h, then add 200g of weighed sodium carbonate into the graphite mixture, and lower the temperature to 25- 80℃, soak for 5h;

[0042] will step The graphite mixed solution treated in the medium is suction-filtered, and the graphite is rinsed with a small amount of deionized water for 3-5 times, and then the filtered graphite is re-mixed with 500ml of deionized water to prepare a graphite mixed solution;

[0043] will step The pretreated graphite mixed solution in the mixture is poured into a mechanical stirring device, and the rotating speed of the mechanical stirrer is set to 50rpm to carry out preliminary exfoliation of graphite, and mechanically exfoliate at this rotating speed for 0.5h to obtain a larger primary graphene dispersion with a particle size ;

[0044] To step Add polyethylene glycol surfactant 60g in the primary graphene...

Embodiment 3

[0048] Weigh 100g of graphite and 100g of ammonium persulfate, pour them into 500ml of deionized water, stir at 25-100°C for 3h, then add 200g of weighed sodium carbonate into the graphite mixture, and lower the temperature to 25- 80℃, soak for 5h;

[0049] will step The graphite mixed solution treated in the medium is suction-filtered, and the graphite is rinsed with a small amount of deionized water for 3-5 times, and then the filtered graphite is re-mixed with 500ml of deionized water to prepare a graphite mixed solution;

[0050] will step The pretreated graphite mixed solution in the mixture is poured into a mechanical stirring device, and the rotating speed of the mechanical stirrer is set to 50rpm to carry out preliminary exfoliation of graphite, and mechanical exfoliation at this rotating speed for 1.5h, to obtain a primary graphene dispersion with a larger particle size ;

[0051] To step Add polyethylene glycol surfactant 60g in the primary graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com