System and method for waste pyrolysis, gasification and fusion

A technology of pyrolysis gasification and gasification melting, which is applied in the field of garbage pyrolysis gasification melting system, can solve the problems of difficult to realize industrial application, increase of operating cost, complicated oil-water separation and purification equipment, etc., and achieve the benefit of industrialization and Large-scale application, high waste heat recovery and utilization rate, and good product economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

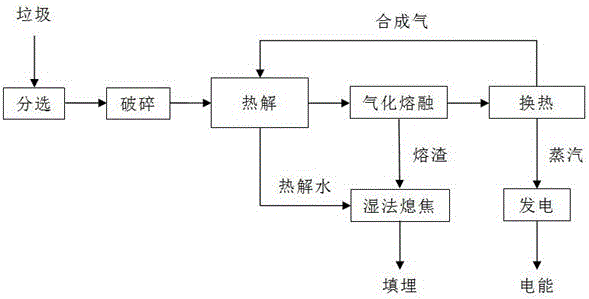

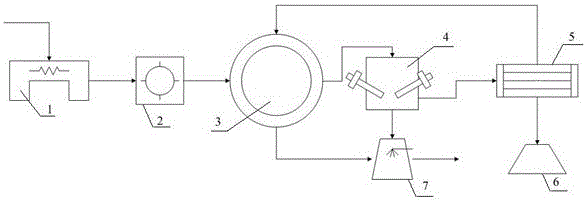

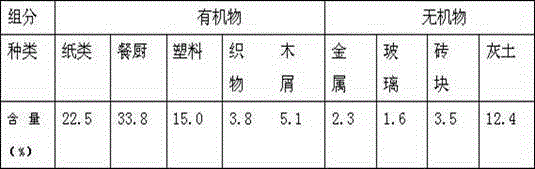

[0034] Use the waste pyrolysis gasification melting system to process the waste in a community. The moisture content of the waste is 38%, and the percentage content of each component is shown in Table 1. Among them, the structural diagram of the waste pyrolysis gasification melting is as follows figure 2 As mentioned, the process flow is as figure 1 As shown, the specific processing flow is as follows:

[0035] Table 1 Percentage of each component of garbage (wet basis)

[0036]

[0037] The garbage with a moisture content of 38% is sent to the sorting device to remove inorganic substances such as glass and metal, and then enters the crushing equipment to obtain garbage raw materials with a particle size of less than 90mm. The waste material is sent to the regenerative rotary bed, the temperature of the regenerative radiant tube in the drying zone is 500°C, and the temperature of the regenerative radiant tube in the pyrolysis zone is 900°C. Garbage in the rotary bed unde...

Embodiment 2

[0040] Use the garbage pyrolysis gasification melting system to process the garbage in a certain city. The moisture content of the garbage is 40%, and the percentage content of each component is shown in Table 2. Among them, the structural diagram of the garbage pyrolysis gasification melting system Such as figure 2 As mentioned, the process flow is as figure 1 As shown, the specific processing flow is as follows:

[0041] Table 2 Percentage of each component of garbage (wet basis)

[0042]

[0043] The garbage with a moisture content of 40% is sent to the sorting device to remove inorganic substances such as glass and metal, and then enters the crushing equipment to obtain garbage raw materials with a particle size of less than 100mm. The waste material is sent to the regenerative rotary bed, the temperature of the regenerative radiant tube in the drying zone is 600°C, and the temperature of the regenerative radiant tube in the pyrolysis zone is 1000°C. Garbage in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com