Phosphorus-containing magnesium oxychloride cement preparation method beneficial to improvement of early strength

A magnesium oxychloride and early strength technology, which is applied in the field of preparation of phosphorus-containing magnesium oxychloride cement, can solve the problems of low early strength, slow setting speed, and speed up the early hydration and crystallization speed of magnesium oxychloride cement, so as to improve the early strength , the effect of increasing the speed and yield, reducing the nucleation barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

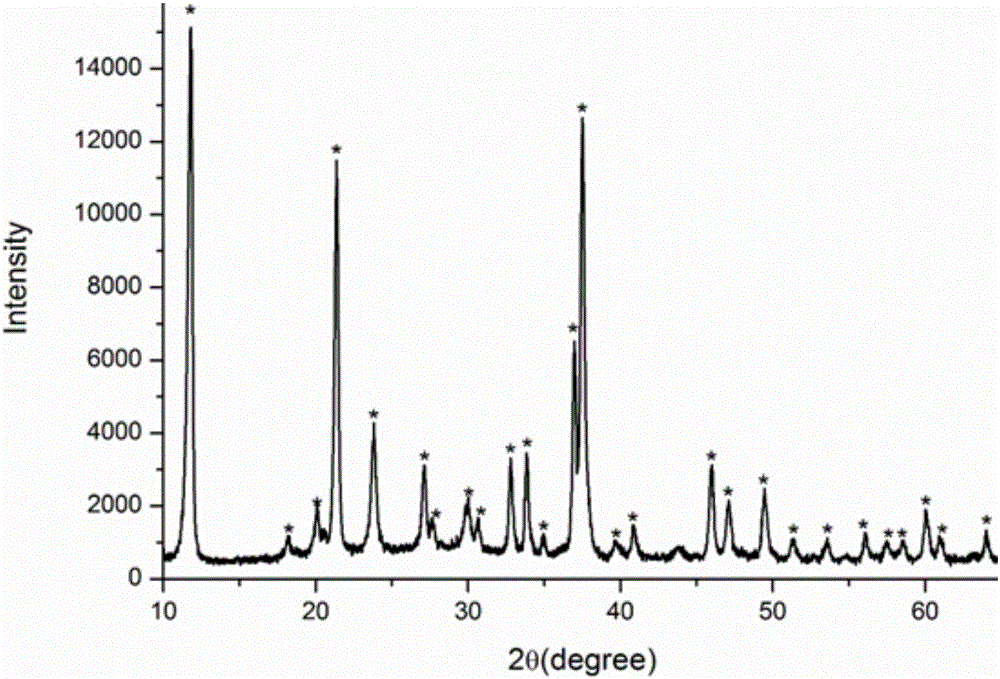

Image

Examples

Embodiment 1

[0018] (1) Calcining basic magnesium carbonate at 600°C for 2 hours to obtain high-activity magnesium oxide powder, mix the magnesium oxide powder with magnesium chloride and water in a molar ratio of 0.32:1:13 and put it into a hydrothermal reaction kettle for 80 React at ℃ for 3 days, after cooling, filter with suction, wash with absolute ethanol, dry in an oven at 45℃ and dry to obtain seed crystal powder;

[0019] (2) The mass content of active magnesium oxide in the light-burned magnesium oxide powder used in the present embodiment is 63%, and the mass content of magnesium oxide is 84.27%,

[0020] According to MgO, magnesium chloride, the molar ratio of water is 6:1:13, the consumption of anti-water agent phosphoric acid is 1% of MgO quality, the consumption of seed crystal is 1% of MgO quality, the crystal that obtains in the step (1) is first Seed and the above-mentioned light-burned magnesia powder are mixed evenly, and magnesium chloride is dissolved in water and pho...

Embodiment 2

[0022] (1) The preparation of seed crystal powder is the same as in Example 1;

[0023] (2) According to MgO, magnesium chloride, the mol ratio of water is 6:1:15, the consumption of anti-water agent sodium dihydrogen phosphate is 1% of MgO quality, and the consumption of crystal seed is 1% of MgO quality, step ( 1) The seed crystal obtained in and the same light-burned magnesia powder as in Example 1 were mixed uniformly, magnesium chloride was dissolved in water and sodium dihydrogen phosphate was added to mix uniformly, and finally the mixed powder and solution were mixed and stirred uniformly to prepare Form magnesium oxychloride cement slurry, inject this magnesium oxychloride cement slurry into the stainless steel mold of 40mm * 40mm * 160mm, demould curing after 1 day, the compressive strength when curing in air for 3 days is 75MPa; And here During the process, it was detected that the free magnesium chloride in the system was greatly reduced, which also confirmed that ...

Embodiment 3

[0025] (1) The preparation of seed crystal powder is the same as in Example 1;

[0026] (2) According to MgO, magnesium chloride, the mol ratio of water is 7:1:15, the consumption of anti-water agent ammonium dihydrogen phosphate is 1% of MgO quality, and the consumption of crystal seed is 1% of MgO quality, step ( 1) The seed crystal obtained in and the same light-burned magnesia powder as in Example 1 were mixed uniformly, magnesium chloride was dissolved in water and ammonium dihydrogen phosphate was added to mix uniformly, and finally the mixed powder and solution were mixed and stirred uniformly to prepare Form magnesium oxychloride cement slurry, inject this magnesium oxychloride cement slurry into the stainless steel mold of 40mm * 40mm * 160mm, demould curing after 1 day, the compressive strength when curing in air for 3 days is 68MPa; And here During the process, it was detected that the free magnesium chloride in the system was greatly reduced, which also confirmed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com