Telescopic single mechanical arm duct piece splicing machine for rectangular shield

A technology of segment assembly machine and single robot arm, which is applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problem of reducing segment assembly speed and construction rate, it is difficult to accurately control the moving distance of shield tunnel segments, and the influence of tube The quality of piece assembly and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

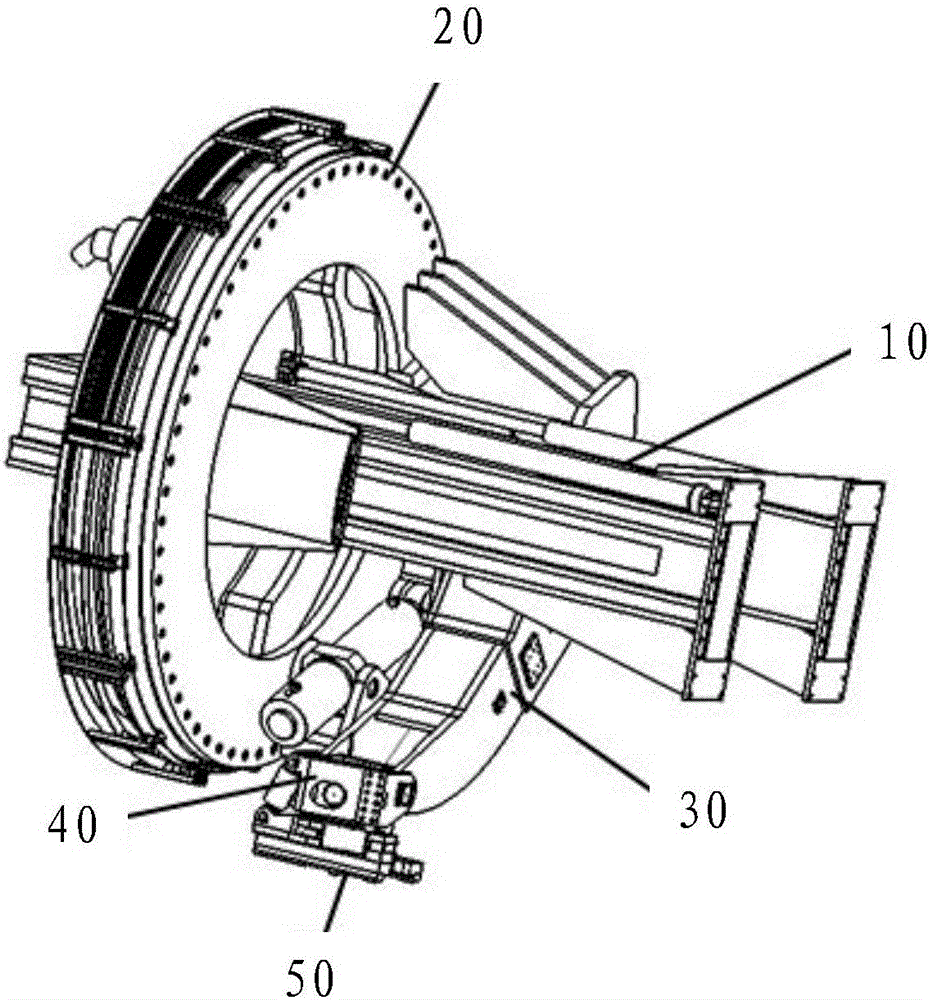

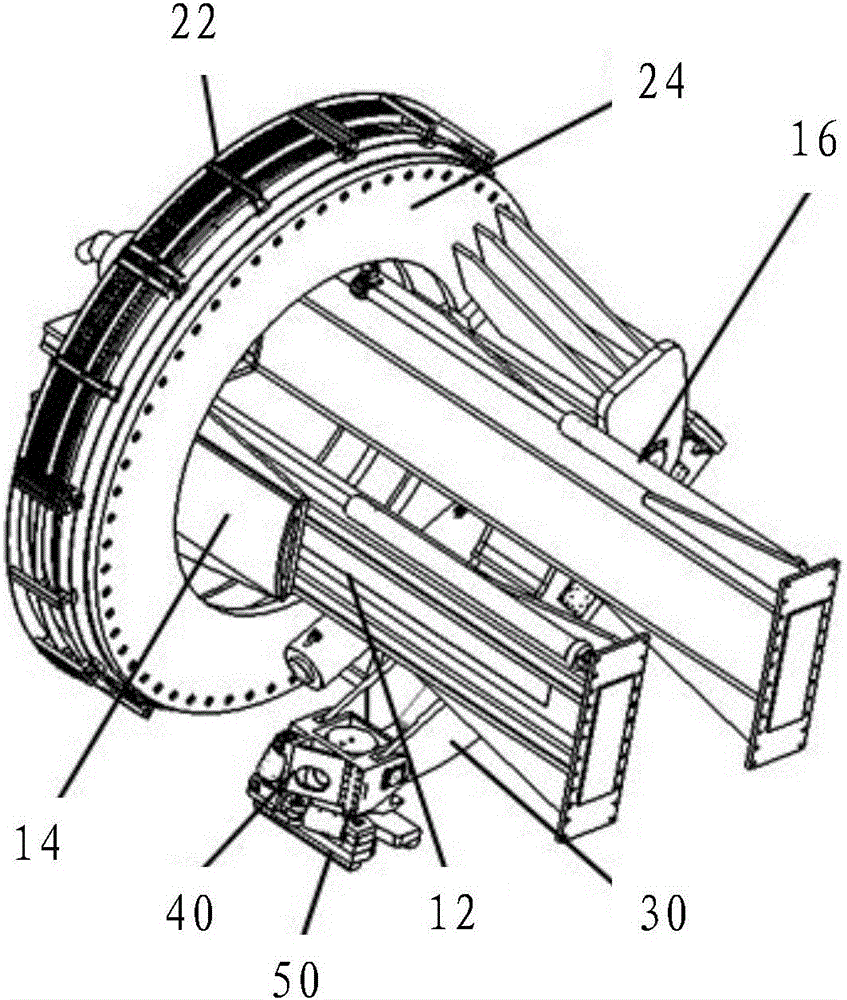

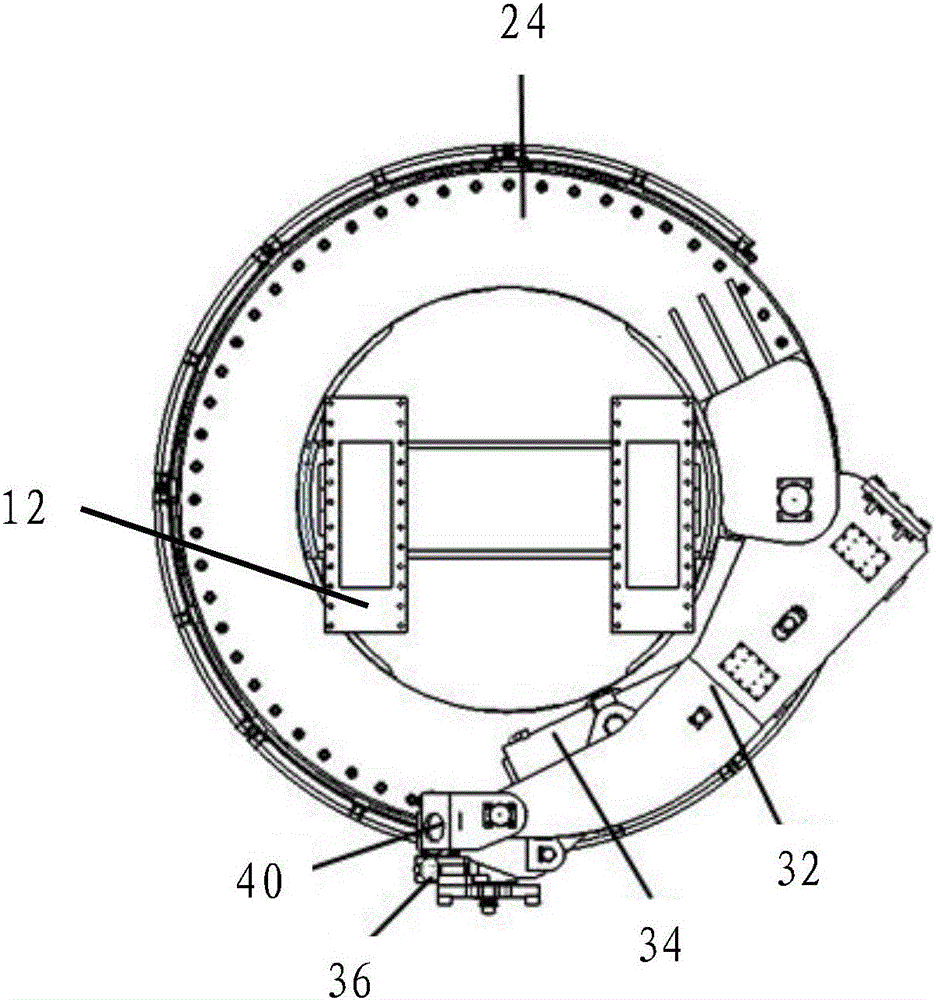

[0051] refer to figure 1As shown, the telescopic single-arm segment assembly machine for rectangular shield tunneling in the present invention includes a translation system 10, a rotary system 20, a telescopic manipulator system 30, a manipulator system 40, a segment clamping device 50 and a motion control system , wherein the translation system 10 is fixed on the shield body and arranged along the axial direction of the rectangular shield segment, and the slewing system 20 is connected to the translation system 10 and moves on the translation system 10 along the axial direction of the rectangular shield segment , the telescopic manipulator system 30 is connected to the slewing system 20 and performs telescopic movement, and the telescopic manipulator system 30 can perform slewing motion along the axis of the rectangular shield segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com