A hydraulic independent drive system for a vehicle

An independent drive and power system technology, applied to vehicle components, vehicle energy storage, hybrid vehicles, etc., can solve the problems of no energy recovery system and low efficiency, so as to increase the range of speed regulation, reduce the burden on the driver, and improve the battlefield The effect on viability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with examples and accompanying drawings. It should be noted that the following embodiments are only illustrative, and are not intended to limit the present invention.

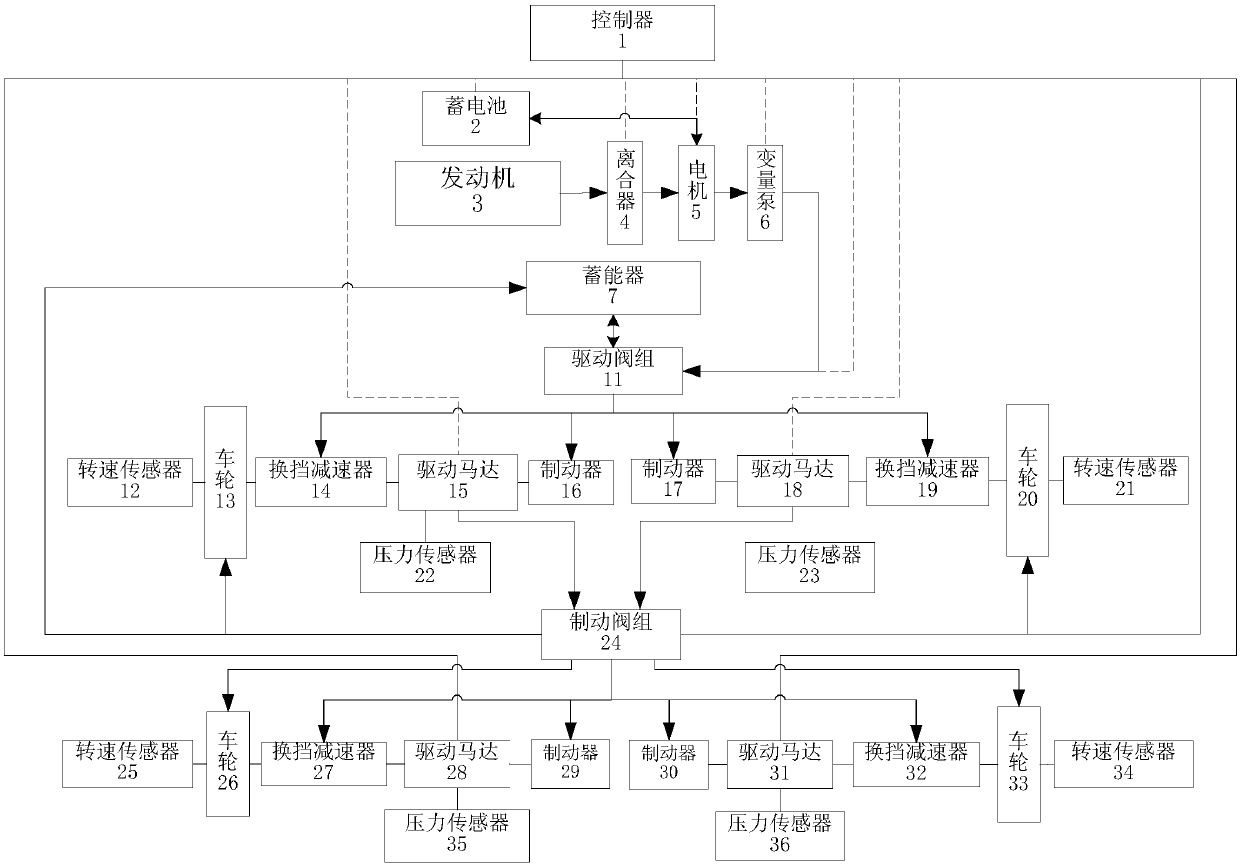

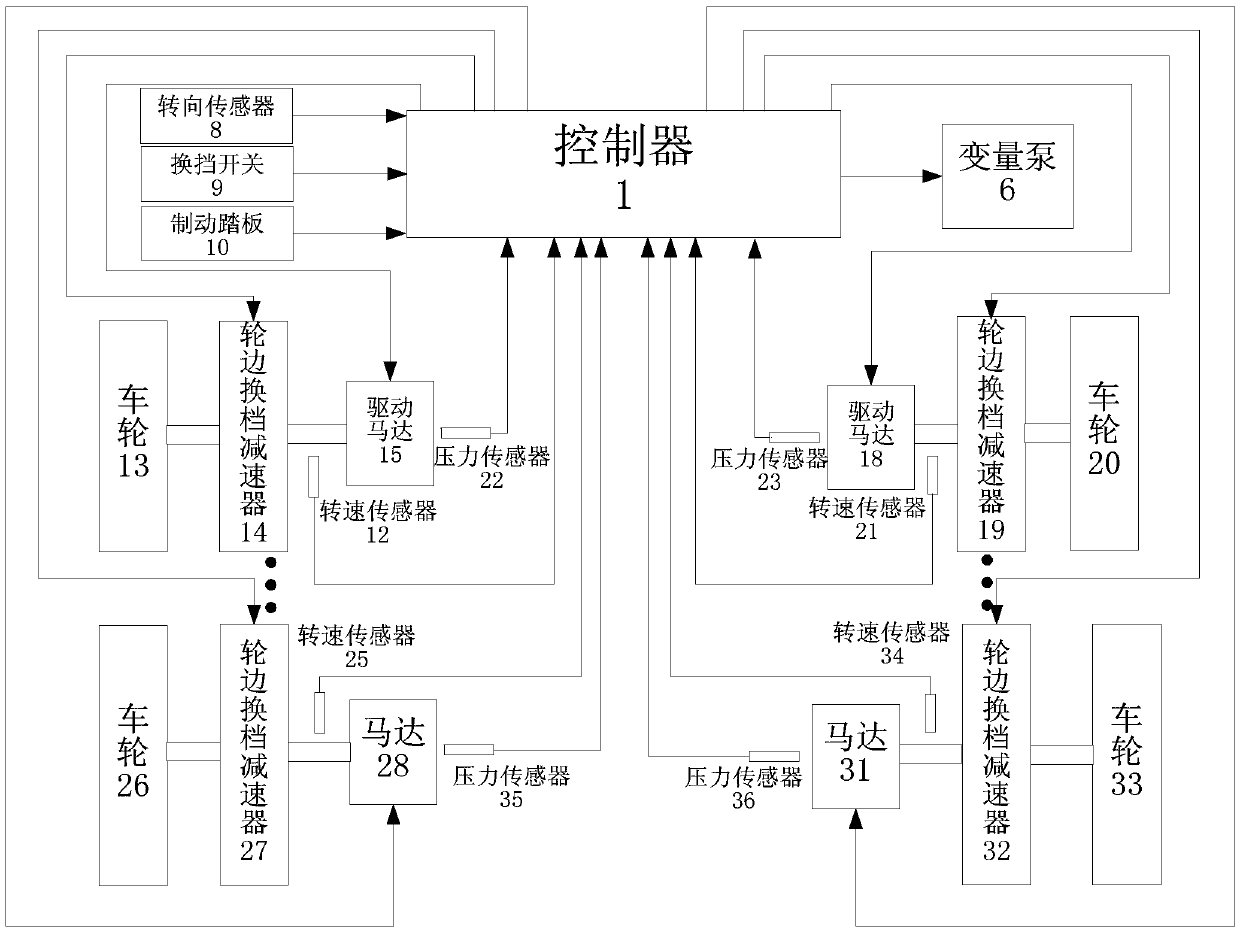

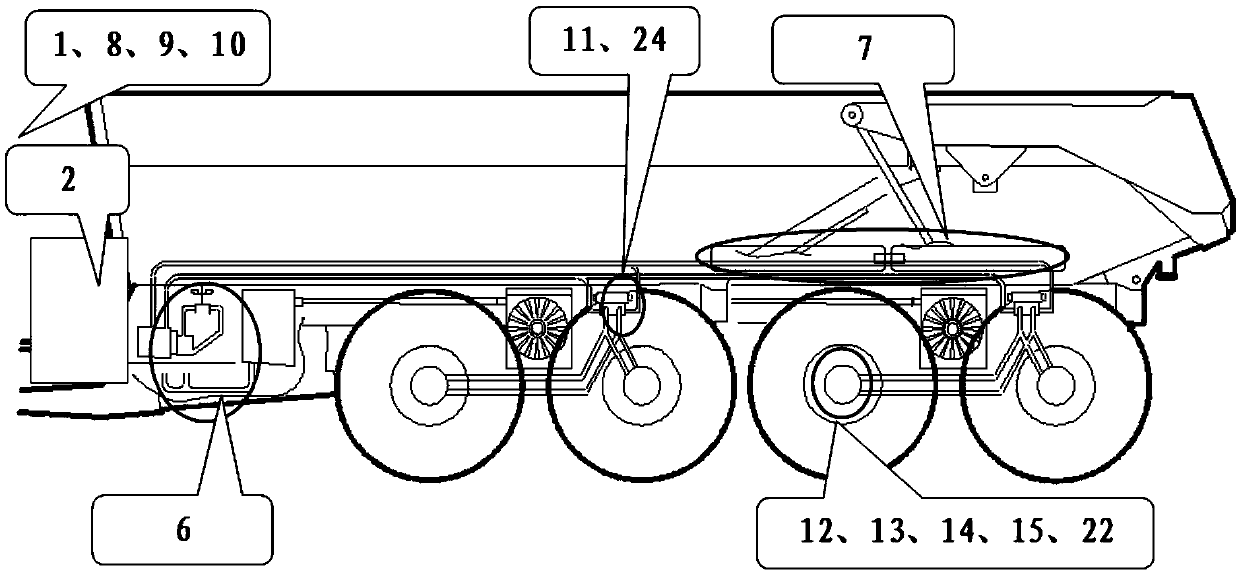

[0047] like figure 1 As shown, the hydraulic independent drive system of the present invention is mainly composed of a controller 1, a battery 2, an engine 3, a clutch 4, a motor 5, a variable pump 6, an accumulator 7, a steering sensor 8, a shift switch 9, and a brake pedal 10 , drive valve group 11, speed sensor 12, 21, 25, 34, wheel 13, 20, 26, 33, wheel shift reducer 14, 19, 27, 32, drive motor 15, 18, 28, 31, brake 16, 17, 29, 30, pressure sensors 22, 23, 35, 36, brake valve group 24 and so on.

[0048] Rotational speed sensor 12, wheel 13, wheel-side gear shift reducer 14, drive motor 15, brake 16 are installed on the same shaft successively, and pressure sensor 22 is installed in the high-pressure cavity of drive motor 15. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com