Liquefied gas treatment system

A processing system and technology for liquefied gas, applied in liquefaction, gas processing/storage effect, fluid processing, etc., can solve problems such as different states, and achieve the effects of preventing accumulation, improving reliquefaction efficiency, and improving driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

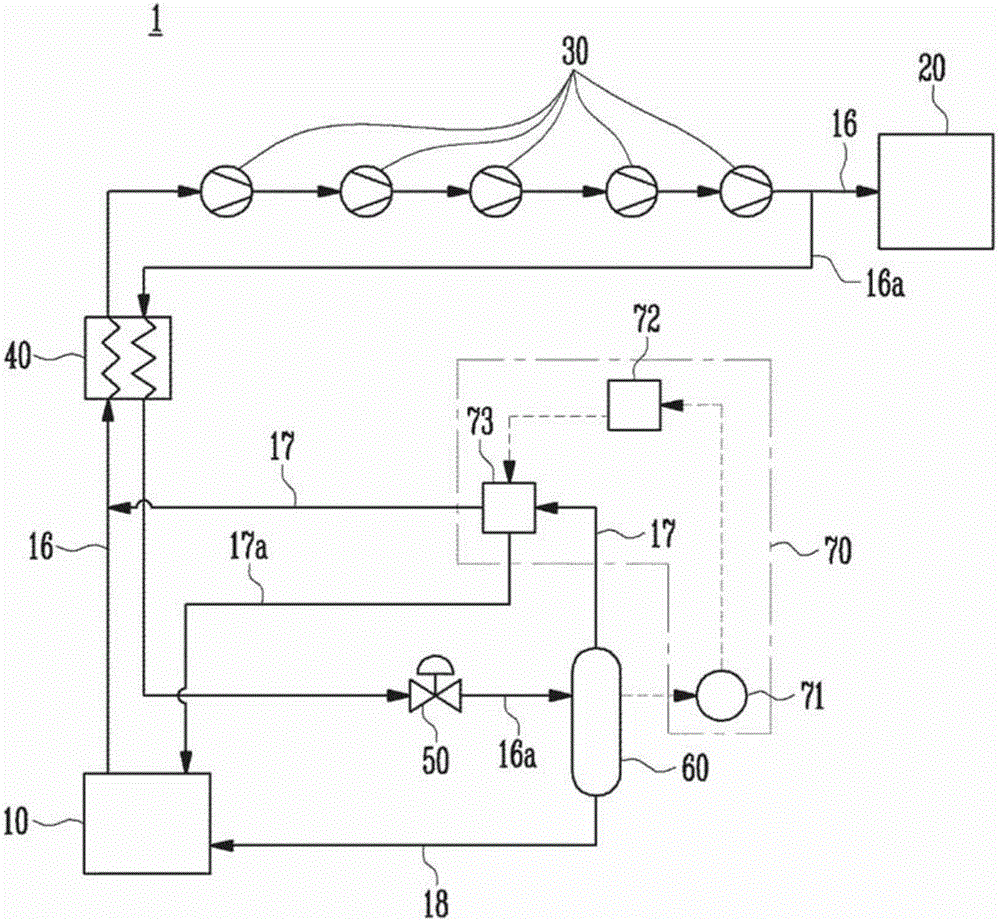

Method used

Image

Examples

Embodiment approach

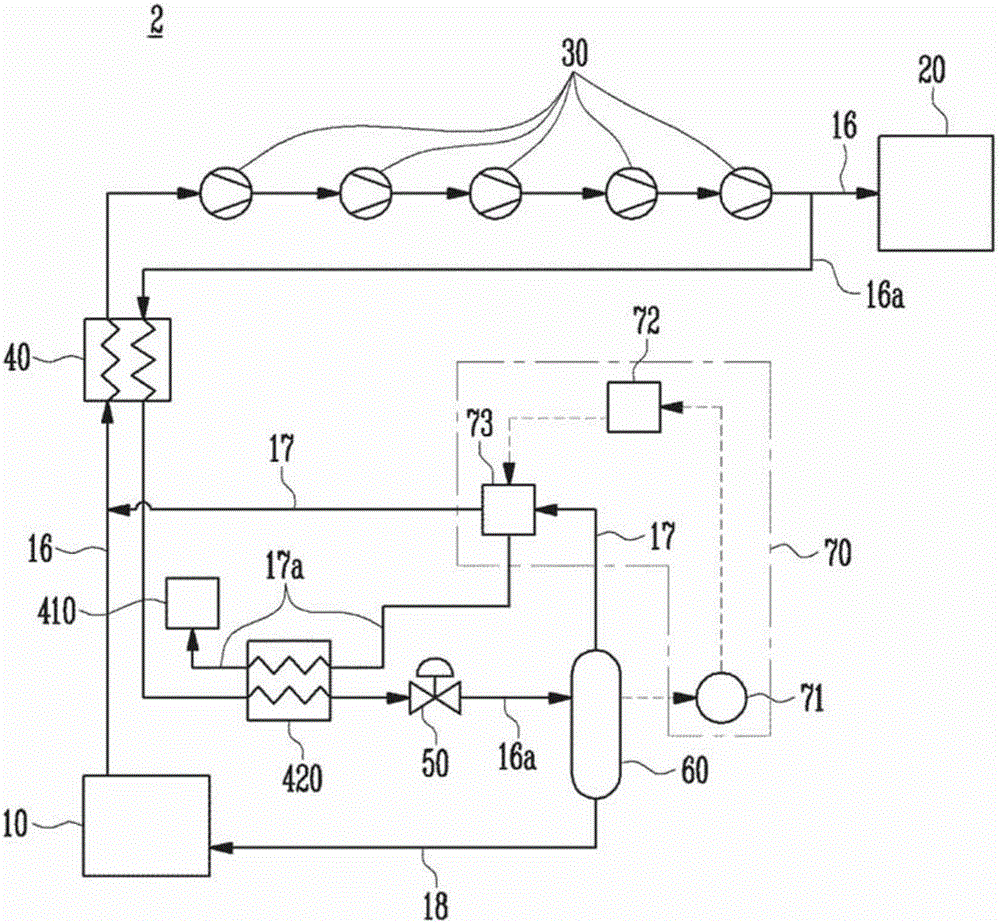

[0100] Such as image 3 As shown, the liquefied gas treatment system 2 of the second embodiment of the present invention includes a liquefied gas storage tank 10, a demand source 20, a boil-off gas compressor 30, a boil-off gas heat exchanger 40, a boil-off gas liquefier 50, a steam-liquid Separator 60 , nitrogen control unit 70 , consumption source 410 , and flash gas heat exchanger 420 . Compared with the first embodiment of the present invention, the second embodiment of the present invention has a different configuration of the consumption source 410 and the flash gas heat exchanger 420, and the connection relationship of the steam processing pipeline 17a related to this configuration is also different. For the sake of convenience, components identical to or corresponding to those in the first embodiment of the present invention are denoted by similar symbols, and repeated description thereof will be omitted.

[0101] The consumption source 410 may be a gas combustion un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com