Weight increment and weight loss integral mixing device

A technology of mixing device and extrusion device, which is applied in the field of integrated mixing device for weight gain and weight loss, can solve the problems of lack of precise batching and rice weight control device, inability to strictly control rice weight, and inability to control the weight of unloaded rice, so as to avoid Raw material waste, guaranteed constant, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

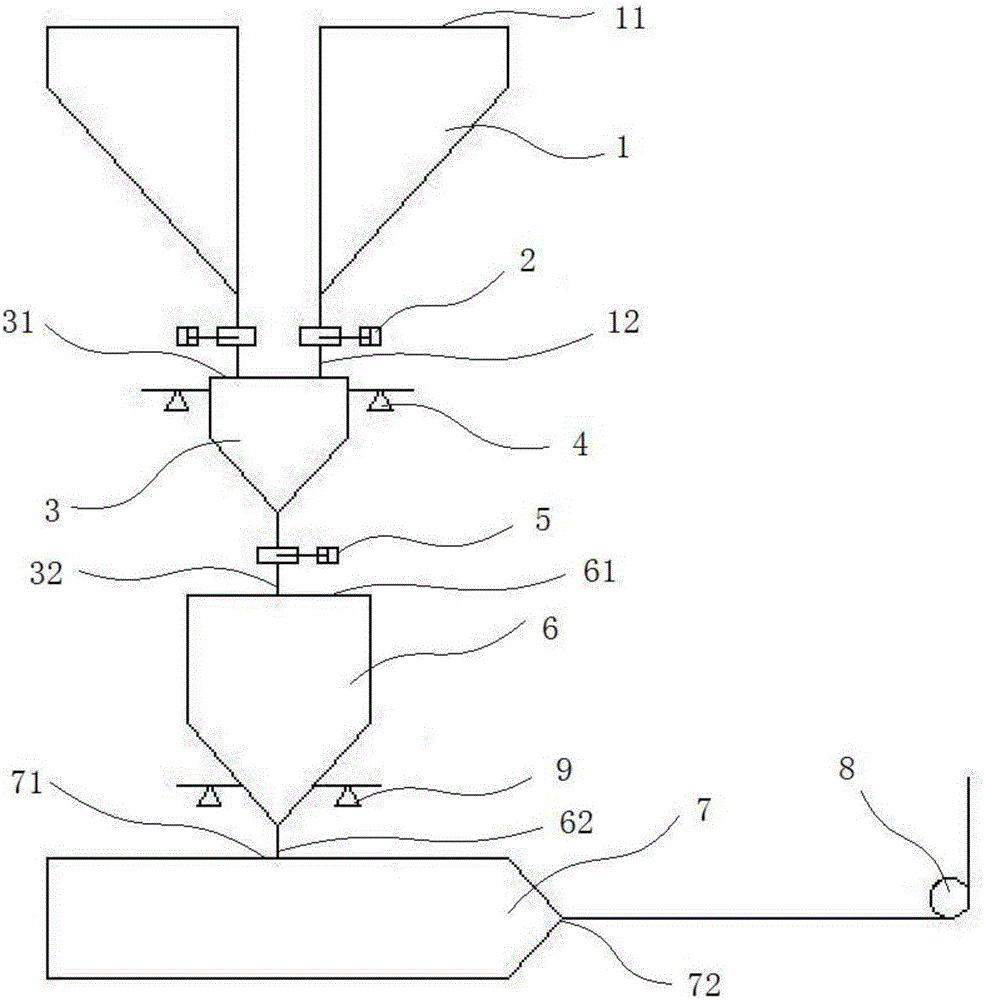

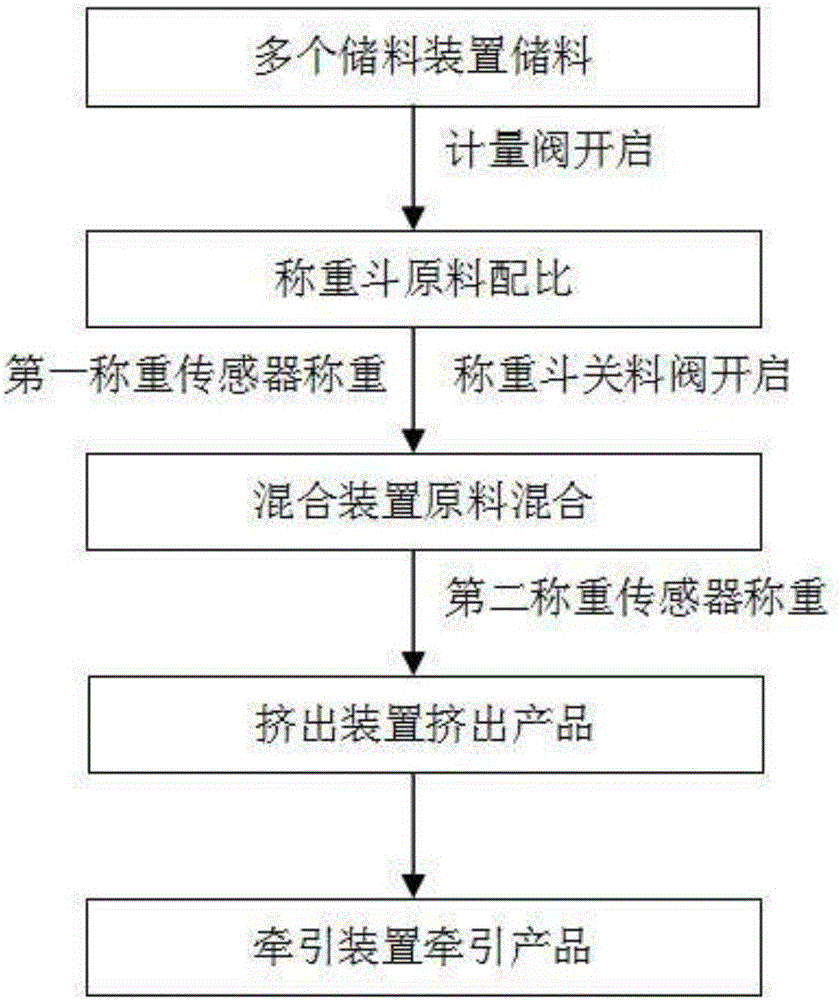

[0027] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach figure 2 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0028] figure 1 It is a structural diagram of an embodiment of a weight-gain-loss integrated mixing device of the present invention. Such as figure 1 As shown, the weight gain and weight loss integrated mixing device provided in this embodiment includes: a material storage device 1, a material storage inlet 11, a material storage outlet 12, a metering valve 2, a weighing bucket 3, a weighing inlet 31, and a weighing outlet 32 , the first weighing sensor 4, the weighing hopper closing material valve 5, the mixing device 6, the mixing inlet 61, the mixing outlet 62, the second weighing sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com