Strong shear type central jet cavitation generator

A strong shearing and generator technology, applied in the field of hydraulic cavitation, can solve problems such as weak shearing effect, poor cavitation effect, and weak cavitation intensity, and achieve enhanced fluid turbulence, improved turbulence, The effect of improving the shear speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

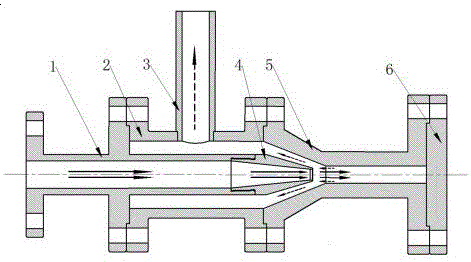

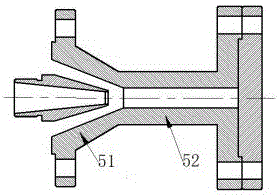

[0022] A strong shear type central jet cavitation generator, comprising an outlet pipe 3, a high-pressure water supply pipe 1, an outlet chamber 2, and a tubular return water chamber 5 connected coaxially and communicated in sequence; the outlet pipe 3 and the outlet pipe The flow chamber 2 is connected; the outer end of the return water chamber 5 is provided with a baffle 6; the outlet end of the high-pressure water supply pipe 1 is located in the outflow chamber 2; the outlet end of the high-pressure water supply pipe 1 is provided with a nozzle 4; The water chamber 5 includes a conical pipe 51 and a throat pipe 52 connected in sequence toward the baffle plate 6 ;

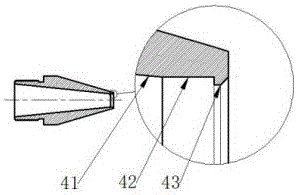

[0023] The inner diameter of the nozzle 4 gradually decreases along the water flow direction, which is a tapered section 41; the liquid outlet end of the nozzle 5 is provided with a straight pipe section 42; Taiwan 43.

[0024] The inner diameter of the throat pipe 52 is larger than the inner diameter of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com