Helical structural organic light emitting material and organic light emitting device thereof

A luminescent and electromechanical technology, applied in luminescent materials, electrical solid devices, electrical components, etc., can solve the problems of charge imbalance in the luminescent layer, lower device efficiency, difficult electron flow, etc., and achieve high luminous purity and good thermal stability , the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The synthesis of embodiment 1 compound 10

[0055]

[0056] Synthesis of Intermediate 10-1

[0057] In a three-necked flask, add o-bromoiodobenzene (31g, 110mmol), indole (11.7g, 100mmol), potassium hydroxide (8g, 200mmol), cuprous iodide (1.9g), o-phenanthroline (2.5g ) and o-xylene (400mL), heated to reflux under nitrogen protection for 12 hours, cooled, added dichloromethane and water, the organic layer was dried and concentrated, and the crude product was purified by column chromatography to obtain 23g, with a yield of 85%.

[0058] Synthesis of Intermediate 10-2

[0059] In the three-necked flask, add intermediate 10-1 (15g, 55.3mmol) and 150mL dry tetrahydrofuran, cool to minus 78 degrees under nitrogen protection, and then slowly add 2M n-butyllithium n-hexane solution (27.5mL, 55.3 mmol), reacted at this temperature for 1 hour, then slowly added dropwise a tetrahydrofuran solution (14 g, 55.3 mmol) dissolved with 2-bromofluorenone, after the drop was comple...

Embodiment 2

[0062] The synthesis of embodiment 2 compound 19

[0063]

[0064] Synthesis of Intermediate 19-1

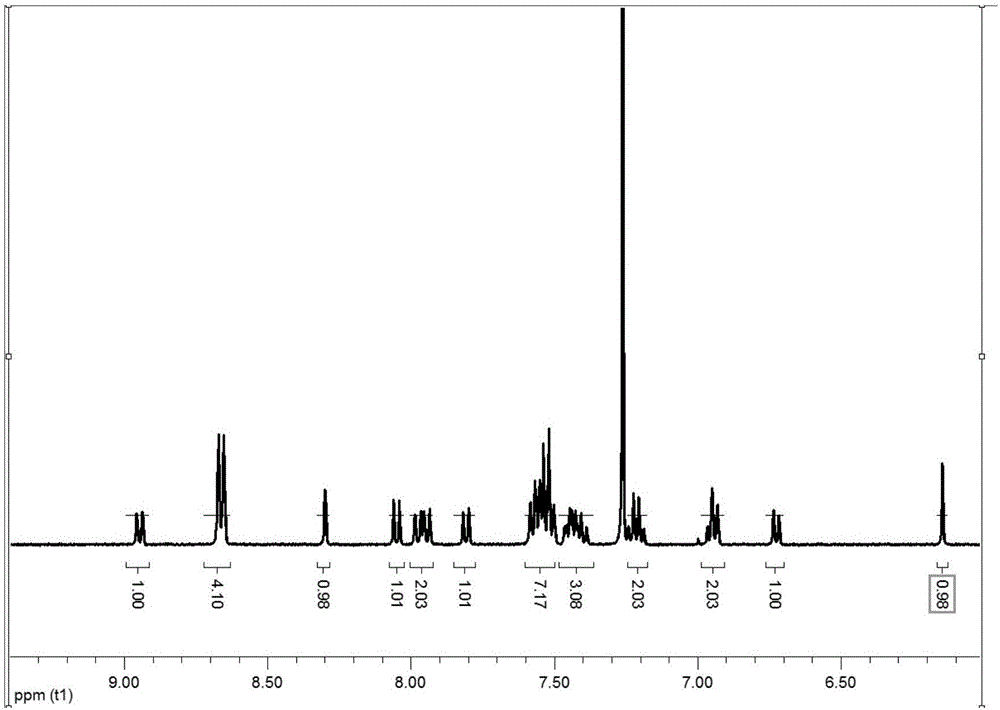

[0065] In a three-necked flask, add intermediate 10-2 (5g, 11.5mmol), pinacol diboronate (4.4g, 17mmol), potassium acetate (2.2g, 23mmol), dichloroditriphenylphosphine palladium (0.5 g) and dioxane (50mL), heated to reflux under nitrogen protection for 10 hours, cooled, removed the solvent, added dichloromethane, washed with water, dried, concentrated by filtration, and the crude product was recrystallized with ethanol to obtain 4.4g, yield 80% . NMR such as figure 1 .

[0066] Synthesis of Compound 19

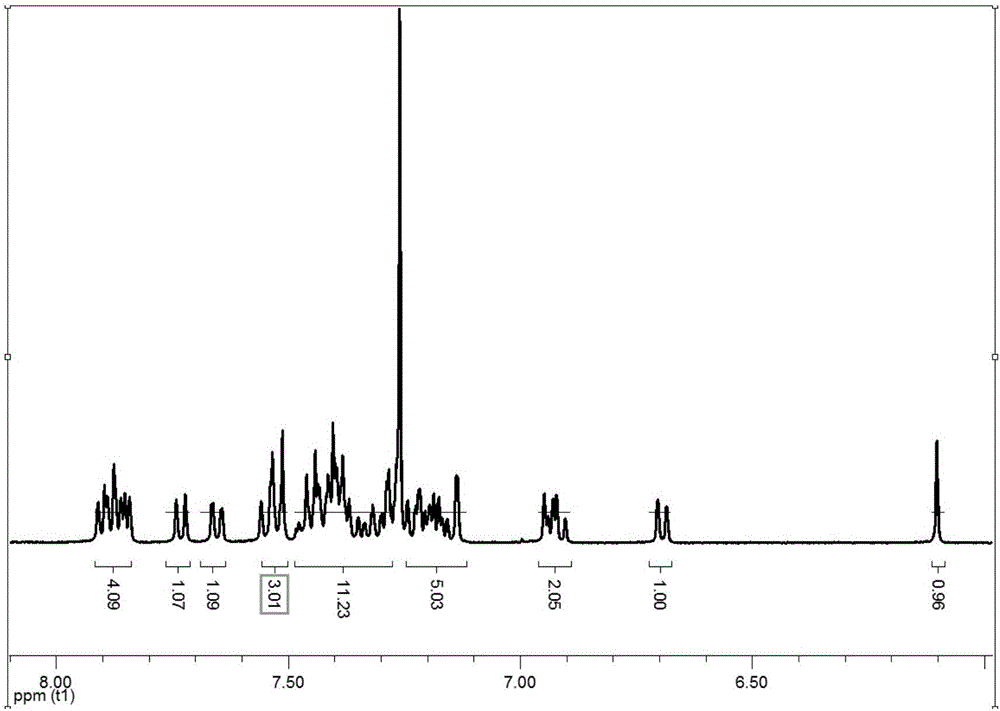

[0067] In a flask, add intermediate 19-1 (2 g, 4.2 mmol), 2-chloro-4,6-diphenyl-1,3,5-triazine (1.1 g, 4.2 mmol), potassium carbonate (1.1 g , 8.4mmol), tetrakistriphenylphosphine palladium (100mg), 20mL of tetrahydrofuran and 10mL of water, heated to reflux for 10 hours under nitrogen protection, cooled, added dichloromethane to extract and separate layers, the organic ...

Embodiment 3

[0068] The synthesis of embodiment 3 compound 24

[0069]

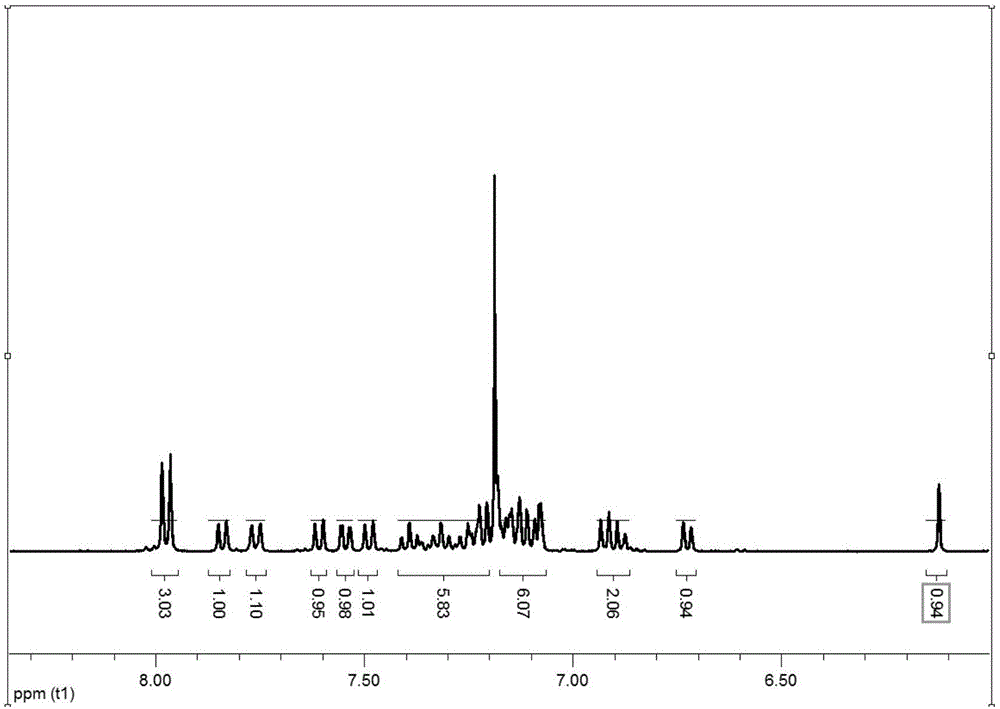

[0070] The synthesis method is the same as that of compound 10, except that 9-(2-naphthyl)-anthracene-10- Except for boric acid, the yield is 85%. NMR such as figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com