Internal circulation type wood vinegar production and purification device

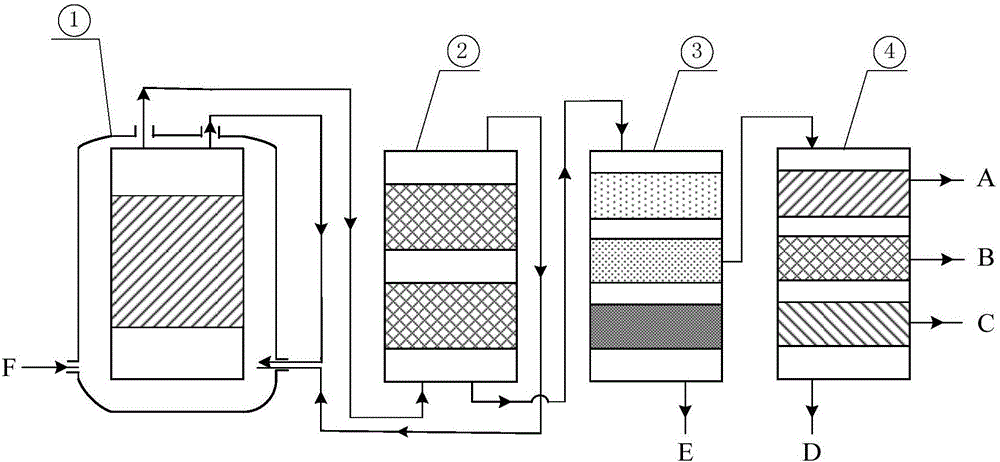

A purification device and technology of wood vinegar, applied in the direction of biofuel, special dry distillation, pyroligneous acid production, etc., to achieve the effect of simple structure, no secondary pollution, and compact combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

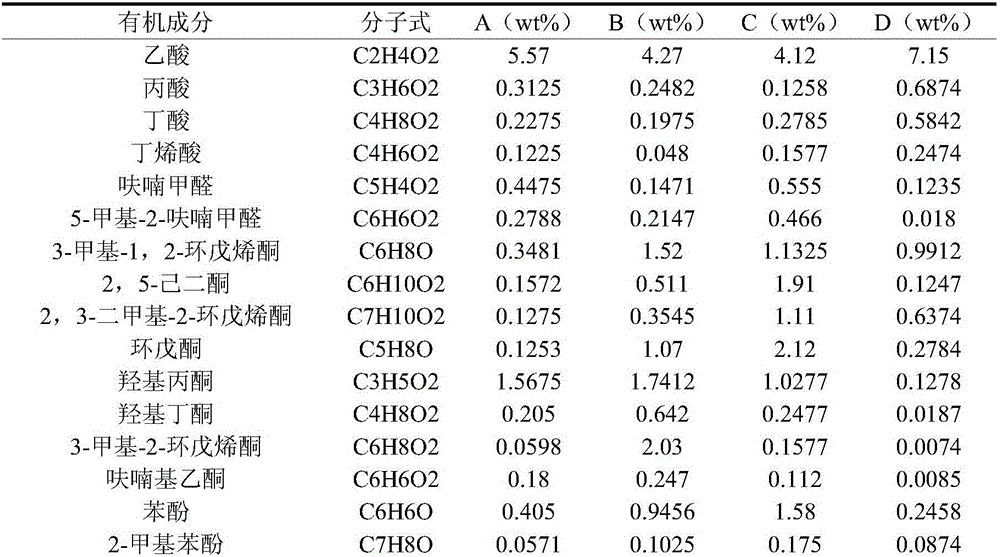

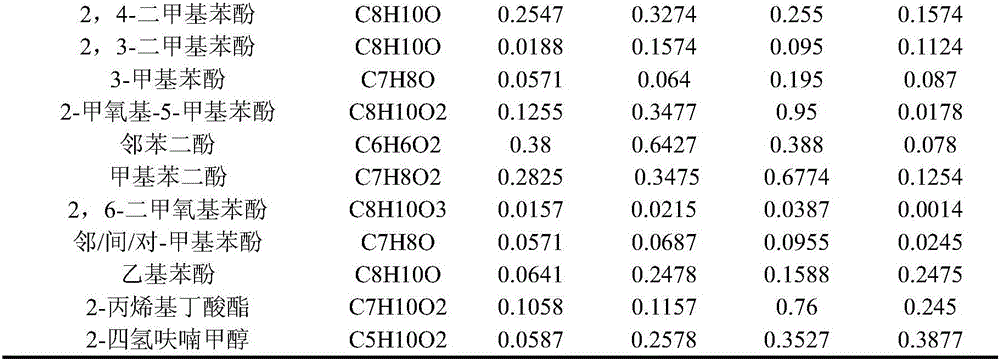

[0031] Preparation of wood vinegar by single treatment of 5kg rice husk

[0032] First check the airtightness of the entire unit.

[0033] Next, weigh a certain quality of rice husk, measure the particle size (0.3-0.45mm as an example), fill it into the furnace, and close the furnace door; weigh 500g of rice husk charcoal and fill it into the purification kettle; select hollow fiber ultrafiltration membranes respectively , nanofiltration membrane and reverse osmosis membrane are connected in series to assemble a refined wood vinegar purification tower.

[0034] Set the temperature of the pyrolysis furnace to 400°C, open the fuel oil valve, and heat the pyrolysis furnace; adjust the gas return valve of the pyrolysis furnace, and the return ratio is 5:1; open the gas return valve in the furnace after heating for 10 minutes, and use the gas Heat the pyrolysis furnace as a heat source; close the fuel oil valve. Set the temperature of the upper and lower sections of the purificat...

Embodiment 2

[0039] Preparation of wood vinegar by single treatment of 5kg corn stalks

[0040] First check the airtightness of the entire unit.

[0041] Next, weigh 5kg of corn stalks, measure the particle size (below 0.2mm as an example), fill them into the furnace, and close the furnace door; weigh 500g of corn stalk charcoal and fill it into the purification kettle; Osmotic membranes are connected in series to assemble a purified wood vinegar purification tower.

[0042] Set the temperature of the pyrolysis furnace to 500°C, open the fuel oil valve, and heat the pyrolysis furnace; adjust the gas return valve of the pyrolysis furnace, and the return ratio is 9:1; open the gas return valve in the furnace after heating for 10 minutes, and use the gas Heat the pyrolysis furnace as a heat source; close the fuel oil valve. Set the temperature of the upper and lower sections of the purification kettle to 300°C and 200°C respectively, open the valve of the liquid outlet in the middle layer o...

Embodiment 3

[0047] Single processing 5kg sawdust to prepare wood vinegar

[0048] First check the airtightness of the entire unit.

[0049] Next, weigh 5kg of sawdust, fill it into the furnace, and close the furnace door; weigh 500g of sawdust charcoal and fill it into the purification kettle; respectively select nanofiltration membranes and reverse osmosis membranes in series to assemble refined wood vinegar purification towers.

[0050] Set the temperature of the pyrolysis furnace to 400°C, open the fuel oil valve, and heat the pyrolysis furnace; adjust the gas return valve of the pyrolysis furnace, with a return ratio of 8:1; open the gas return valve in the furnace after heating for 10 minutes, and use the gas Heat the pyrolysis furnace as a heat source; close the fuel oil valve. Set the temperature of the upper and lower sections of the purification kettle to 250°C and 200°C respectively, open the valve of the liquid outlet in the middle layer of the crude purification kettle, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com