Preparation method for mixed powder of graphene and titanium alloy

A technology for mixing powder and titanium alloy, applied in the field of powder titanium alloy material, can solve the problems of easy agglomeration of graphene nanosheets, difficulty in uniform mixing of graphene and titanium alloy, etc., achieves simple operation method, optimizes interface characteristics, and avoids over-temperature The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method comprises the following steps:

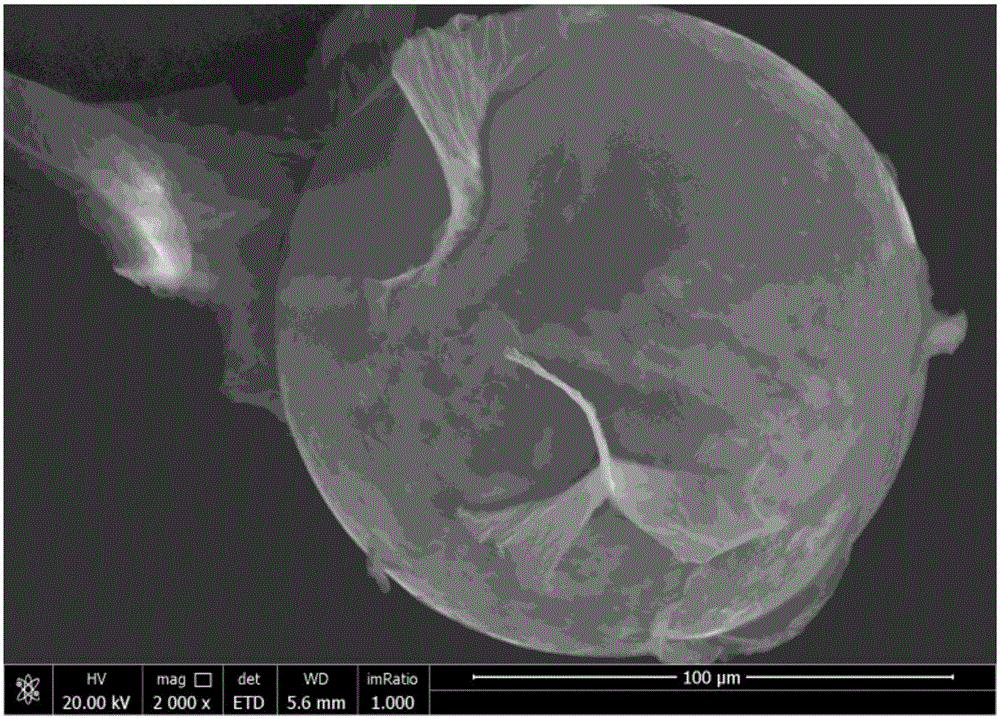

[0025] (1) Put the Φ(45-150)mm titanium alloy ingot or rod into the argon atomization powder making equipment, turn on the argon atomization powder making equipment to prepare spherical titanium alloy powder, and then transfer to the ultrasonic vibrating screen In the analyzer, after 2 to 3 times of vibrating sieving, the spherical titanium alloy powder with a particle size of 30 μm to 150 μm and an oxygen content of less than 1000 ppm is obtained.

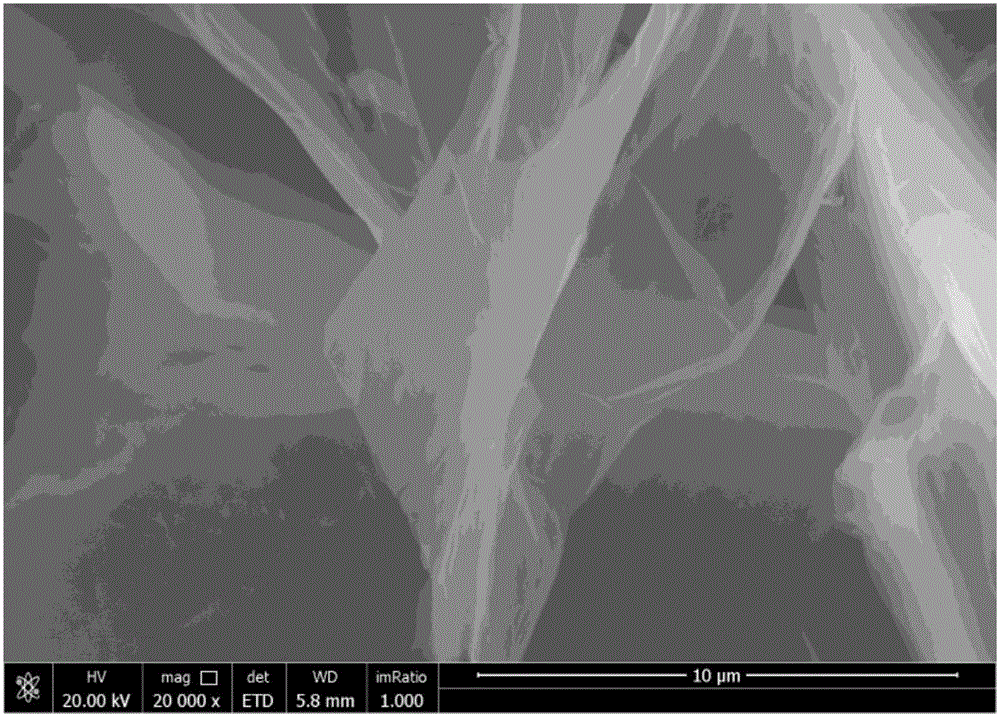

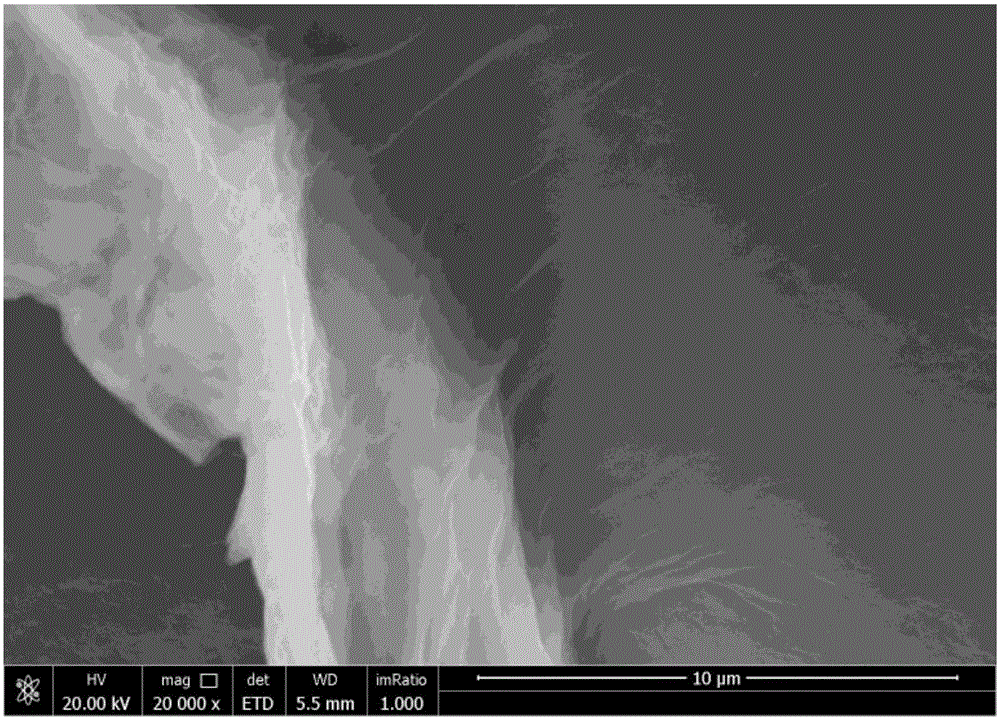

[0026] (2) Graphene nanosheets were prepared by the redox method. Under the field emission scanning electron microscope, the graphene nanosheets were feathery and translucent, with typical wrinkled structure characteristics, such as figure 1 shown; then, accurately weigh 0.1-10% of the titanium alloy powder mass graphene nanosheets and add to the beaker filled with absolute ethanol, the electronic balance accuracy is 0.01g.

[0027] (3) Turn on the high-speed dispersi...

Embodiment 1

[0037] (1) Prepare 1# titanium alloy powder by using plasma rotating electrode atomization powder making equipment, and then sieve the prepared powder twice to obtain 750 g of 1# titanium alloy powder with a particle size of 100-150 μm;

[0038] (2) Add 3g of graphene nanosheets prepared by the redox method to 100ml-500ml of absolute ethanol, and use a high-speed disperser to stir and mix. The graphene solution is prepared by the cell pulverizer. The working time of the ultrasonic cell pulverizer is 40 minutes, and the working frequency is 2 seconds of vibration and 3 seconds of gap;

[0039] (3) Transfer the 1# titanium alloy powder obtained in step (1) and the graphene solution prepared in step (2) to the 500ml specification batching tank of the temperature-controlled mechanical stirring device, and after sealing, open the temperature-controlled mechanical stirring device for uniform Mix to prepare graphene and 1# titanium alloy mixed powder slurry, the stirring speed is 500...

Embodiment 2

[0042] (1) 2# titanium alloy powder was prepared by argon atomization powder making equipment, and the prepared powder was sieved twice to obtain 600 g of 2# titanium alloy powder with a particle size of 50 μm to 100 μm;

[0043] (2) Add 2g of graphene nanosheets prepared by the redox method to 100ml-500ml of absolute ethanol, and use a high-speed dispersing agitator for stirring and mixing treatment. The graphene solution is prepared by the cell pulverizer. The working time of the ultrasonic cell pulverizer is 40 minutes, and the working frequency is 2 seconds of vibration and 3 seconds of gap;

[0044] (3) Transfer the 2# titanium alloy powder obtained in step (1) and the graphene solution prepared in step (2) to the 500ml specification batching tank of the temperature-controlled mechanical stirring device respectively, and after sealing, open the temperature-controlled mechanical stirring device for uniform Mix to prepare graphene and 2# titanium alloy mixed powder slurry, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com