Steel brake drum

A brake drum, carbon steel technology, applied in the direction of brake drum, slack adjuster, gear shifting mechanism, etc., can solve the problems of inability to achieve rapid cooling, poor toughness, early failure of the brake drum, etc. Improve service life and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

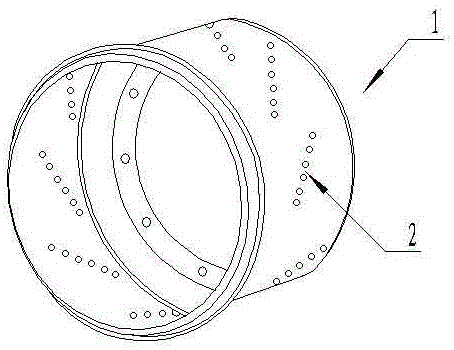

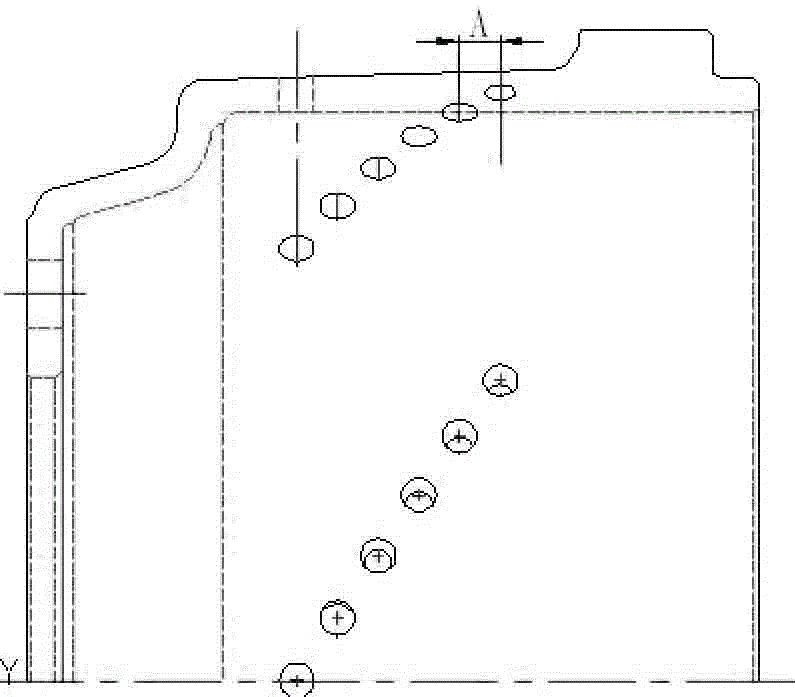

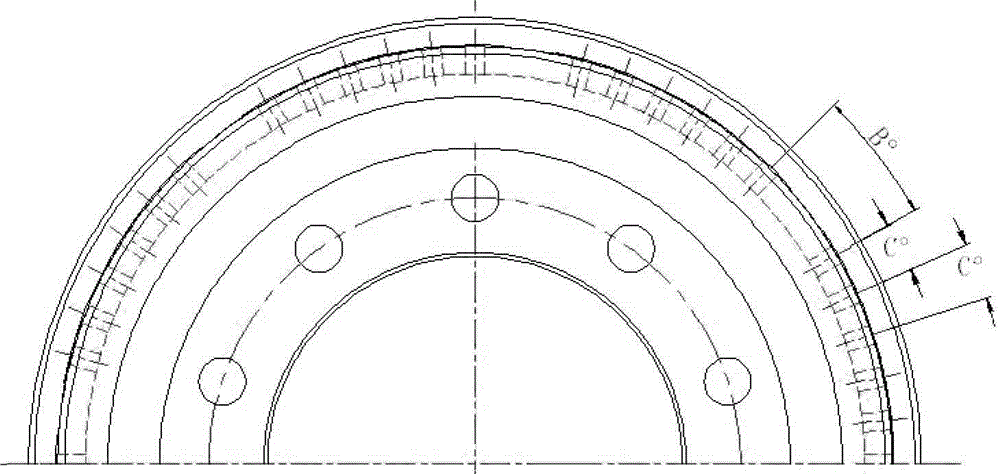

[0019] A kind of steel brake drum, it comprises brake drum body 1, the brake surface of described brake drum body 1 is evenly provided with 6 groups of ventilating heat dissipation holes 2 arranged uniformly, each group of ventilating heat dissipation holes 2 The number is 4, and the center-to-center distance angle B of the adjacent two adjacent holes in two groups of ventilation and cooling holes 2 is 12°; and the adjacent two holes in each group of ventilation and cooling holes 2 are along the braking The axial spacing A of the drum body 1 is 12 mm, and the spacing angle C between two adjacent holes in each group of ventilation and cooling holes 2 perpendicular to the axial direction of the brake drum body 1 is 4°.

[0020] The holes in the ventilation and heat dissipation holes 2 in the present invention are circular, and the diameter of the holes is φ6mm.

[0021] The brake drum body 1 of the present invention is made of cast steel, and the cast steel is made of low-carbon...

Embodiment 2

[0024] A steel brake drum, which includes a brake drum body 1, 8 groups of ventilation and cooling holes 2 arranged uniformly on the braking surface of the brake drum body 1, each group of ventilation and cooling holes 2 The number is 8, and the center-to-center distance angle B of the adjacent two holes in the adjacent two groups of ventilation and heat dissipation holes 2 is 18°; and the adjacent two holes in each group of ventilation and heat dissipation holes 2 are along the The axial spacing A of the drum body 1 is 20 mm, and the spacing angle C between two adjacent holes in each group of ventilation and cooling holes 2 perpendicular to the axial direction of the brake drum body 1 is 10°.

[0025] The holes in the ventilation and heat dissipation holes 2 are oval. The brake drum body 1 is made of cast steel, and the cast steel is made of high carbon steel, wherein the carbon content in the high carbon steel is 0.6-0.8% by weight. The braking surface of the brake drum bod...

Embodiment 3

[0027] A steel brake drum, which includes a brake drum body 1, 8 groups of ventilation and cooling holes 2 arranged uniformly on the braking surface of the brake drum body 1, each group of ventilation and cooling holes 2 The number is 8, and the center-to-center distance angle B of the adjacent two holes in the adjacent two groups of ventilation and heat dissipation holes 2 is 18°; and the adjacent two holes in each group of ventilation and heat dissipation holes 2 are along the The axial spacing A of the drum body 1 is 20 mm, and the spacing angle C between two adjacent holes in each group of ventilation and cooling holes 2 perpendicular to the axial direction of the brake drum body 1 is 10°. The hole in the ventilation and heat dissipation hole 2 is circular, and the diameter of the hole is φ15mm when the hole is circular.

[0028] The brake drum body 1 is made of cast steel, and the cast steel is made of alloy steel, wherein the carbon content in the alloy steel is 0.2-0.8%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com