Rotary dryer suitable for garbage materials

A dryer and material technology, applied in dryers, garbage drying, drying and other directions, can solve the problems of easy shrinkage and deformation of garbage, bulky overall structure, and difficulty in hot air flow and temperature, so as to avoid being blown by hot air. The effect of walking, improving heat transfer efficiency and improving material copying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

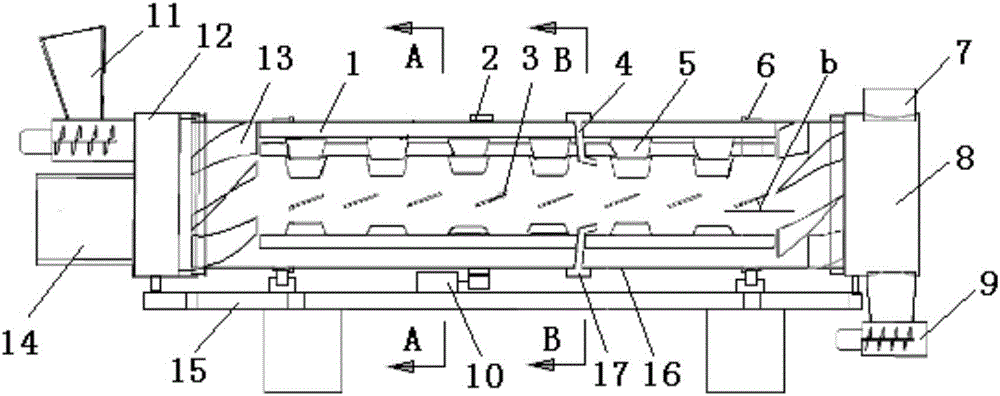

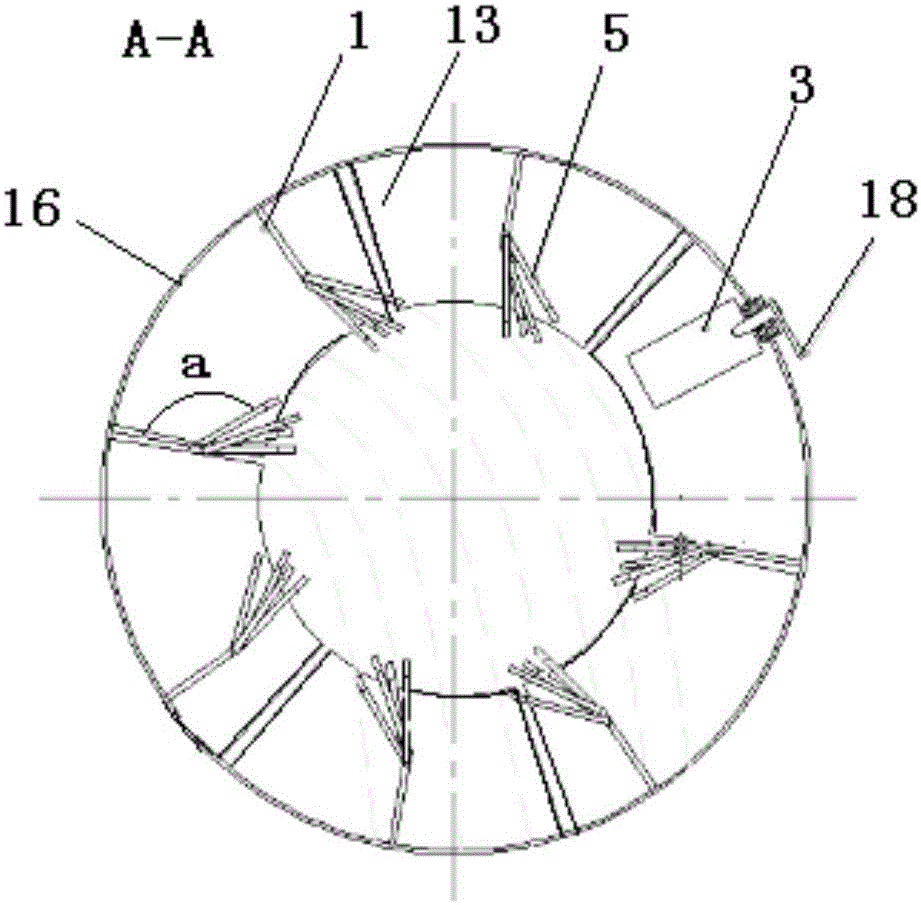

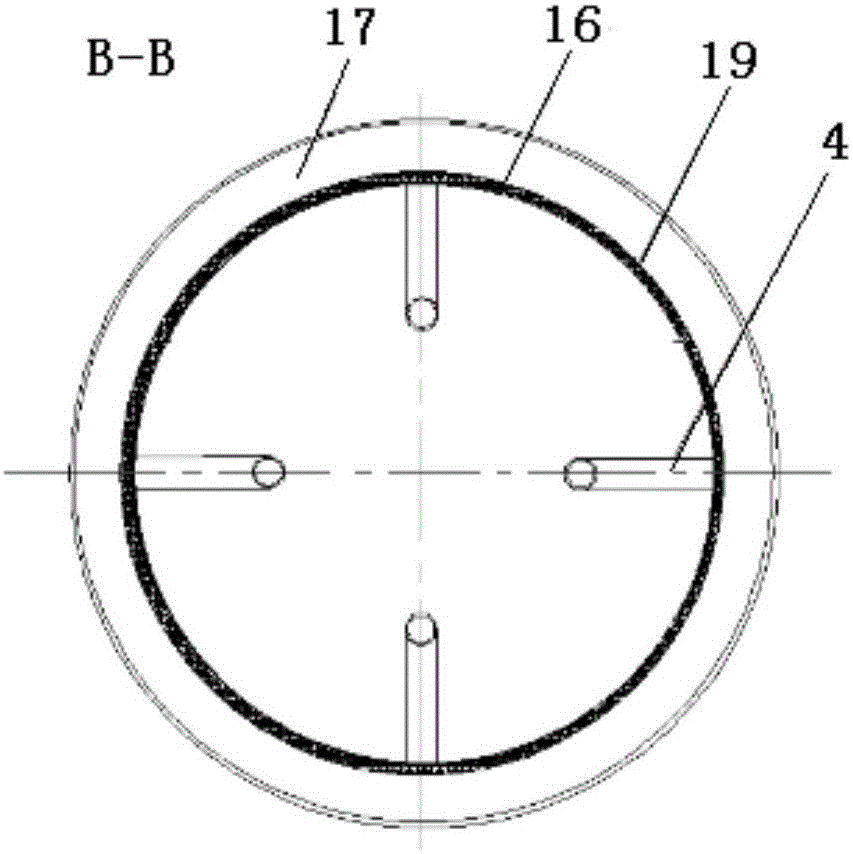

[0021] see Figure 1 ~ Figure 3 , a new type of rotary drum dryer suitable for garbage materials of the present invention includes a cylinder body 16, a cylinder body driving device (the drive motor 10 meshes with the gear ring 2 provided on the cylinder body through the gear of its output shaft), Material inlet assembly (including feed inlet 11, feed end cylinder 12, deflector 13, flue gas inlet 14) and material outlet assembly (air induction port 7, outlet end cylinder 8, discharge port 9), cylinder 16 passes through The support mechanism (supporting ring and idler roller 6) is rotatably supported on the base 15, and the cylinder 16 is in transmission connection with the cylinder driving device, and the drive motor 10 rotates with the cylinder through the drive gear ring 2. The material inlet assembly and the material outlet assembly are respectively installed at both ends of the barrel. The above structures are conventional technologies. Wherein, the cylinder body 16 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com