Method and device for desulfurizing and denitrating flue gas based on cryogenic liquefaction and separation

A technology of liquefaction separation, desulfurization and denitrification, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as high energy consumption, large investment, and secondary pollution, and achieve low energy consumption, small equipment volume, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

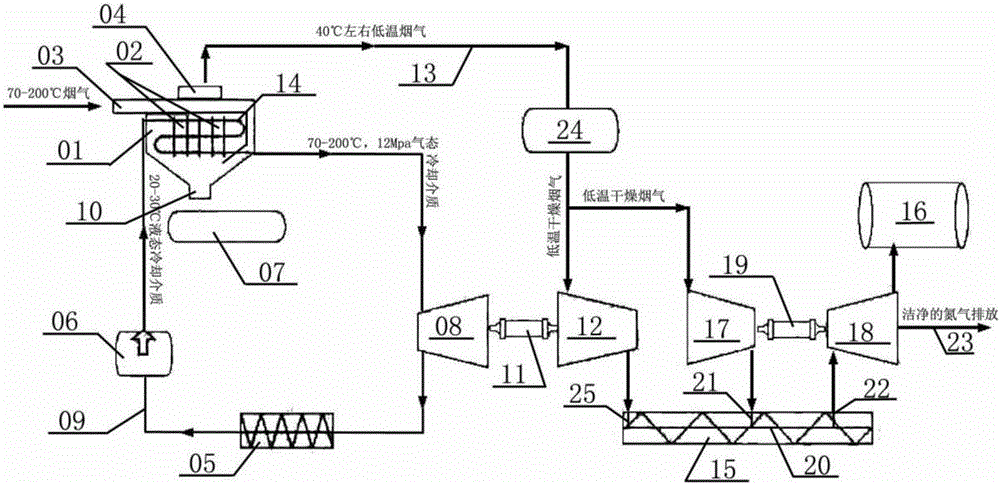

[0022] refer to figure 1 , The flue gas desulfurization and denitrification device based on cryogenic liquefaction separation disclosed in this embodiment includes: a flue gas waste heat boiler 01, a flue gas waste heat recovery system and a flue gas separation system.

[0023] A plurality of condensation pipes 02 are arranged vertically inside the flue gas waste heat boiler 01. The upper part and the upper side of the flue gas waste heat boiler are respectively provided with an air inlet 03 and an air outlet 04. The air inlet 03 and the air outlet of the flue gas waste heat boiler 01 are 04 communicates with the lower end and the upper end of a plurality of condensation pipes 02 respectively.

[0024] The flue gas waste heat recovery system includes an air cooler 05 , a working medium pump 06 , a flue gas condensed water collector 07 and a waste heat expander 08 . The air cooler 05 and the working medium pump 06 are installed on the medium circulation pipe 09 located outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com