Punch used for stamping die

A technology of stamping dies and punches, applied in the field of molds, can solve the problems of poor wear resistance of punches, achieve good cooling, good lubrication, and improve processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

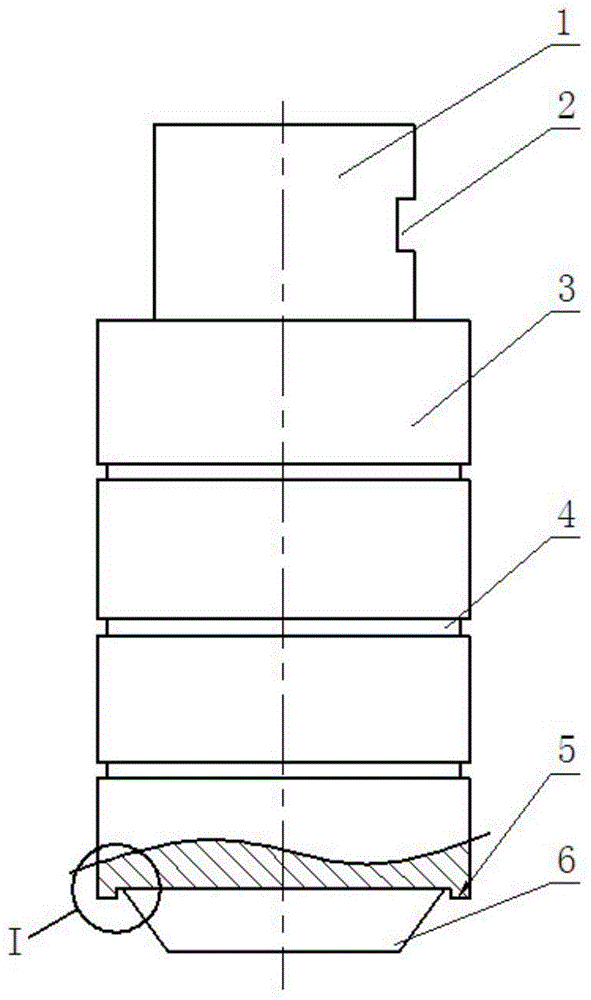

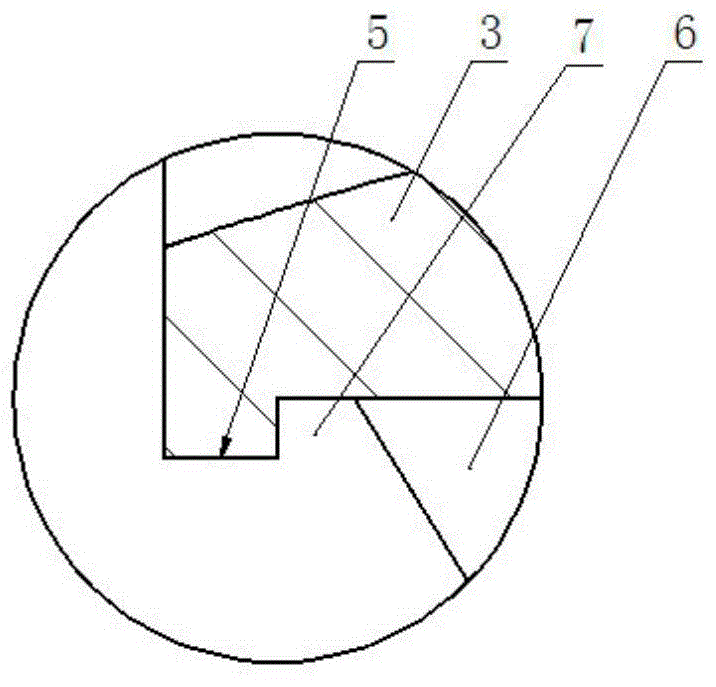

[0020] A punch used in stamping dies such as figure 1 As shown, the upper part of the body 3 of the punch is coaxially formed with a handle section 1, and the lower part of the body is coaxially formed with a transition section 6. The transition section is a frustum-shaped structure, which improves the positioning accuracy of the punch when punching. ; The outer edge of the lower end surface of the body is integrally formed with an annular boss 5 downwards, such as figure 2 As shown, an annular groove 7 is formed between the annular boss and the transition section, and coolant can be stored in the annular groove to avoid cracking or surface strain of the punch due to thermal fatigue and prolong the service life.

[0021] In this embodiment, the outer edge of the body is uniformly spaced and coaxially formed with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com