Solidified granular soil produced by utilizing waste and old materials from building project

A technology of construction engineering and aggregates, which is applied in construction, solid waste management, sustainable waste treatment, etc., can solve the problems that the base and subbase of composite solidified soil pavement are not allowed to be used, the stability of the roadbed is unfavorable, and damage cannot be prevented. , to achieve significant environmental and economic benefits, improve performance and reduce the amount of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

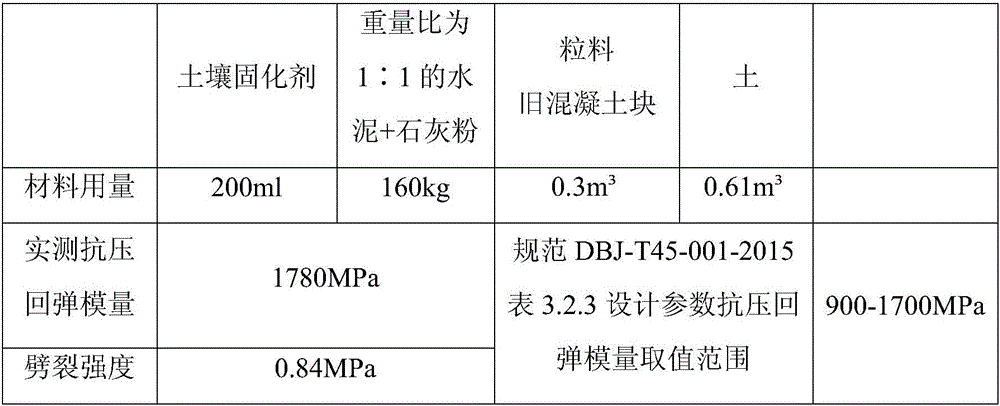

[0040] Table 2 Example 2: The material composition of every 1 cubic meter of solidified granular soil

[0041]

Embodiment 3

[0042] Table 3 Example 3: The material composition of every 1 cubic meter of solidified granular soil

[0043]

[0044] Table 4 Example 4: The material composition of every 1 cubic meter of solidified granular soil

[0045]

[0046] Table 5 Example 5: The material composition of every 1 cubic meter of solidified granular soil

[0047]

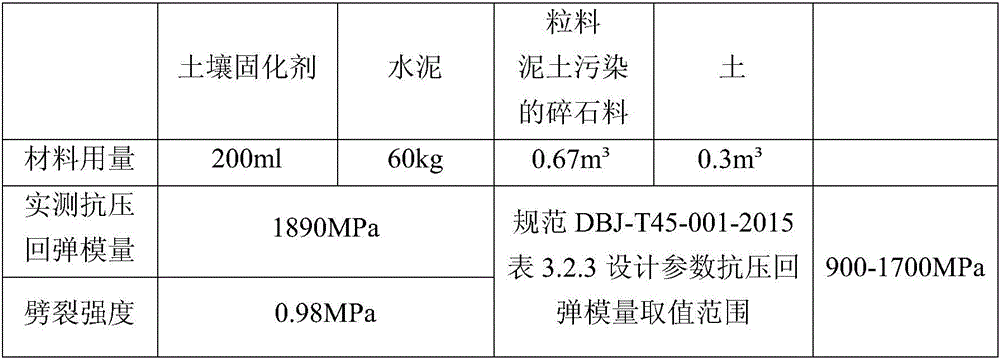

[0048] Table 6 Example 6: The material composition of every 1 cubic meter of solidified granular soil

[0049]

Embodiment 7

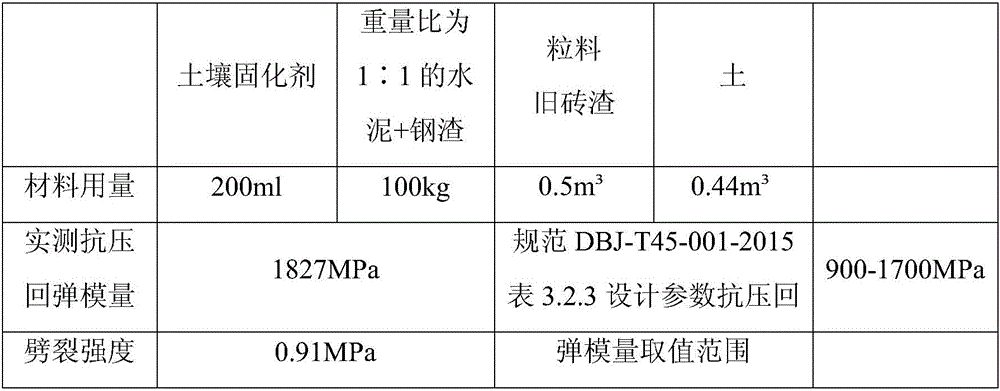

[0050] Table 7 Example 7: The material composition of every 1 cubic meter of solidified granular soil

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com