Aluminium hydroxide drying system and drying method thereof

A technology of aluminum hydroxide and drying system, applied in drying, drying machine, drying solid materials, etc., can solve the problems of take away, complicated electrical system and automatic control system, energy loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

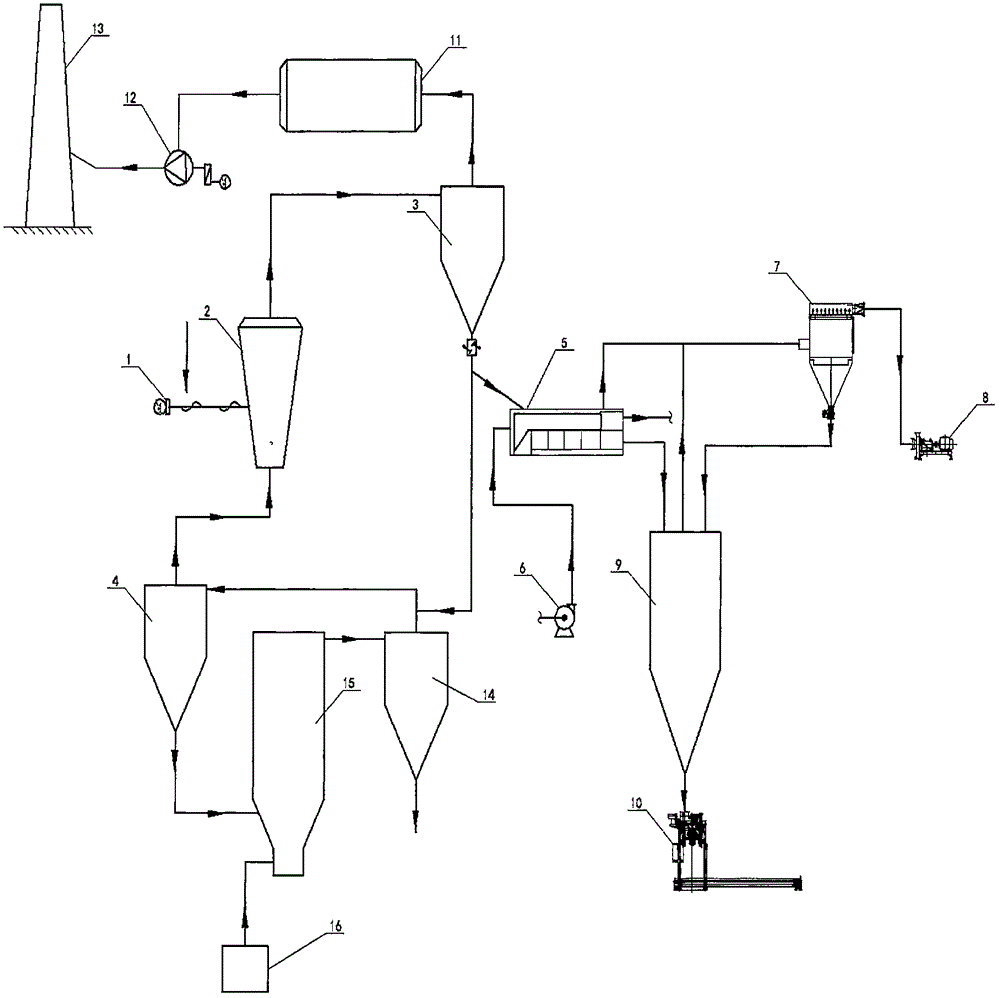

[0025] A drying system for aluminum hydroxide, comprising screw feeder 1, Venturi dryer 2, primary preheating cyclone separator 3, secondary preheating cyclone separator 4, fluidized cooler 5, bag collection Dust collector 7, dust collection fan 8, finished product storage bin 9, electric dust collector 11, induced draft fan 12;

[0026] Among them, the screw feeder 1 is connected with the Venturi dryer 2 and feeds it; the flue gas drawn from the top of the secondary preheating cyclone separator 4 is connected to the lower part of the Venturi dryer 2 with a pipeline, and is dried by the Venturi The top of the device 2 is connected to the top of the first-stage preheating cyclone separator 3 through a pipeline; another branch of the lower outlet pipeline of the first-stage preheating cyclone separator 3 is connected to a fluidized cooler 5, and the fluidized The lower outlet of the cooler 5 is piped into the finished product storage bin 9; the first-stage preheating cyclone sep...

Embodiment 2

[0029] A method for drying aluminum hydroxide using a drying system of the present invention, comprising the following steps:

[0030] The wet aluminum hydroxide material is supplied to the Venturi dryer 2 through the screw feeder 1; the flue gas at about 300-400 °C drawn from the secondary preheating cyclone separator 4 passes through the Venturi dryer 2, and the flue gas The gas is mixed with the wet aluminum hydroxide material to transfer heat, so that the wet aluminum hydroxide material can be heated rapidly to 120-180 ° C, and the attached water in the wet aluminum hydroxide material is removed, and the venturi dryer 2 is transported to the first-stage preheating cyclone separation Carry out gas-solid separation in device 3;

[0031] The power of the gas flow in the primary preheating cyclone separator 3 comes from the induced draft fan 12, which makes it work under negative pressure. 12 is discharged through the chimney 13;

[0032] The dried aluminum hydroxide is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com