A preparation method of stable peelable ultra-thin carrier copper foil

A carrier copper foil and carrier foil technology, applied in the field of copper foil manufacturing, can solve the problems of uneven adsorption, difficult peeling, poor conductivity, etc., and achieve the effects of simple operation, good conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

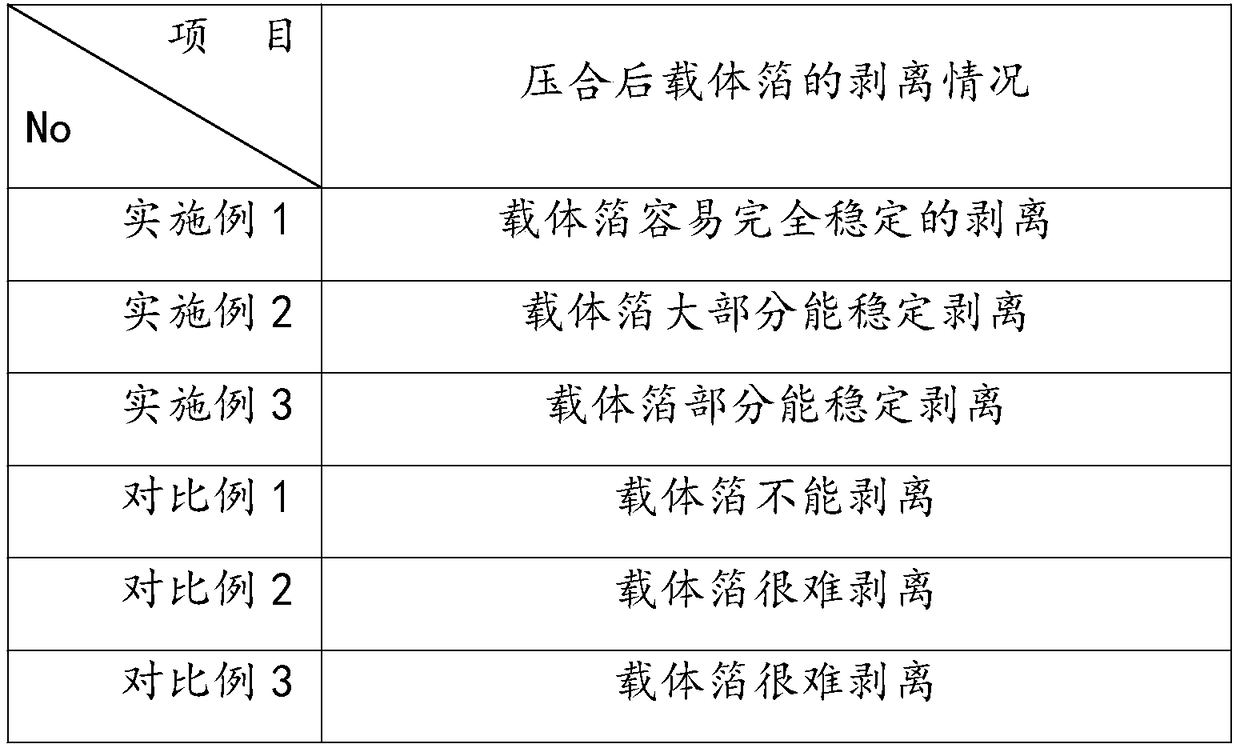

Examples

Embodiment 1

[0019] A preparation method of ultra-thin carrier copper foil, comprising the steps of:

[0020] 1) Plating solution preparation: dissolving the complexing agent potassium pyrophosphate, zinc sulfate, additive A and additive B in water respectively, and mixing them after clarification to obtain a plating solution, wherein the additive A is made of Co(NO 3 ) 2 6H 2 O and Fe(NO 3 ) 3 9H 2 O is a mixture formed at a mass ratio of 9:1, additive B is a mixture formed of oxalic acid and sodium thiosulfate at a mass ratio of 4:6, the content of complexing agent potassium pyrophosphate in the plating solution is 80g / L, sulfuric acid The content of zinc is 14g / L, the content of additive A is 10g / L, and the content of additive B is 8g / L;

[0021] 2) Electroplating: The carrier foil is placed in the above-mentioned plating solution as the cathode, and under the action of direct current, a layer of nano-scale composite galvanized layer is electroplated on the carrier foil as a peelin...

Embodiment 2

[0024] A preparation method of ultra-thin carrier copper foil, comprising the steps of:

[0025] 1) Plating solution preparation: dissolving the complexing agent potassium pyrophosphate, zinc sulfate, additive A and additive B in water respectively, and mixing them after clarification to obtain a plating solution, wherein the additive A is made of Co(NO 3 ) 2 6H 2 O and Ti(NO 3 ) 4 The mixture formed at a mass ratio of 7:3, the additive B is a mixture formed of formic acid and sodium hypophosphite at a mass ratio of 4:6, the content of complexing agent potassium pyrophosphate in the plating solution is 100g / L, and the content of zinc sulfate The content of additive A is 20g / L, the content of additive A is 6g / L, and the content of additive B is 10g / L;

[0026] 2) Electroplating: The carrier foil is placed in the above-mentioned plating solution as the cathode, and under the action of direct current, a layer of nano-scale composite galvanized layer is electroplated on the ca...

Embodiment 3

[0029] A preparation method of ultra-thin carrier copper foil, comprising the steps of:

[0030] 1) Plating solution preparation: dissolving the complexing agent potassium pyrophosphate, zinc sulfate, additive A and additive B in water respectively, and mixing them after clarification to obtain a plating solution, wherein the additive A is made of Mn(NO 3 ) 2 with Al(NO 3 ) 3 A mixture formed at a mass ratio of 9:1, additive B is a mixture formed of oxalic acid and ammonium chloride at a mass ratio of 4:6, the content of complexing agent potassium pyrophosphate in the plating solution is 40g / L, and the content of zinc sulfate The content is 10g / L, the content of additive A is 5g / L, and the content of additive B is 5g / L;

[0031] 2) Electroplating: The carrier foil is placed in the above-mentioned plating solution as the cathode, and under the action of direct current, a layer of nano-scale composite galvanized layer is electroplated on the carrier foil as a peeling layer, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com