A graphene-nickel composite conductive anticorrosion polysulfide sealant

A polysulfide sealant, composite conductive technology, applied in conductive adhesives, adhesives, adhesive additives, etc., can solve the problems of poor medium resistance and corrosion resistance, achieve good medium resistance, improve conductivity, particle size, etc. small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation of component A and component B is mixed with a three-roll mill, and each component is weighed according to the proportion, then roughly mixed and then mixed with a three-roll mill for 3 times before use;

[0019] Component A and Component B are kept separately.

[0020] The preparation method of the graphene-nickel composite conductive filler in the high-conductivity anti-corrosion polysulfide sealant as described above is characterized in that: graphene and metal nickel powder are mixed and stirred in 95% ethanol aqueous solution, and silane coupling is added in the process. The coupling agent is reacted at a temperature of 50°C to 60°C for 4h to 6h, and then filtered and dried to obtain the product, wherein graphene is highly conductive graphene with layers within 10 layers, preferably graphene with layers within 5 layers; metal nickel powder is granular Powder with a diameter of 5 microns; the silane coupling agent has the following structure: HS(CH ...

Embodiment 1

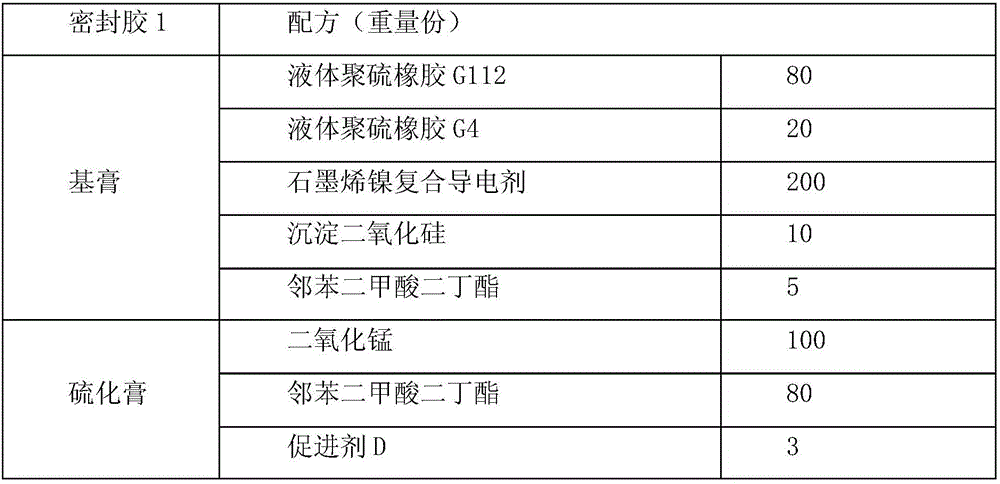

[0022] Embodiment 1: Sealant 1 is a kind of sealant used for the antistatic sealing of aircraft fuel tank, and is made up of component A base paste and component B vulcanized paste, component A is base paste, and component B is vulcanized paste, and its Composition formula is as shown in table 1:

[0023] Formulation composition of table 1 sealant 1

[0024]

[0025] Wherein the synthesis steps of the graphene-nickel composite conductive agent are as follows: take 2 parts by weight of graphene and 200 parts by weight of metal nickel powder with a layer number of about 5 layers, disperse them in 200 mL of 95% ethanol aqueous solution, heat to 50 ° C, Then 0.2 parts by weight of γ-mercaptopropyltrimethoxysilane was added dropwise, stirred for 4 hours, and then filtered, and the obtained solid was dried in a blast drying oven at 90° C. for 2 hours to obtain the product.

[0026] Both the base paste and the vulcanizing paste are prepared by mixing with a three-roll mill, then ...

Embodiment 2

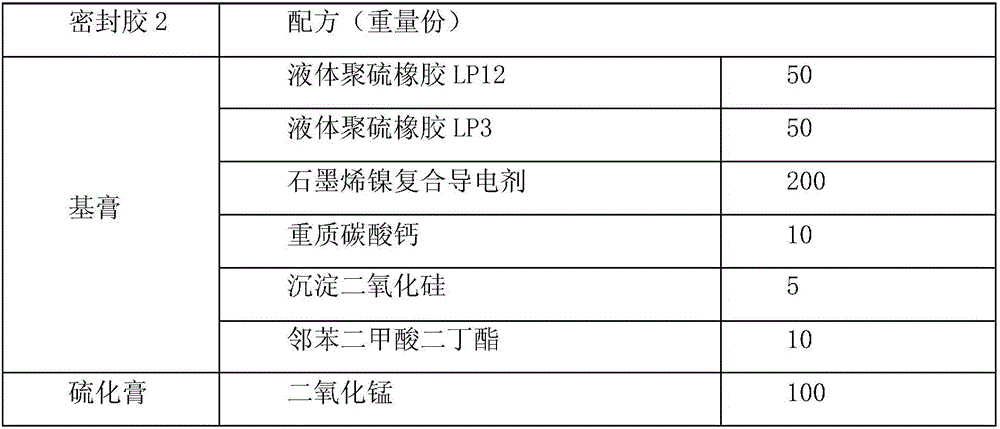

[0028] Sealant 2 is a sealant used for electromagnetic shielding of equipment compartments. It is composed of component A base paste and component B vulcanized paste. Component A is the base paste and component B is the vulcanized paste. 2 shows:

[0029] Formulation composition of table 2 sealant 2

[0030]

[0031]

[0032]Wherein the synthesis steps of the graphene-nickel composite conductive agent are as follows: Weigh 2 parts by weight of graphene and 200 parts by weight of metal nickel powder, disperse them in 200 mL of 95% ethanol aqueous solution, heat to 60 ° C, Then 0.3 parts by weight of γ-mercaptopropyltriethoxysilane was added dropwise, stirred for 5 hours, and then filtered, and the obtained solid was dried in a blast drying oven at 90° C. for 4 hours to obtain the product.

[0033] Both the base paste and the vulcanizing paste are prepared by mixing with a three-roll mill, then weighed according to a weight ratio of 100:8, mixed by hand for 5 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com