Welding stick embedding vacuum electron beam welding method

A technology of vacuum electron beam and welding method, which is applied in electron beam welding equipment, welding equipment, welding/welding/cutting objects, etc., can solve the problems of easy crack formation in welded joints, large thermal stress, restricted application, etc. Carbon Equivalent and Weld Crack Susceptibility Index, High Energy Density, Effects of Reduced Assembly Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

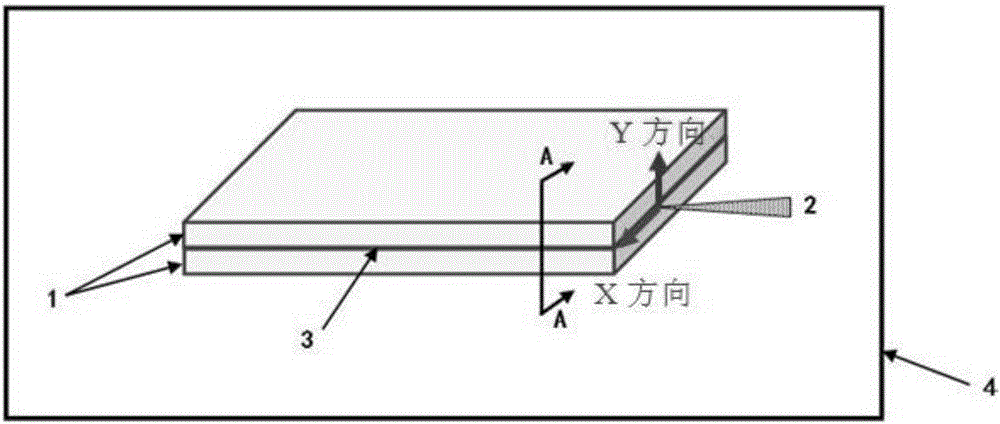

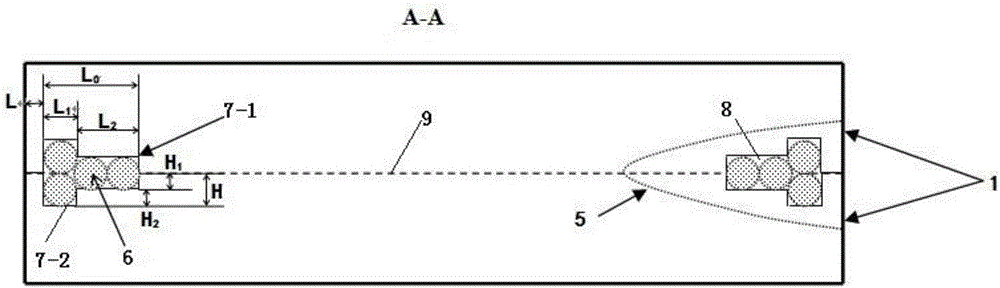

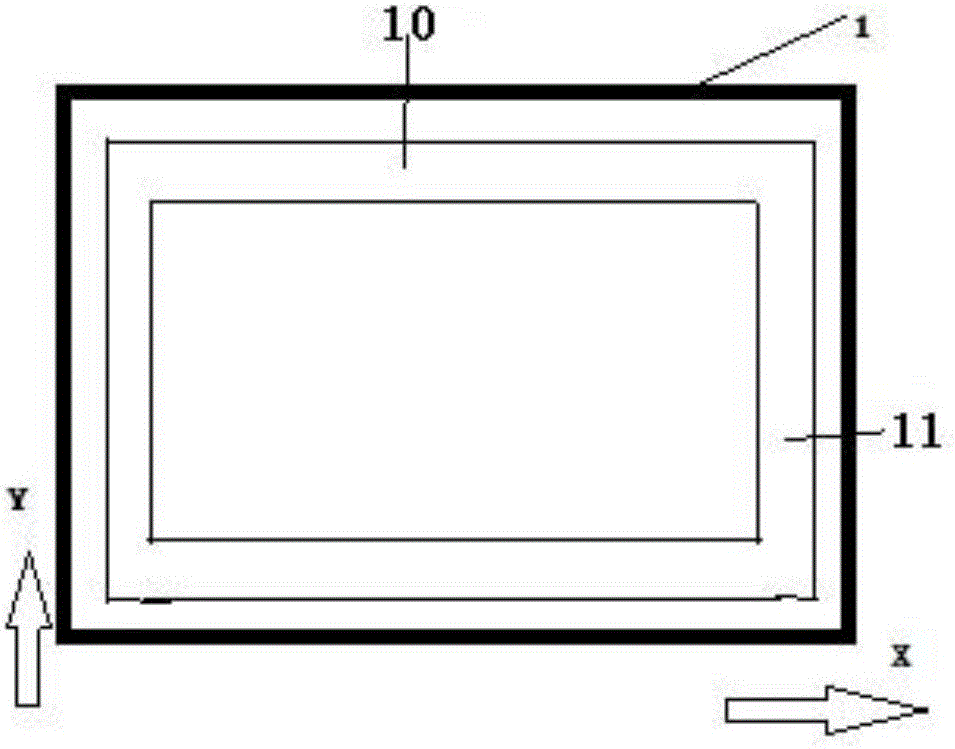

Method used

Image

Examples

Embodiment 1

[0029] In this example, two pieces of 270mm×2100mm×4100mm (thickness×width×length) EH36 continuous casting blanks were used to prepare 534±2mm×2100mm×4100mm (thickness×width×length) EH36 composite blanks by vacuum electron beam welding for Rolling produces extra-thick steel plates.

[0030] The chemical composition of the EH36 continuous casting slab by weight percentage is: C 0.11%, Si 0.28%, Mn 1.46%, P0.011%, S 0.002%, Cu 0.12%, Ni 0.25%, V 0.059%, Nb 0.042% , Ti 0.018%, Als0.27%, the balance is Fe and unavoidable impurities.

[0031] Described a kind of pre-embedded wire vacuum electron beam welding method comprises the following steps:

[0032](1) Using two EH36 continuous casting slabs (or thick steel plates) with the same width and length as raw materials, respectively mill and clean the upper surfaces (or lower surfaces) of the two continuous casting slabs (or thick steel plates), the surfaces must not There are oil stains, iron filings, etc.;

[0033] (2) Boring an...

Embodiment 2

[0039] In this example, two pieces of 300mm×2200mm×3900mm (thickness×width×length) 12Cr2Mo1R continuous casting blanks were used to prepare 592±4mm×2200mm×3900mm (thickness×width×length) 12Cr2Mo1R composite blanks by vacuum electron beam welding. Rolling produces extra-thick steel plates.

[0040] The chemical composition of the 12Cr2Mo1R continuous casting slab by weight percentage is: C 0.10%, Si 0.23%, Mn0.51%, P 0.0051%, S 0.0023%, Cr 2.32%, Mo 0.97%, Als 0.22%, and the balance is Fe and unavoidable impurities.

[0041] Described a kind of pre-embedded wire vacuum electron beam welding method comprises the following steps:

[0042] (1) Using two 12Cr2Mo1R continuous casting slabs (or thick steel plates) with the same width and length as raw materials, respectively mill and clean the upper surfaces (or lower surfaces) of the two continuous casting slabs (or thick steel plates). There are oil stains, iron filings, etc.;

[0043] (2) Boring and milling stepped grooves alon...

Embodiment 3

[0049] In this example, two 250mm×1820mm×2900mm (thickness×width×length) Q890D blanks were used to prepare 494±3mm×1820mm×2900mm (thickness×width×length) Q890D composite blanks by vacuum electron beam welding for rolling Production of extra-thick steel plates.

[0050] The chemical composition of the Q890D continuous casting slab by weight percentage is: C 0.09%, Si 0.25%, Mn 1.68%, P 0.0012%, S 0.0031%, Cr 0.44%, Mo 0.47%, Ni 0.49, V 0.053, Nb 0.027 , Ti 0.023, B0.002%, Als 0.26%, the balance is Fe and unavoidable impurities.

[0051] Described a kind of pre-embedded wire vacuum electron beam welding method comprises the following steps:

[0052] (1) Using two Q890D continuous casting slabs (or thick steel plates) with the same width and length as raw materials, respectively mill and clean the upper surfaces (or lower surfaces) of the two continuous casting slabs (or thick steel plates), the surfaces must not There are oil stains, iron filings, etc.;

[0053] (2) Boring an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com