Oxidation-resistant high-temperature-resistant polytetrafluoroethylene film covered filter material, and preparation method thereof

A polytetrafluoroethylene film and polytetrafluoroethylene technology, which is applied in the field of plastic films, can solve the problems of easy thermal oxidation degradation reaction, poor thermal stability, insufficient adhesive strength, etc., and achieve excellent thermal oxidation stability and electrical insulation. resistance, excellent heat resistance and electrical insulation, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

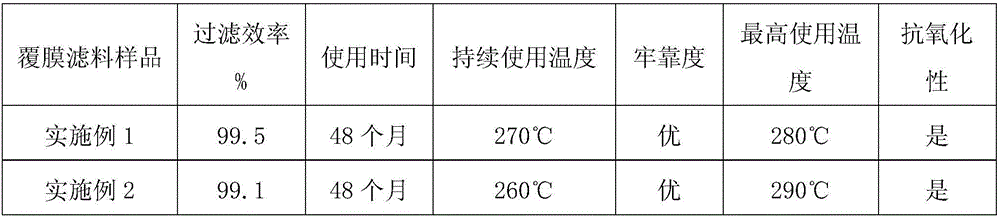

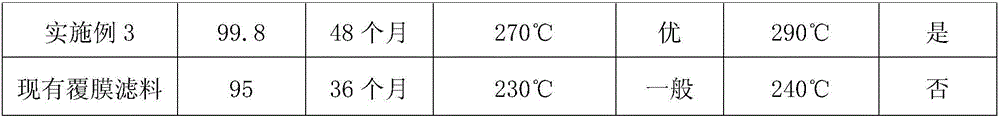

Embodiment 1

[0041] The anti-oxidation and high temperature resistant polytetrafluoroethylene film-coated filter material proposed by the present invention includes upper, middle and lower layers; the upper layer is a polytetrafluoroethylene film layer, the middle layer is a polytetrafluoroethylene bonding layer, and the lower layer is a filter material layer ; wherein: the polytetrafluoroethylene film layer is mainly made of the following raw materials in parts by weight: 8 parts of polytetrafluoroethylene, 0.5 part of antioxidant, 0.5 part of acetyl triethyl citrate, 1 part of molybdenum disulfide, 2 parts of tribasic lead sulfate, 1 part of dibasic lead phosphite, and 1 part of polysiloxane; the polytetrafluoroethylene bonding layer is mainly made of the following raw materials in parts by weight: polytetrafluoroethylene dispersed 2 parts of liquid, 0.5 parts of anti-aging agent, 1.5 parts of foaming agent and 0.5 parts of thickener; the filter material layer is mainly made of the follow...

Embodiment 2

[0050] The anti-oxidation and high temperature resistant polytetrafluoroethylene film-coated filter material proposed by the present invention includes upper, middle and lower layers; the upper layer is a polytetrafluoroethylene film layer, the middle layer is a polytetrafluoroethylene bonding layer, and the lower layer is a filter material layer ; Wherein: the polytetrafluoroethylene film layer is mainly made of the following raw materials in parts by weight: 10 parts of polytetrafluoroethylene, 1.5 parts of antioxidant, 1.5 parts of acetyl triethyl citrate, 2 parts of molybdenum disulfide, 4 parts of tribasic lead sulfate, 1.5 parts of dibasic lead phosphite, and 2 parts of polysiloxane; the polytetrafluoroethylene bonding layer is mainly made of the following raw materials in parts by weight: polytetrafluoroethylene dispersed 3 parts of liquid, 1.5 parts of anti-aging agent, 2.5 parts of foaming agent and 1.5 parts of thickener; the filter material layer is mainly made of th...

Embodiment 3

[0058] The anti-oxidation and high temperature resistant polytetrafluoroethylene film-coated filter material proposed by the present invention comprises upper, middle and lower layers; the upper layer is a polytetrafluoroethylene film layer with high temperature resistance function, the middle layer is a polytetrafluoroethylene bonding layer, The lower layer is a filter material layer with a supporting function; the polytetrafluoroethylene film layer is mainly made of the following raw materials in parts by weight: 9 parts of polytetrafluoroethylene, 1 part of antioxidant, 0.8 part of acetyl triethyl citrate , 1.5 parts of molybdenum disulfide, 3 parts of tribasic lead sulfate, 1.2 parts of dibasic lead phosphite and 1.5 parts of polysiloxane; the polytetrafluoroethylene bonding layer is mainly made of the following raw materials in parts by weight of: 2.5 parts of polytetrafluoroethylene dispersion, 1.5 parts of anti-aging agent, 2 parts of foaming agent and 1.2 parts of thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com