Refrigerant mass and flow measuring method and device and measuring instrument

A mass flow and measurement method technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of refrigeration system unit damage, destruction of refrigeration system units, unsuitable unit field measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

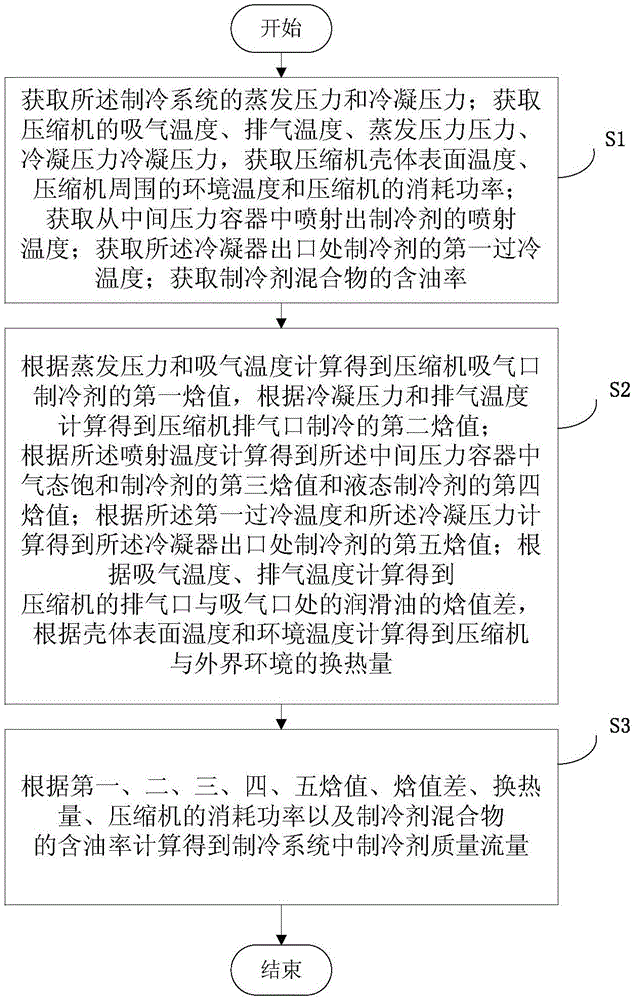

[0054] This embodiment provides a method for measuring refrigerant mass flow, which can be used in a refrigeration system. The refrigeration system includes: an evaporator, a compressor, a condenser, and an intermediate pressure vessel (the intermediate pressure vessel may be a flasher or a intercooler) and throttle valve, the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor is connected to the inlet of the condenser, such as figure 1 As shown, the method is as follows:

[0055] S1: Obtain the evaporation pressure and condensation pressure of the refrigeration system; obtain the suction temperature and discharge temperature of the compressor, obtain the surface temperature of the compressor shell, the ambient temperature around the compressor, and the power consumption of the compressor; The injection temperature of the refrigerant injected in the pressure vessel; the first subcooling temperature of the refrigerant at the o...

Embodiment 2

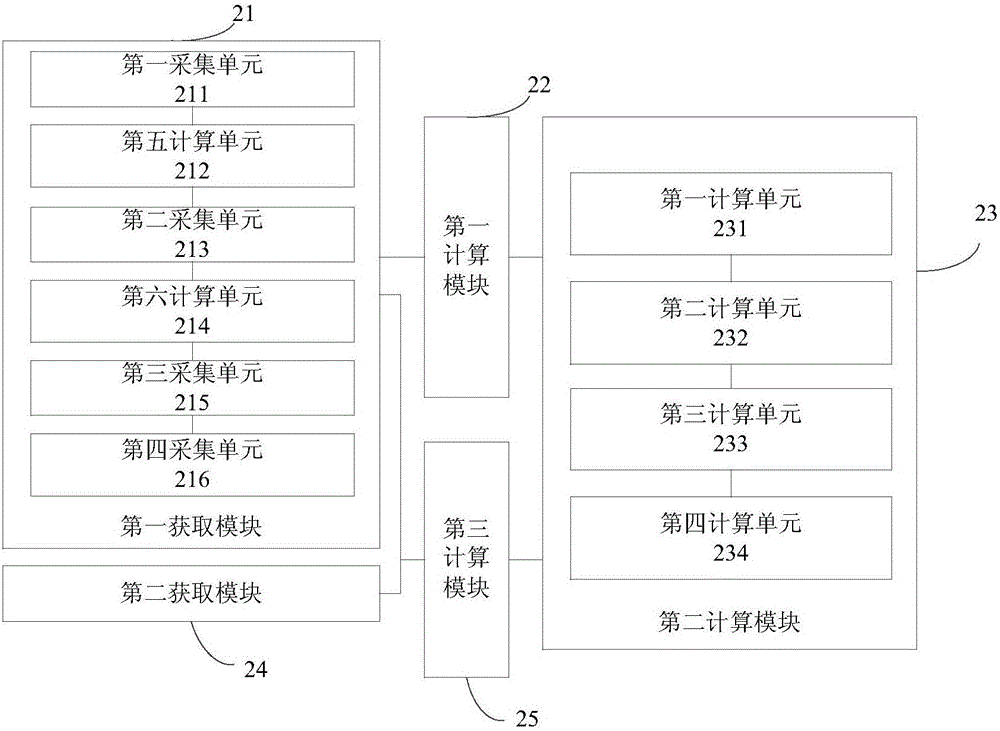

[0073] This embodiment provides a refrigerant mass flow measurement device, which can be used in a refrigeration system. The refrigeration system includes: an evaporator, a compressor, a condenser, and an intermediate pressure vessel (the intermediate pressure vessel may be a flasher or a intercooler) and throttle valve, the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor is connected to the inlet of the condenser, such as figure 2 As shown, the device includes:

[0074] The first obtaining module 21 is used to obtain the evaporating pressure and condensing pressure of the refrigeration system; obtain the suction temperature and discharge temperature of the compressor, obtain the surface temperature of the compressor shell, the ambient temperature around the compressor and the temperature of the compressor Power consumption; obtaining the injection temperature of the refrigerant injected from the intermediate pressure ves...

Embodiment 3

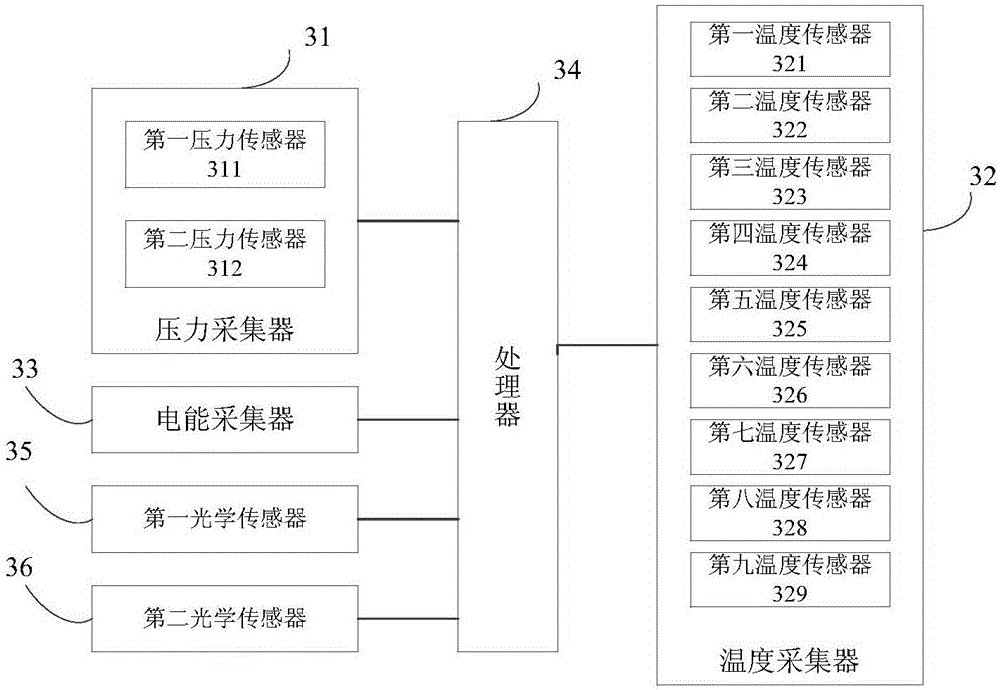

[0091] This embodiment provides a refrigerant mass flow meter, which can be used in refrigeration systems, such as image 3 As shown, the device includes: a processor 34 and a pressure collector 31 connected to the processor 34, a temperature collector 32 and an electric energy collector 33. In practical applications, by combining the pressure collector 31, the temperature collector 32 and the electric energy collector Devices 33 are respectively deployed in the refrigeration system to collect the state parameters of the refrigeration system in real time, such as Figure 4 As shown, the refrigeration system includes: an evaporator 41, a compressor 42, a condenser 43, a flasher 44 (that is, the flasher 44 here is an intermediate pressure vessel) and a throttle valve 45, and the outlet of the evaporator 41 is connected to the compressor The inlet of the machine 42, the outlet of the compressor 42 is connected to the inlet of the condenser 43, as follows Figure 4 The shown sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com