Ship including engine and method for increasing reliquefaction efficiency

A technology for engines and ships, applied in the direction of container discharge methods, ship propulsion, container filling methods, etc., can solve problems such as limited and external heat blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, embodiments of the present invention will be explained in detail with reference to the accompanying drawings. A ship including an engine according to the present invention can be applied to various marine systems and land systems. It should be understood that the following examples can be modified in various ways and do not limit the scope of the present invention.

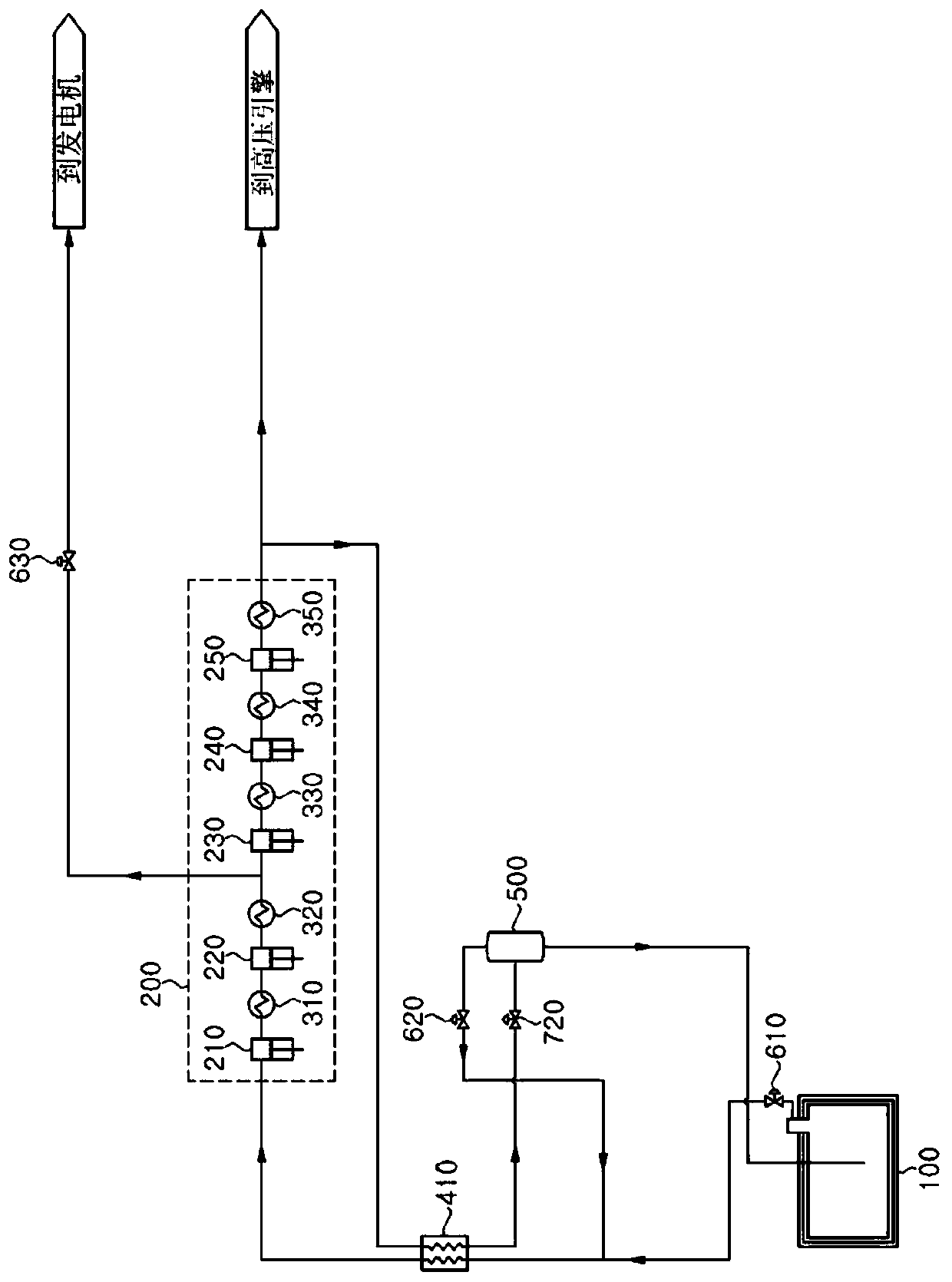

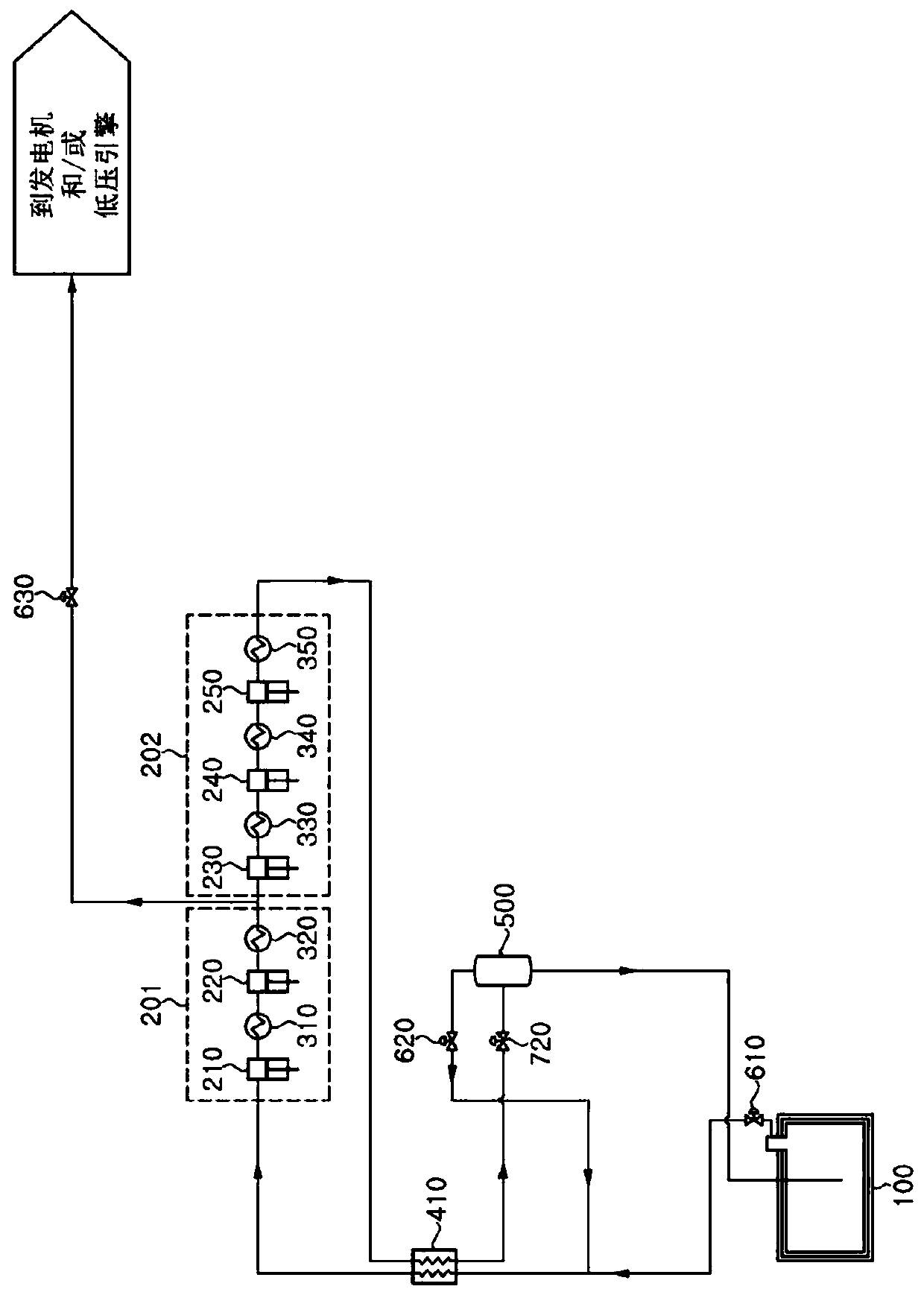

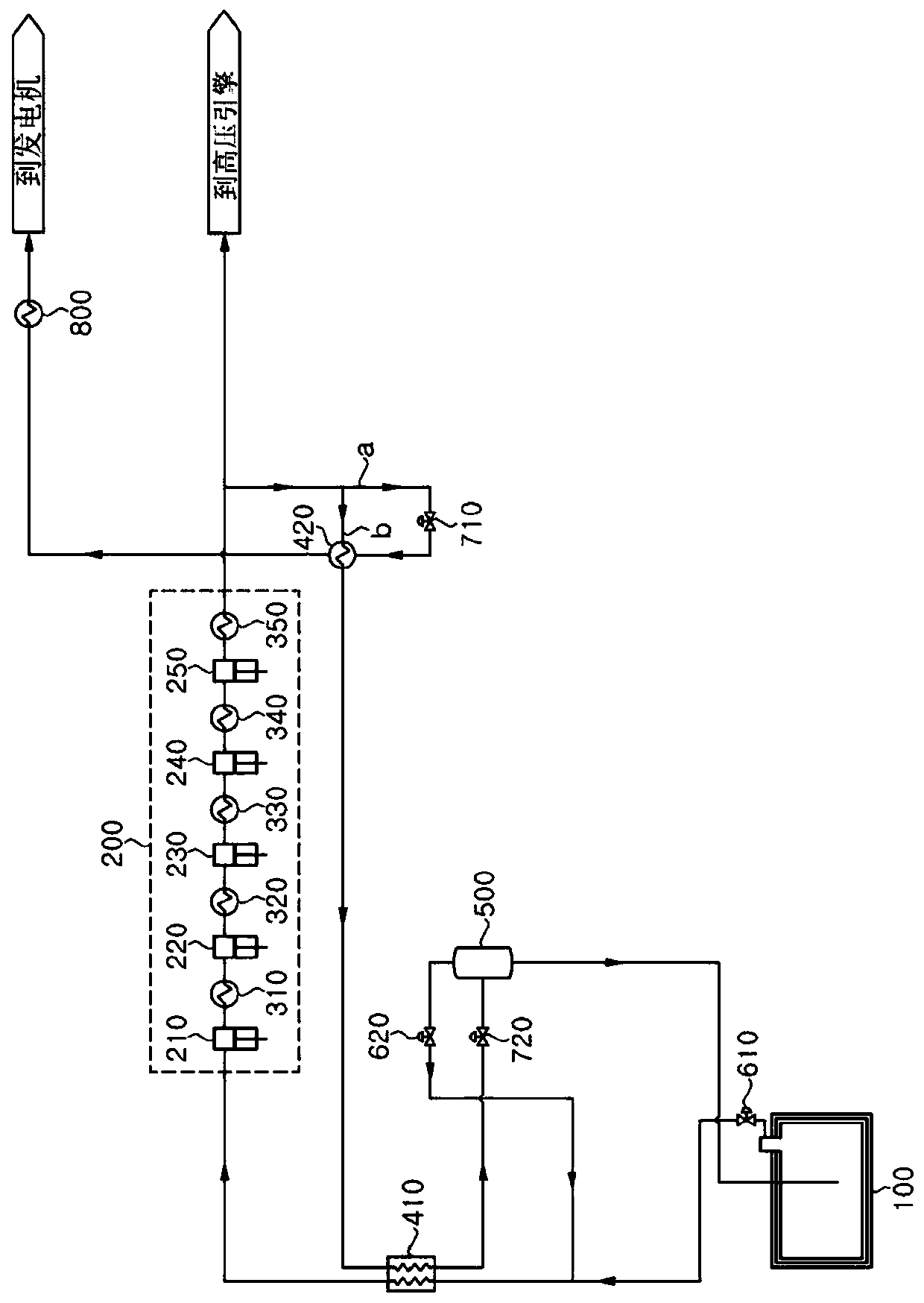

[0056] image 3 is a schematic diagram of a partial reliquefaction system applied to a vessel including a high pressure engine according to one embodiment of the present invention.

[0057] In this embodiment, the boil-off gas discharged from the storage tank 100 will be generally referred to as boil-off gas and means not only boil-off gas in gaseous or vapor phase, but also in gas phase, gas-liquid mixed phase, liquid phase, and supercritical Evaporated gas of the fluid phase (supercritical fluid phase).

[0058] refer to image 3 , the ship according to this embodiment includes: a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com