A pressing process for preventing nodularizing agent from sticking to the package

A technology of nodularizing agent and sticking bag, which is used in manufacturing tools, metal processing equipment, casting melt containers, etc. effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

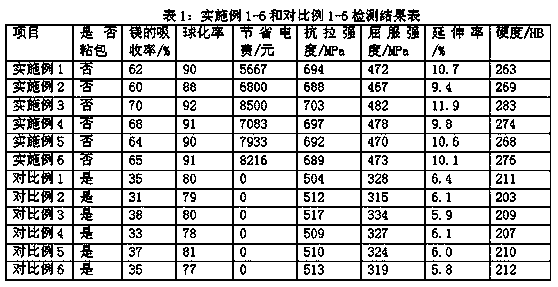

Examples

Embodiment 1

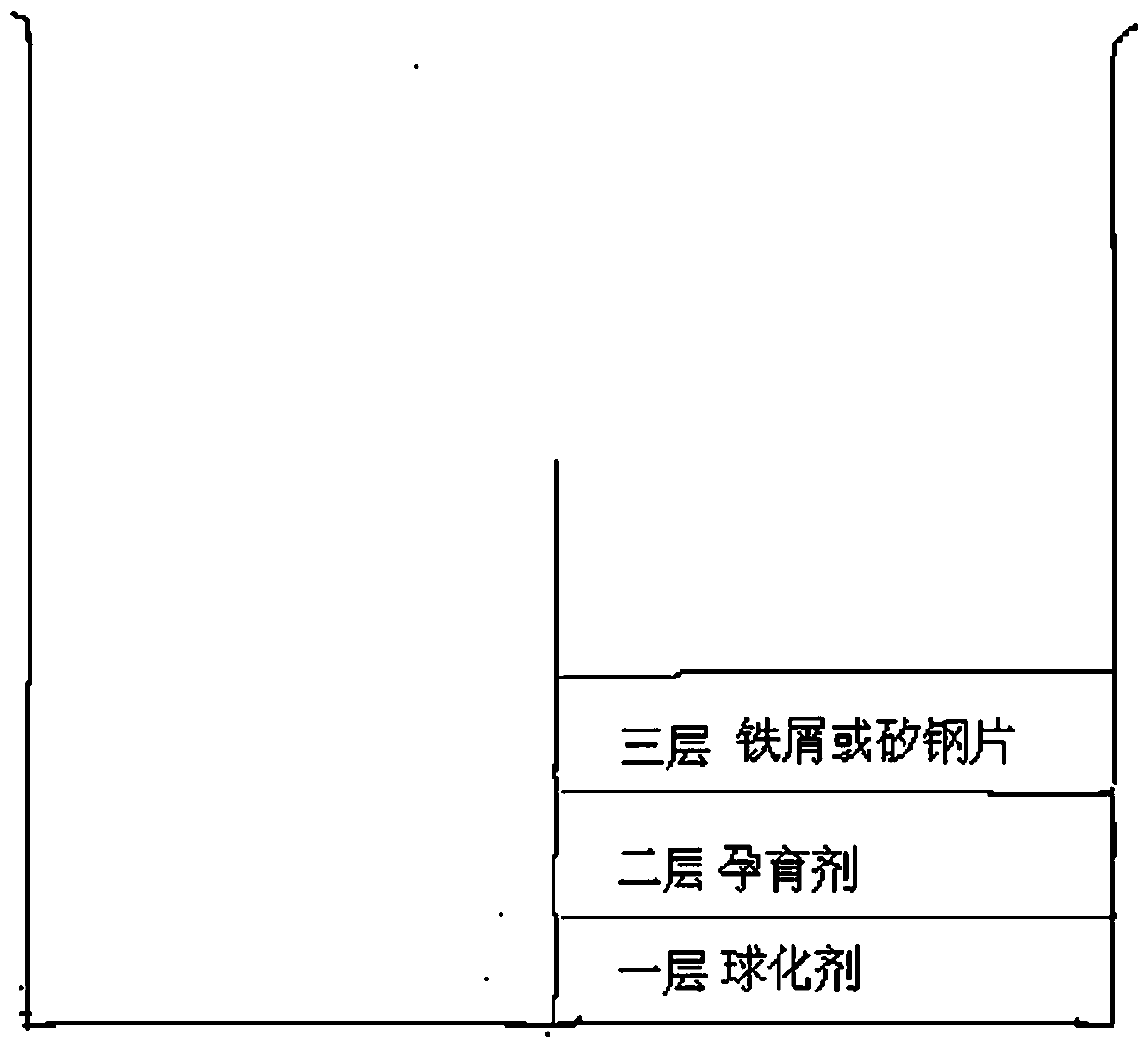

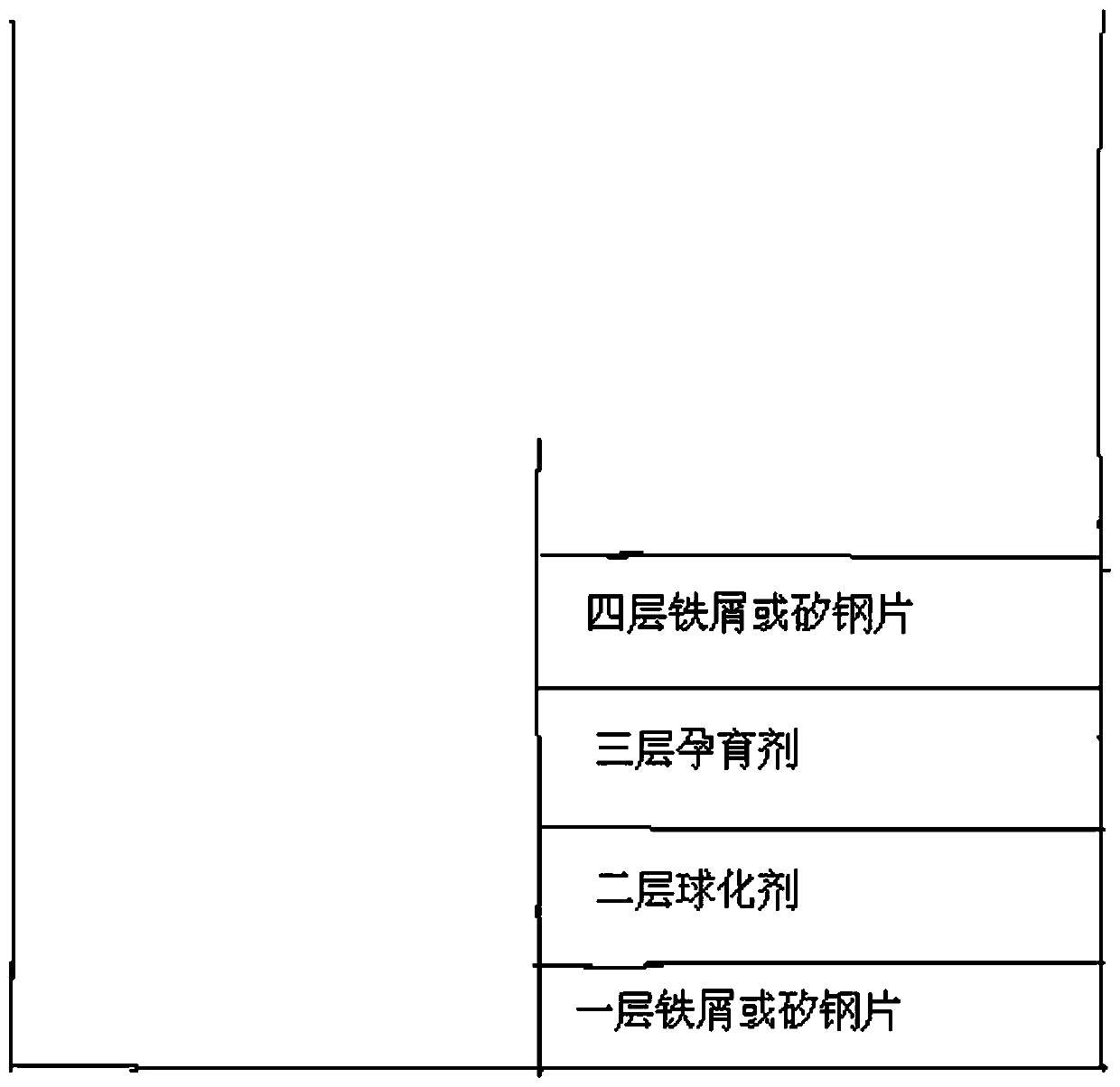

[0025] like figure 2 Shown, a kind of pressing bag process that prevents nodularizing agent sticking bag, comprises the following steps:

[0026] (1) Evenly lay iron filings or silicon steel sheets in the pit on one side of the dike-type casting bag as a layer, spread it flat, and hammer it firmly;

[0027] (2) Spread the nodulizer evenly on the first layer as the second layer, spread it flat, and hammer it firmly;

[0028] (3) Spread the inoculant evenly on the second layer as the third layer, flatten and hammer it;

[0029] (4) Evenly lay iron filings or silicon steel sheets on the three layers as four layers, spread them flat, and hammer them firmly. The thickness of the first layer is 20mm, the thickness of the second layer is 90mm, the thickness of the third layer is 50mm and the thickness of the fourth layer is 30mm .

[0030] Wherein, the embankment height of the embankment-type pouring ladle is 200mm; the ratio of the height to the diameter of the embankment-type p...

Embodiment 2

[0035] like figure 2 Shown, a kind of pressing bag process that prevents nodularizing agent sticking bag, comprises the following steps:

[0036] (1) Evenly lay iron filings or silicon steel sheets in the pit on one side of the dike-type casting bag as a layer, spread it flat, and hammer it firmly;

[0037] (2) Spread the nodulizer evenly on the first layer as the second layer, spread it flat, and hammer it firmly;

[0038] (3) Spread the inoculant evenly on the second layer as the third layer, flatten and hammer it;

[0039] (4) Evenly lay iron filings or silicon steel sheets on the third layer as four layers, flatten and hammer, and the thickness of the first layer is 30mm, the thickness of the second layer is 140mm, the thickness of the third layer is 90mm and the thickness of the fourth layer is 20mm .

[0040] Wherein, the embankment height of the embankment-type pouring ladle is 280 mm; the ratio of the height to the diameter of the embankment-type pouring ladle is 1...

Embodiment 3

[0045] like figure 2 Shown, a kind of pressing bag process that prevents nodularizing agent sticking bag, comprises the following steps:

[0046] (1) Evenly lay iron filings or silicon steel sheets in the pit on one side of the dike-type casting bag as a layer, spread it flat, and hammer it firmly;

[0047] (2) Spread the nodulizer evenly on the first layer as the second layer, spread it flat, and hammer it firmly;

[0048] (3) Spread the inoculant evenly on the second layer as the third layer, flatten and hammer it;

[0049] (4) Evenly lay iron filings or silicon steel sheets on the third layer as four layers, flatten and hammer, and the thickness of the first layer is 20mm, the thickness of the second layer is 110mm, the thickness of the third layer is 80mm and the thickness of the fourth layer is 20mm .

[0050] Wherein, the embankment height of the embankment-type pouring ladle is 240 mm; the ratio of the height to the diameter of the embankment-type pouring ladle is 2:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com