Blue light conversion tape and backlight module

A blue light and tape technology, applied in the field of tape, can solve the problems of quantum dots unstable to water vapor and oxygen, blue light shielding, weakened shielding, etc., to overcome the leakage of blue light, maintain color white balance, and improve chromaticity uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

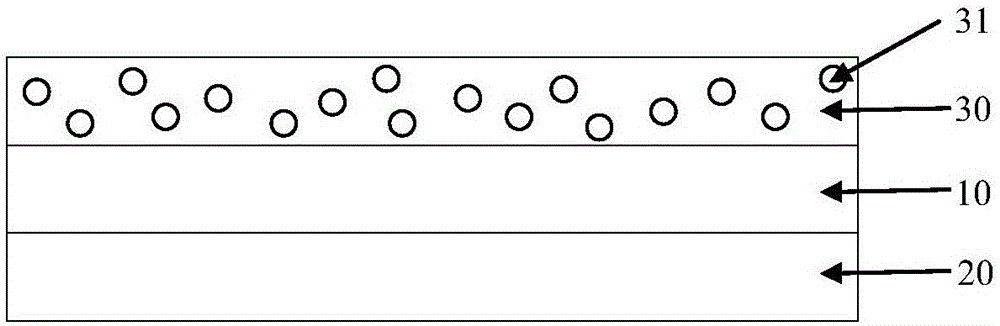

[0034]Mix 100g film-forming resin UVBC-001E (solid content 80%, manufactured by Kangdexin), 1g release agent BYK394 (manufactured by BYK), and 5g yellow phosphor powder (model BM304C, manufactured by Borui Optoelectronics) and perform high-speed shearing Cut and disperse to obtain a composite layer coating. Apply the above-mentioned composite layer coating on one side of the PET substrate with a wire bar coater, the coating thickness is 100 μm, and after UV curing, apply a commercially available adhesive on the other side of the PET substrate to form a blue light conversion adhesive tape.

[0035] The module with the blue LED light as the backlight is tested, and the blue light conversion tape is pasted on the light leakage surface of the light guide plate to test the color coordinates of the output light of the module.

Embodiment 2

[0037] 93g thermosetting film-forming resin DBD01A (manufactured by Kangdexin), 7g thermosetting film-forming resin DHD01A (manufactured by Kangdexin), 20g release agent BYK394 (manufactured by BYK), 46g green phosphor (model GM537, Borui Optoelectronics) Manufacturing), 4g of red phosphor (model RRH630, manufactured by Borui Optoelectronics) were mixed evenly for high-speed shear dispersion to obtain a composite layer coating. The above-mentioned composite layer coating is coated on one side of the PET substrate with a wire bar coater, and the coating thickness is 10 μm. After thermal curing in an oven, a commercially available adhesive is coated on the other side of the PET substrate to form Blu-ray conversion tape.

[0038] The module with the blue LED light as the backlight is tested, and the blue light conversion tape is pasted on the light leakage surface of the light guide plate to test the color coordinates of the output light of the module.

Embodiment 3

[0040] 100g film-forming resin UVBC-001E (solid content 80%, manufactured by KDX), 20g release agent BYK394 (manufactured by BYK), 20g yellow phosphor (model BM304C, manufactured by Borui Optoelectronics), 55.2g green phosphor ( Model GM537, manufactured by Borui Optoelectronics), 4.8g of red phosphor powder (model RRH630, manufactured by Borui Optoelectronics) were mixed uniformly for high-speed shear dispersion to obtain a composite coating. Apply the above-mentioned composite layer coating on one side of the PET substrate with a wire bar coater, the coating thickness is 7 μm, and after UV curing, apply a commercially available adhesive on the other side of the PET substrate to form a blue light conversion adhesive tape.

[0041] The module with the blue LED light as the backlight is tested, and the blue light conversion tape is pasted on the light leakage surface of the light guide plate to test the color coordinates of the output light of the module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com