Static barrier mixing device for semi-solid-state alloy pulp-making

A semi-solid and barrier technology, applied in the field of static barrier mixing devices for semi-solid alloy pulping, can solve the problems of no temperature control device, narrow temperature range, high equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

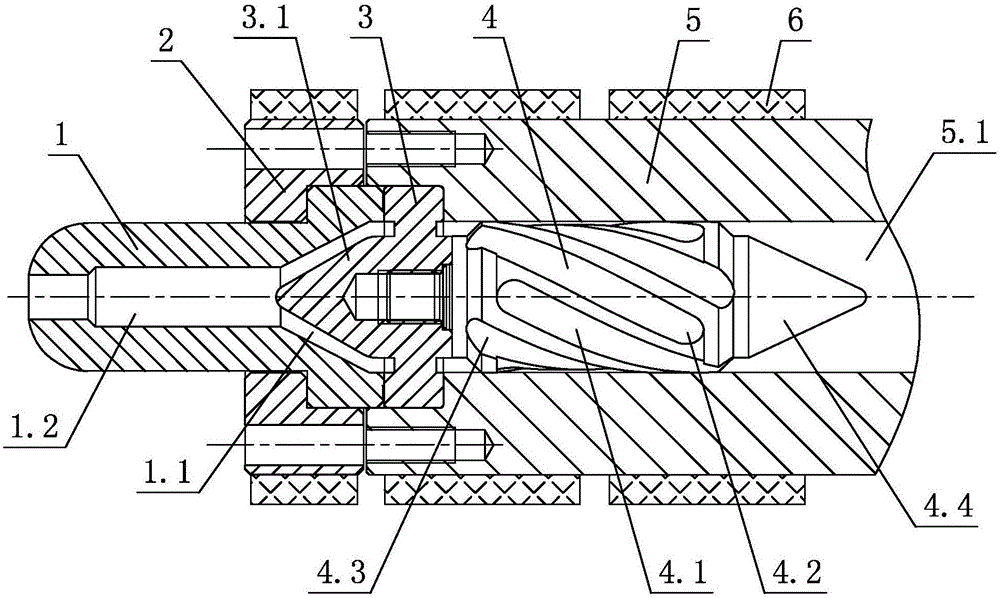

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

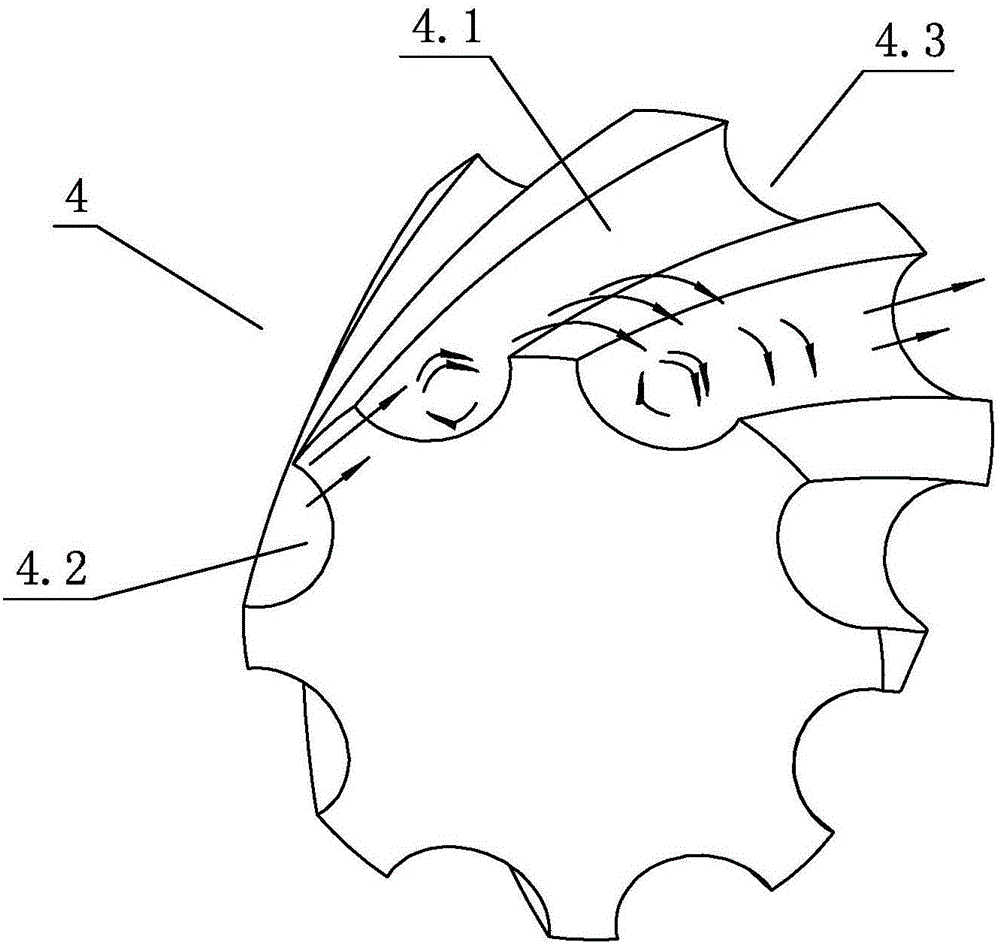

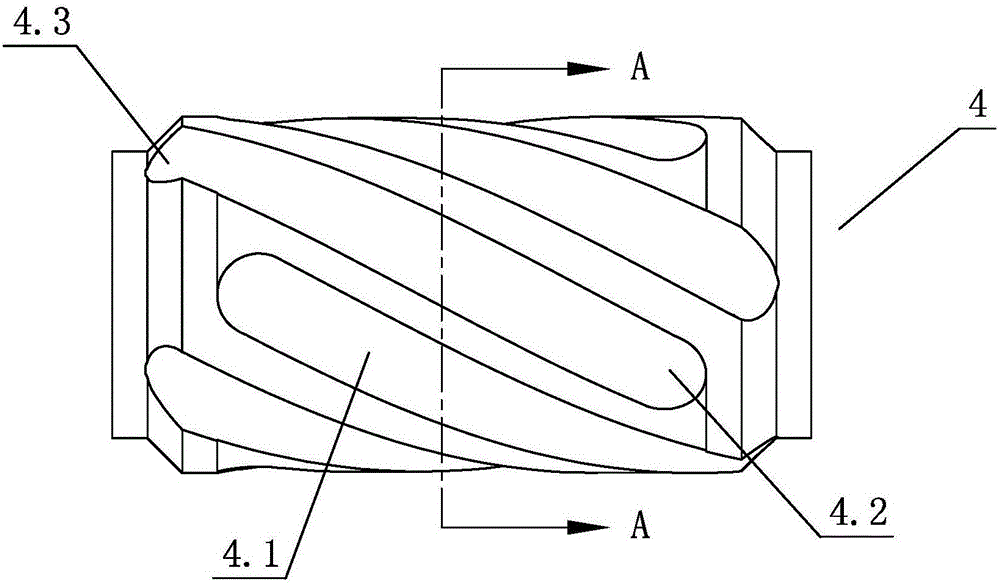

[0023] see Figure 1-Figure 4 , the static barrier mixing device for semi-solid alloy pulping, including a nozzle 1 and a barrel 5, the nozzle 1 is arranged on the barrel 5, a collecting comb plate 3 is arranged between the nozzle 1 and the barrel 5, and the barrel 5 A cavity 5.1 is arranged inside the cavity 5.1, and a barrier mixing head 4 is arranged inside the cavity 5.1. The barrier mixing head 4 is statically arranged in the cavity 5.1, and a plurality of chute 4.1 is spirally arranged on its outer wall.

[0024] Furthermore, the barrier mixing head 4 is cylindrical, the shape of the cavity 5.1 corresponds to the barrier mixing head 4, and the periphery of the barrier mixing head 4 and the inner wall of the cavity 5.1 statically cooperate with each other.

[0025] Furthermore, the outer wall of the barrier mixing head 4 is spirally provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com