Fuel gas supply system

A gas supply system and gas technology, applied in the direction of charging system, oil supply device, combustion engine, etc., can solve the problems of reduced reliquefaction efficiency of evaporated gas, influence of application and treatment of evaporated gas, and reduction of gas calorific value, etc., to achieve improved Reliquefaction efficiency, simple structure, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following embodiments are provided in order to fully convey the technical idea of the present invention to those having general knowledge in the technical field to which the present invention pertains. The present invention is not limited to the examples provided below, and it can also be embodied in other forms. In the drawings, illustrations of parts irrelevant to the description are omitted in order to clarify the present invention, and components are shown slightly exaggerated to facilitate understanding.

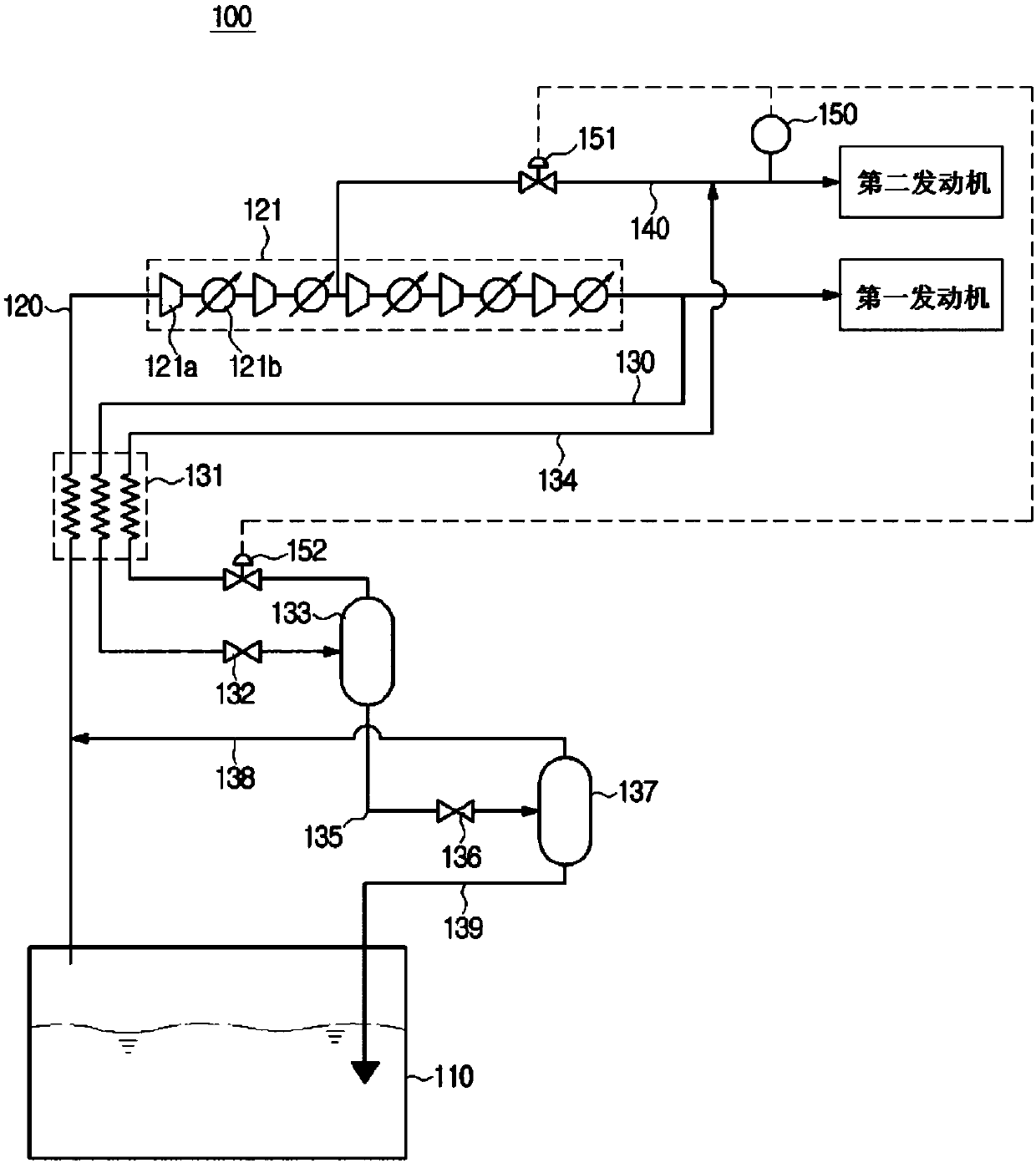

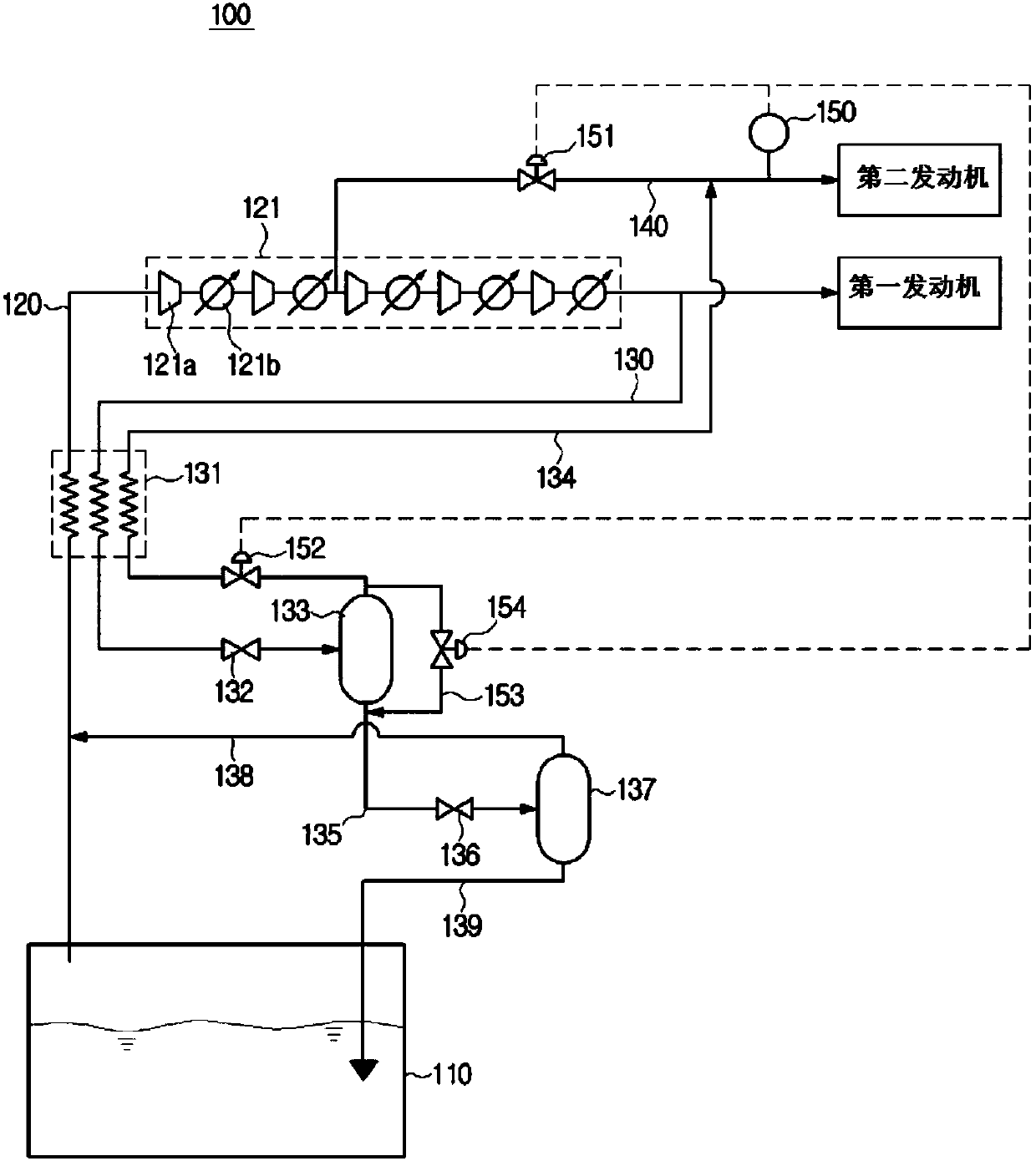

[0030] figure 1 A gas supply system 100 related to an embodiment of the present invention is shown.

[0031] refer to figure 1 , The gas supply system 100 related to the embodiment of the present invention includes: a storage tank 110; a compression part 121 for pressurizing the boil-off gas in the storage tank 110, and the boil-off gas pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com