A food mixing and unloading mechanism

A stirring motor, food technology, applied in food forming, food science, loading/unloading, etc., can solve the problems of low efficiency, trouble, poor effect, etc., achieve the effect of realizing the rotation angle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

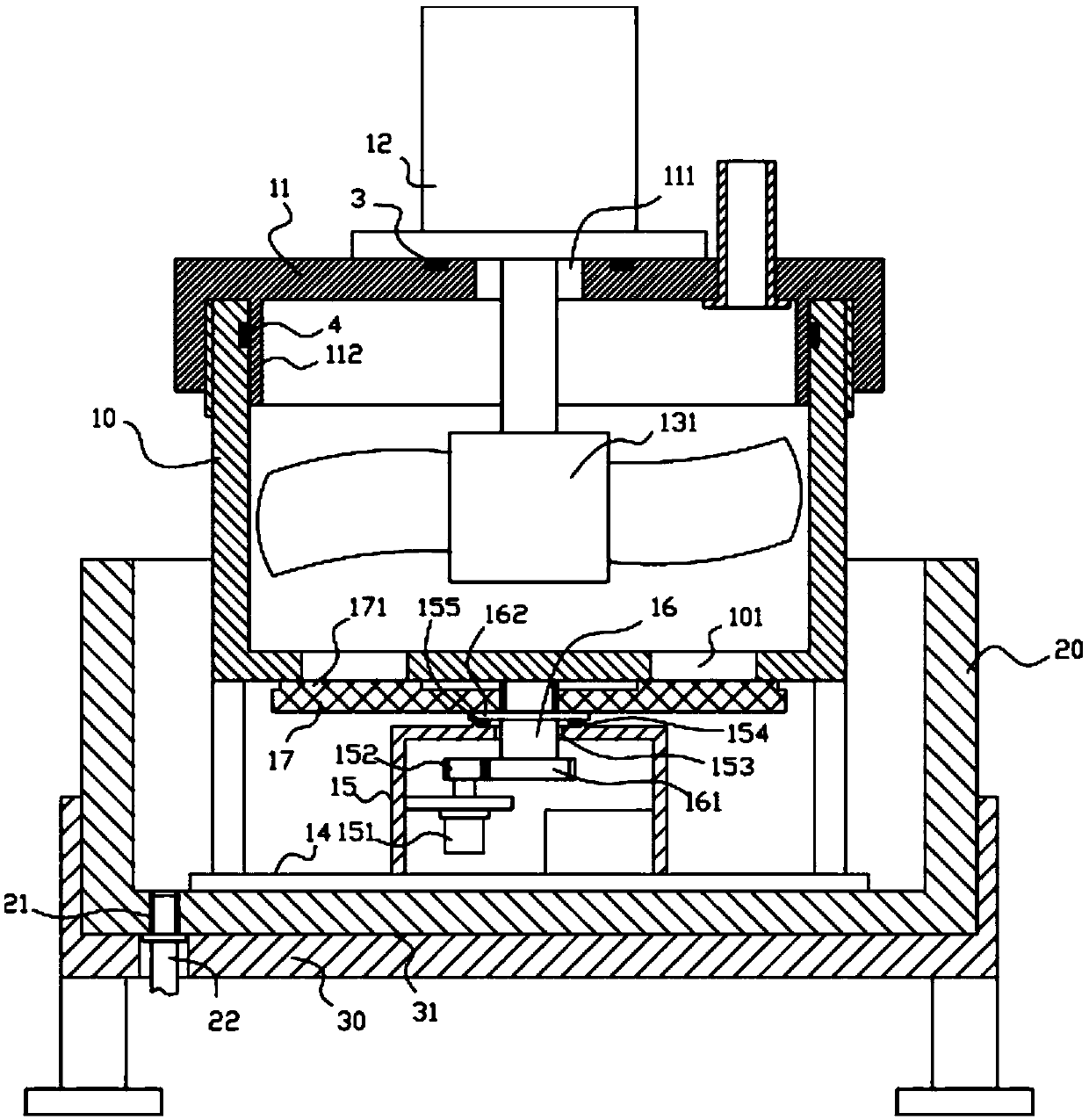

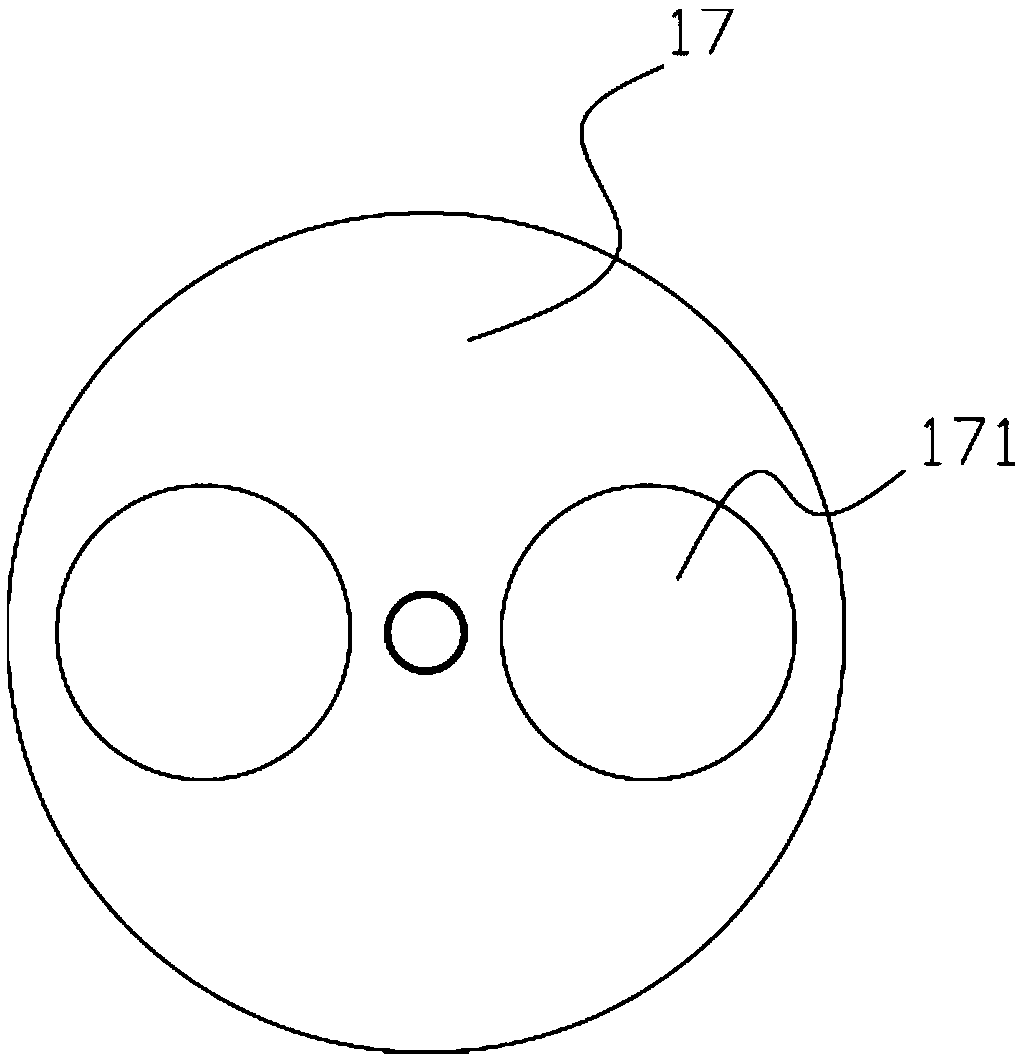

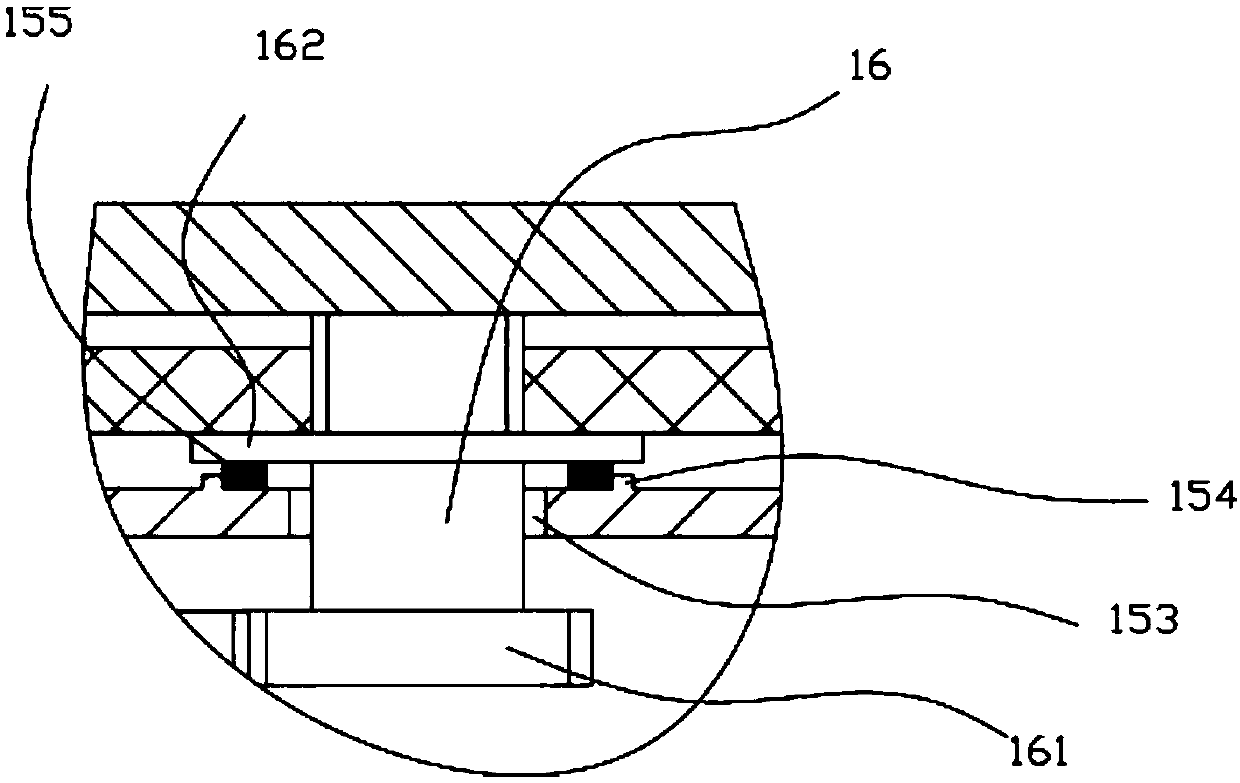

[0015] Example: see Figure 1 to Figure 3 As shown, a kind of food stirring and unloading mechanism comprises a mixing barrel body 10, a stirring cover 11 is fixed on the top of the stirring barrel body 10, a stirring motor 12 is fixed on the top surface of the stirring cover 11, and the output shaft of the stirring motor 12 is Pass through the middle through hole 111 of the stirring cover 11 and be fixed with the stirring impeller 131. The receiving barrel body 20 is below the stirring barrel body 10. The bottom support frame 14 is fixed on the bottom of the stirring barrel body 10. The bottom plate of the bottom support frame 14 Press against the top surface of the bottom plate of the material receiving barrel body 20, the bottom plate of the bottom support frame 14 is fixed with a drive box 15, the inner side wall of the drive box 15 is fixed with an adjustment motor 151, and the output shaft of the adjustment motor 151 Adjustment gear 152 is fixed, and the middle bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com