Powder sintering molding method and mold

A technology of sintering molding and molding method, which is applied in the field of electric heating metal powder sintering, can solve the problems of large shunt current and influence on heating effect, and achieve the effects of increasing current density, optimizing heating effect, and reducing power load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

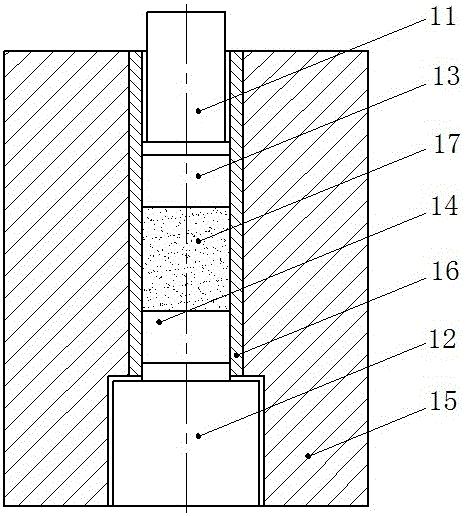

[0024] In this embodiment, the method used here is specifically the SPS molding method.

[0025] The method is to install the powder material in the concave mold and feed the heating current, and carry out discharge plasma heating on the powder material under the condition that the concave mold is prevented from shunting the heating current, so that the powder material is sintered and formed under pressure. Wherein the sintering molding is carried out under vacuum conditions, avoiding the shunting heating current of the concave mold is realized by using a composite concave mold or setting the concave mold as an insulating concave mold, and the composite concave mold includes an outer layer and an inner layer arranged in the outer layer. Insulation on walls. The outer layer of the composite die is made of graphite, and the insulating layer material is made of insulating ceramics, of which the insulating ceramic material is Al with a content greater than 95%. 2 o 3 Ceramics (o...

Embodiment 2

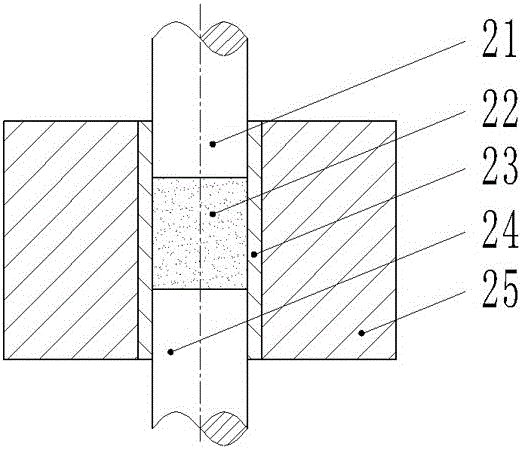

[0028] In this embodiment, the method adopted here is specifically a powder warm pressing molding method.

[0029] The method is suitable for compression molding below 900°C, and the powder metallurgy molding is performed on a press with a heating power supply. In the method, the powder material is installed in the concave mold and a heating current is passed through, and the powder material is subjected to resistance heating under the condition that the concave mold is prevented from shunting the heating current, so that the powder material is sintered and formed under pressure. Avoiding the shunting of the heating current by the concave mold is realized specifically by using a composite concave mold, and the composite concave mold includes an outer layer and an insulating layer arranged on the inner wall surface of the outer layer. The outer layer of the composite die is a metal outer layer, and the insulating layer material is made of insulating ceramics, of which the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com