Method for preparing oxidized graphene

A technology of graphene and graphite, which is applied in the field of improving the preparation method of graphene oxide, can solve problems such as easy damage to graphene oxide sheet structure, temperature rise of graphite oxide solution, uneven size of graphene oxide, etc., to achieve favorable Environmental protection, easy mass production, complete stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention will be described in further detail below. A kind of preparation method of graphene oxide is characterized in that, the step of preparation is:

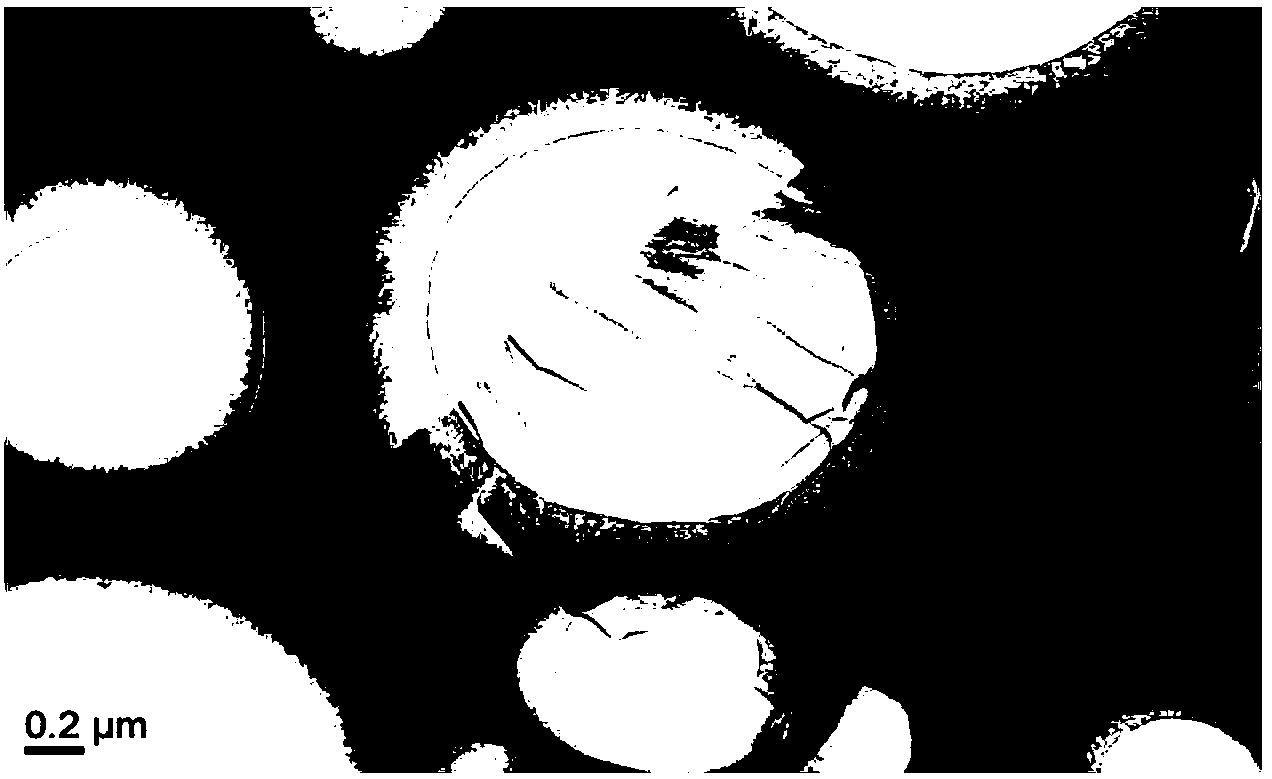

[0017] 1. Preparation of graphite oxide: oxidized intercalation of flake graphite or highly oriented pyrolytic graphite by Hummers method or Staudenmaier method to obtain graphite oxide; the layer spacing of graphite oxide sheets is 0.6nm-1.0nm;

[0018] 2. Preparation of graphite oxide aqueous solution: dissolve dry graphite oxide powder in deionized water, stir for 20-60 minutes to prepare graphite oxide aqueous solution, the concentration is 0.1mg / mL-10mg / mL;

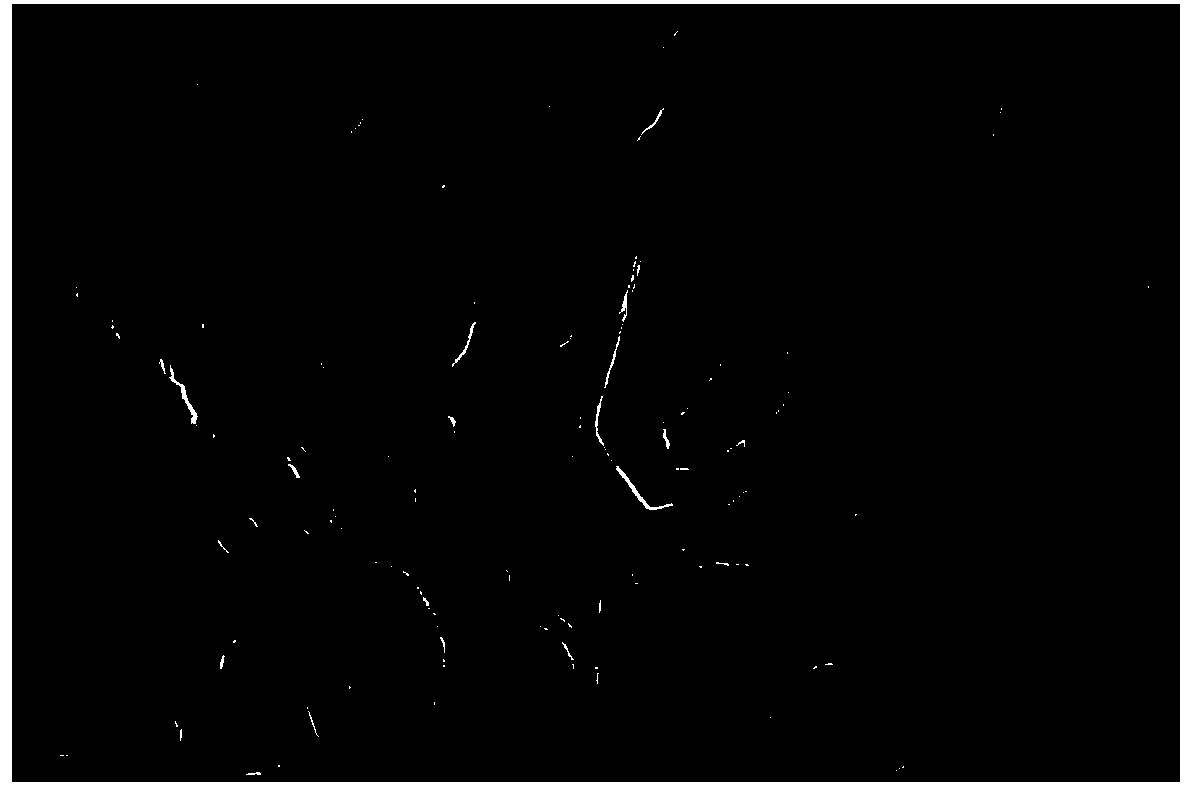

[0019] 3. Freezing: Put not less than 10ml of graphite oxide aqueous solution in a cold storage not higher than 0°C for not less than 60 minutes to make it completely freeze, and use the hydrogen bond formed when water freezes to cause the volume to increase. Expansion principle exfoliates graphite oxide;

[0020] 4. Thawing: After taking out ...

Embodiment 1

[0025] Using the Hummers method, add 100mL of 98% concentrated sulfuric acid into a dry single-necked flask, cool it to 0°C with a low-temperature coolant circulation pump, add 4g of natural flake graphite, 2g of NaNO 3 and 12g KMnO 4 , control the temperature of the reaction solution at 10-15°C, stir and react for 2 hours; then place the beaker in a constant temperature water bath at about 35°C, and continue stirring for 30 minutes when the temperature of the reaction solution rises to about 35°C; finally add 200mL deionized water, control the temperature of the reaction solution within 100°C, and continue to stir for 2h. Dilute the reaction solution to 800-1000mL with deionized water, then add 100mL of 5% H2O2, filter while hot, wash fully with 5% HCI and deionized water until there is no sulfate ion in the filtrate (detected with BaCl solution), and The filter cake was dried in a vacuum oven at 80°C for 12 hours to obtain dry graphite oxide flakes. The interlayer distance ...

Embodiment 2

[0028] Using the Staudenmaier method, add natural flake graphite to the mixture of 98% concentrated sulfuric acid and 65% concentrated nitric acid, wherein the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1, add sodium nitrate under magnetic stirring, and react at room temperature for 24h to obtain oxidized Graphite, dilute the reactant, wash with 5% dilute hydrochloric acid and deionized water until there is no SO in the filtrate 4 2- And it is neutral, and the graphite oxide powder is obtained after drying and grinding, and the interlayer distance of graphite oxide is 1.0nm.

[0029] Take 0.2g of graphite oxide and dissolve it in 50mL of deionized water (the concentration of graphite oxide is 4mg / mL), and magnetically stir for 40min to obtain a uniformly dispersed aqueous solution of graphite oxide. Then place it in a freezer at -5°C for 3 hours to completely freeze it, then melt it at room temperature, dry it in a vacuum oven at 80°C for 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com