Biomimetic mineralized adhesive film prepared from polymer film forming material-loaded ACP and in-vitro induction remineralization method

A film-forming material and biomimetic mineralization technology, applied in dental prostheses, pharmaceutical formulas, dental preparations, etc., can solve problems such as uncertain actual effects, and achieve the effects of wide application, easy use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] Embodiment 1: The preparation of HPMC-loaded ACP biomimetic mineralization film is as follows: add HPMC powder to 70% ethanol aqueous solution at a ratio of 1:6, and after it is completely swollen into a glue, then add 800 μg / ml PAA-stabilized ACP at a ratio of 1:4 Add to HPMC sol and stir well. After the air bubbles in the sol are removed by ultrasonic or vacuum, apply a thin layer evenly on the flat plate, put it in an oven to dry, cool, and form a film, and cut it into films of different sizes.

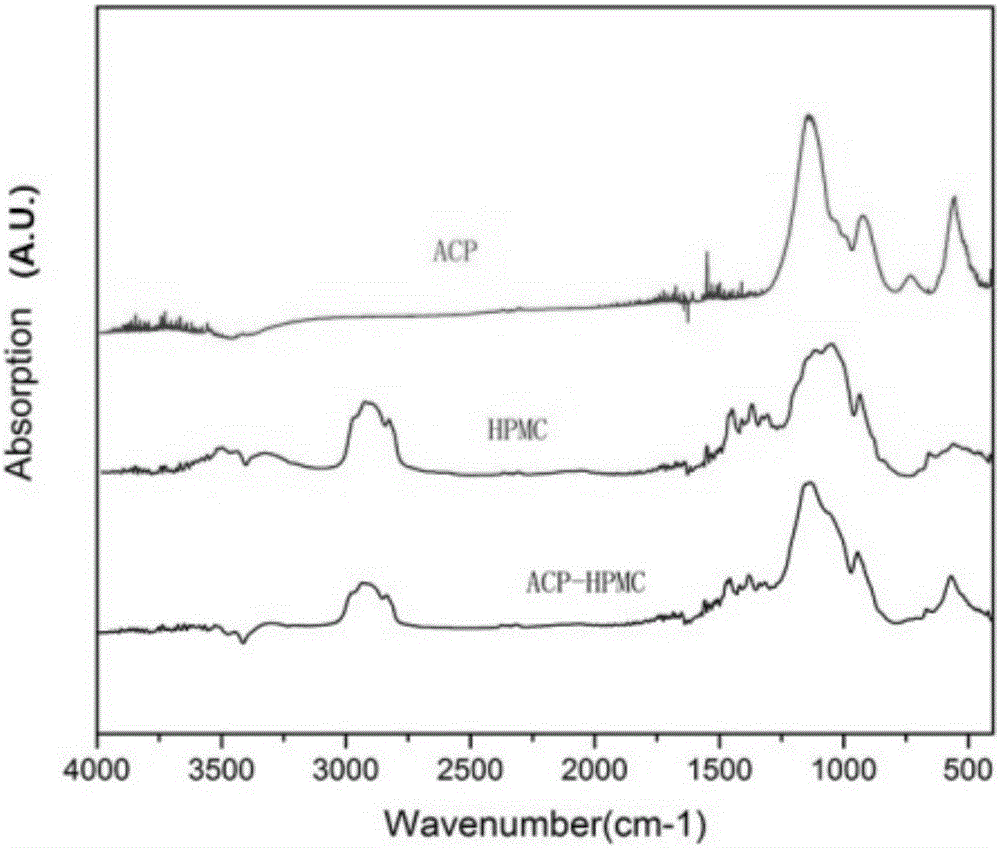

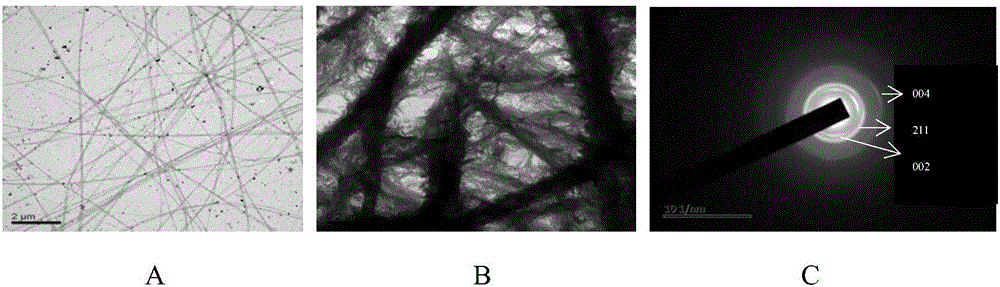

[0048] Before applying the HPMC-loaded ACP film, the phase transition of ACP in the mineralized film was characterized by Fourier transform infrared spectroscopy (FTIR). The result is as figure 1 As shown, in the infrared spectrum of ACP, at 534cm -1 and 1100cm -1 The absorption peak at PO4 3- cause, of which 534cm -1 The absorption peak at the position does not split, indicating that the measured sample is not crystallized and is an amorphous phase, indicating that ACP...

Embodiment approach 2

[0051] Embodiment 2: Preparation of chitosan-loaded ACP biomimetic mineralization film: add chitosan powder to pure aqueous solution at a ratio of 1:5, and after it is completely swollen into a glue, add 4mg / ml PAsp stabilized ACP at a ratio of 1:5 1 Add to the sol and mix well. After the air bubbles in the sol are removed by ultrasonic or vacuum, apply a thin layer evenly on the flat plate, put it in an oven to dry, cool, and form a film, and cut it into films of different sizes. Fourier transform infrared spectroscopy (FTIR) characterization is the same as scheme 1.

[0052] Preparation of demineralized tooth enamel: Select a freshly extracted human third molar without caries, defects, and cracks for the experiment, store it in 0.5% chloramine solution, and use it within one month. Under running water, 70 pieces of enamel slices with a size of about 5mm*5mm*1mm were prepared on the buccal and lingual sides parallel to the long axis of the crown with an Isomet low-speed micr...

Embodiment approach 3

[0054] Embodiment 3: Preparation of KGM-loaded ACP biomimetic mineralization film: add KGM powder to absolute ethanol at a ratio of 1:9, and after it is completely swollen into a glue, add polyelectrolyte-stabilized ACP and L-glutamic acid to simulate NCPs , the mass ratio of L-glutamic acid to polyelectrolyte-stabilized ACP is 1:3 and fully stirred and mixed. After the air bubbles in the sol are removed by ultrasonic or vacuum, apply a thin layer evenly on the flat plate, put it in an oven to dry, cool, and form a film, and cut it into films of different sizes.

[0055] Preparation of demineralized dentin: Select a freshly extracted human third molar without caries, defects, and cracks for the experiment, store it in 0.5% chloramine solution, and use it within one month. Under running water, 70 dentin slices with a size of about 3*2*1mm were prepared in the middle of the crown perpendicular to the long axis of the crown with an Isomet low-speed microtome. 37% phosphoric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com