Submerged type pipeline welding joint polishing robot based on modular design

A modular design, robotic technology, applied in machine tools designed for grinding the rotating surface of workpieces, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of honing machines that are difficult to find pipes, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

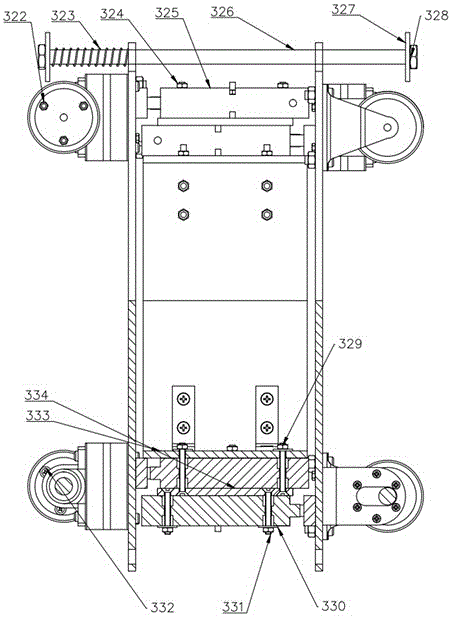

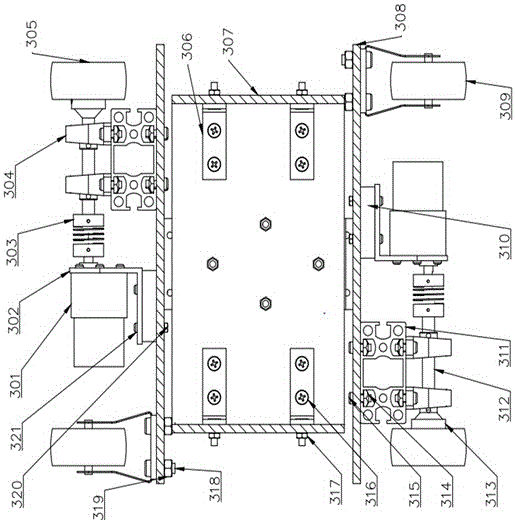

[0021] as attached figure 1 , attached figure 2 As shown, the parts of the power module include: DC motor 301, motor bracket 302, coupling 303, bearing 304, driving wheel 305, angle iron 306, side baffle plate 307 in the middle part, bottom plate 308, driven wheel 309, motor bracket pad 310, bearing spacer 311, power wheel axle 312, connecting part of power wheel and wheel axle 313, T-shaped nut 314, screw 315, screw 316, nut 317, screw 318, nut 319, screw 320, nut 321, power wheel fixing screw 322, spring 323, cylinder fixing screw 324, double-axis cylinder 325, slide rod 326 connecting the power module to the universal joint, slide bar stopper 327, slide bar stopper fixing nut 328, cylinder fixing nut 329, double-axis cylinder 330, Cylinder fixing nut 331 , power wheel fixing nut 332 , fixing plate 333 between cylinders, middle part front baffle plate 334 .

[0022] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com