A kind of lead plaster desulfurization method with ultrasonic strengthening ammonium bicarbonate as desulfurization agent

A technology of ammonium bicarbonate and ultrasonic waves, which is applied in the field of desulfurization of lead paste in the regeneration process of waste lead-acid batteries, can solve the problems of hindering the reaction and producing a large amount, and achieve the effects of eliminating foam, good desulfurization effect, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

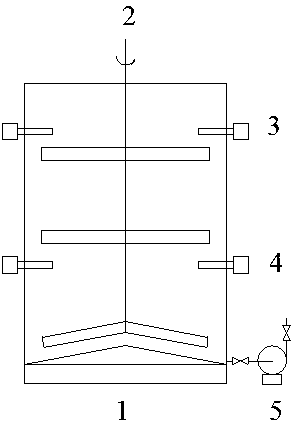

Image

Examples

Embodiment 1

[0018] Put 400 kg of lead paste obtained after crushing waste lead-acid batteries into a desulfurization tank, add 900 kg of water to make 1 m of slurry with a mass percentage of 30.8% 3 , start the stirrer, adjust the stirring speed to 80 rpm, stir for 5 minutes, weigh a total of 107 kg of desulfurizer NH 4 HCO 3 , start the ultrasonic generator, add NH in 3 times 4 HCO 3 , with an interval of 10 minutes, the successive additions are 50 kg, 40 kg, and 27 kg. The sulfur content of the original lead paste is 5.3%. After desulfurization by this desulfurization process for 40 minutes, the sulfur content of the lead paste after desulfurization is 0.32%.

Embodiment 2

[0020] Put 600 kg of lead paste obtained after crushing waste lead-acid batteries into a desulfurization tank, add 900 kg of water to make 1.2 m of slurry with a mass percentage of 40% 3 , start the stirrer, adjust the stirring speed to 100 rpm, stir for 5 minutes, weigh a total of 162 kg of desulfurizer NH 4 HCO 3 , start the ultrasonic generator, add NH in 3 times 4 HCO 3 , with an interval of 10 minutes, the successive additions are 80 kg, 60 kg, and 22 kg. The sulfur content of the original lead paste is 5.3%. After desulfurization by this desulfurization process for 40 minutes, the sulfur content of the lead paste after desulfurization is 0.34%.

Embodiment 3

[0022] Put 1200 kg of lead paste obtained after crushing waste lead-acid batteries into the desulfurization tank, add 900 kg of water to make 1.5m of slurry with a mass percentage of 57% 3 , start the stirrer, adjust the stirring speed to 120 rpm, stir for 5 minutes, weigh a total of 330 kg of desulfurizer NH 4 HCO 3 , start the ultrasonic generator, add NH in 4 times 4 HCO 3 , with an interval of 10 minutes, the successive additions are 400 kg, 300 kg, 300 kg, and 200 kg. The sulfur content of the original lead paste is 5.3%. After desulfurization by this desulfurization process for 60 minutes, the sulfur content of the lead paste after desulfurization is 0.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com