Welding-free high-frequency high-sound-pressure buzzer and production method

A welding-free, buzzer technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of narrow frequency band and low sound pressure, and achieve the effect of avoiding welding process, simplifying production process, and overcoming cumbersome installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

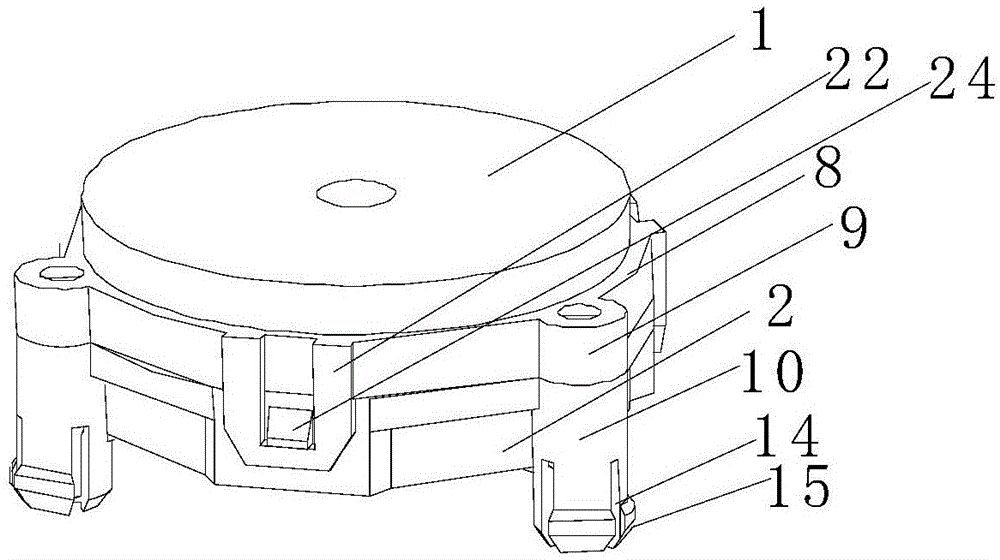

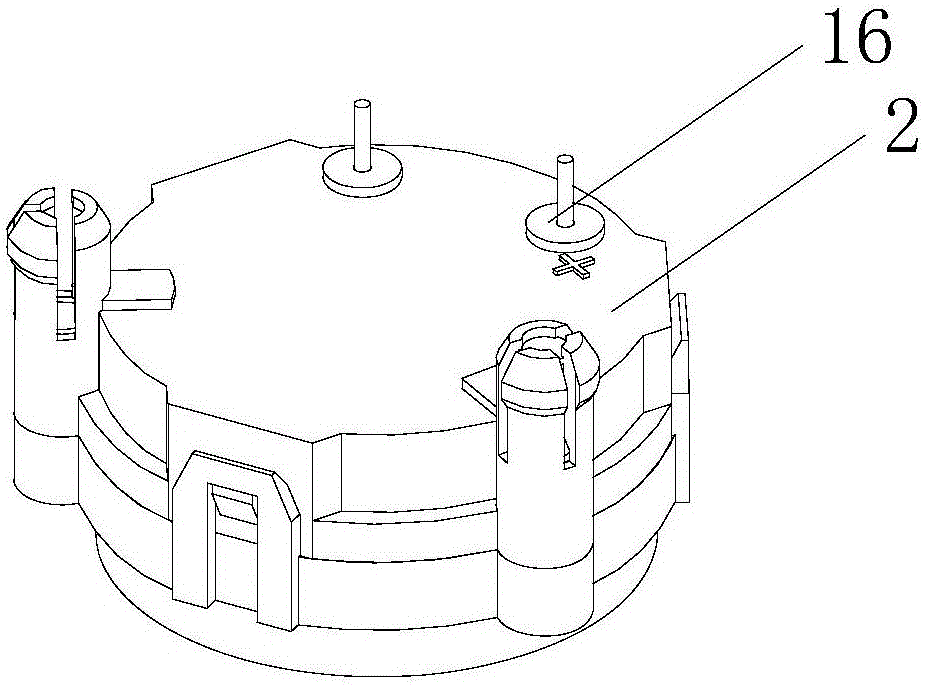

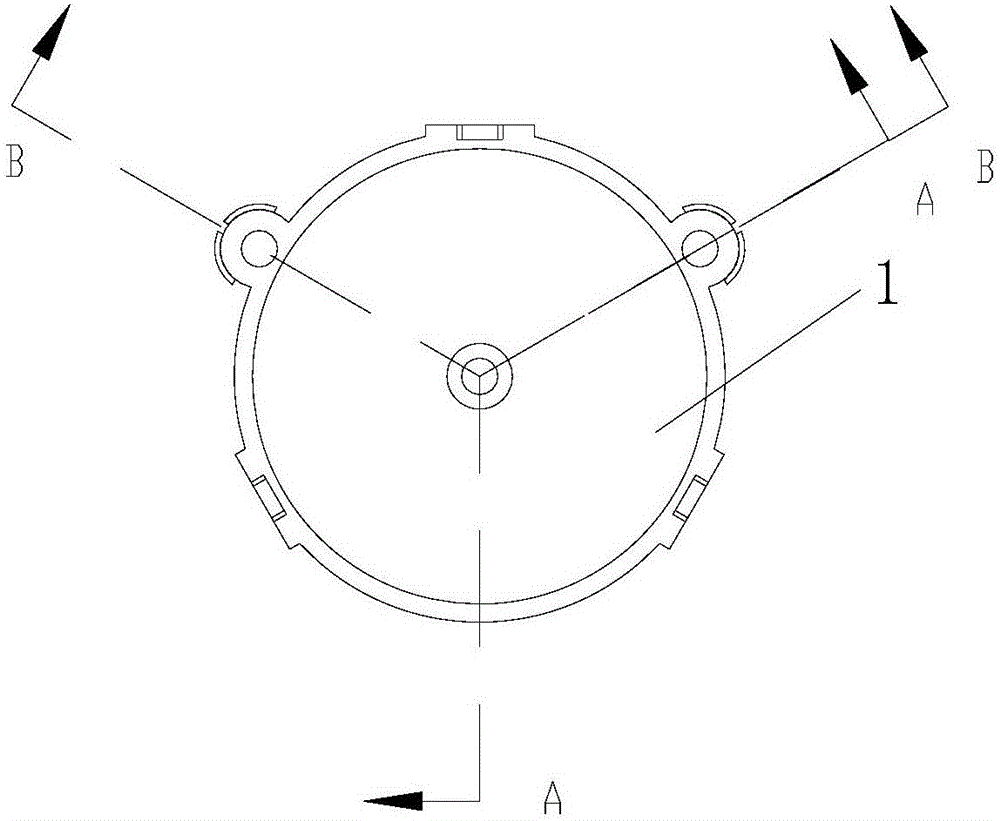

[0042] see figure 1 As shown, a welding-free high-frequency high-sound pressure buzzer includes an upper shell 1 and a lower shell 2, the upper shell and the lower shell are detachably connected, and the cavity formed by the upper and lower shells is from A mass sheet 3, a diaphragm sheet 4, a magnetic ring 5, a coil 6 provided with an iron core, and a circuit board 7 are sequentially provided from top to bottom; it is characterized in that a step portion 8 is provided on the outer surface of the upper casing; There are at least two upper inserts 9 on the outer surface of the step part, and a lower insert 10 that can be plugged with the upper inserts on the outer surface of the lower housing; the upper and lower inserts are respectively provided with upper sockets 11 and lower Jack 12, the upper and lower jacks are connected, and the upper and lower jacks are provided with a plug 13 that can move in the upper and lower jacks; the lower side of the lower insert is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com