Upper sprinkling secondary refining gas purifying technology

A technology of gas purification and technology, which is applied in the direction of chemical instruments and methods, the use of liquid separation agents, and the separation of dispersed particles. It can solve the problems of short washing and absorption time, poor washing and absorption effects, and small spray holes, etc., to achieve increased washing. Improvement of absorption surface area, residence time, and reduction of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

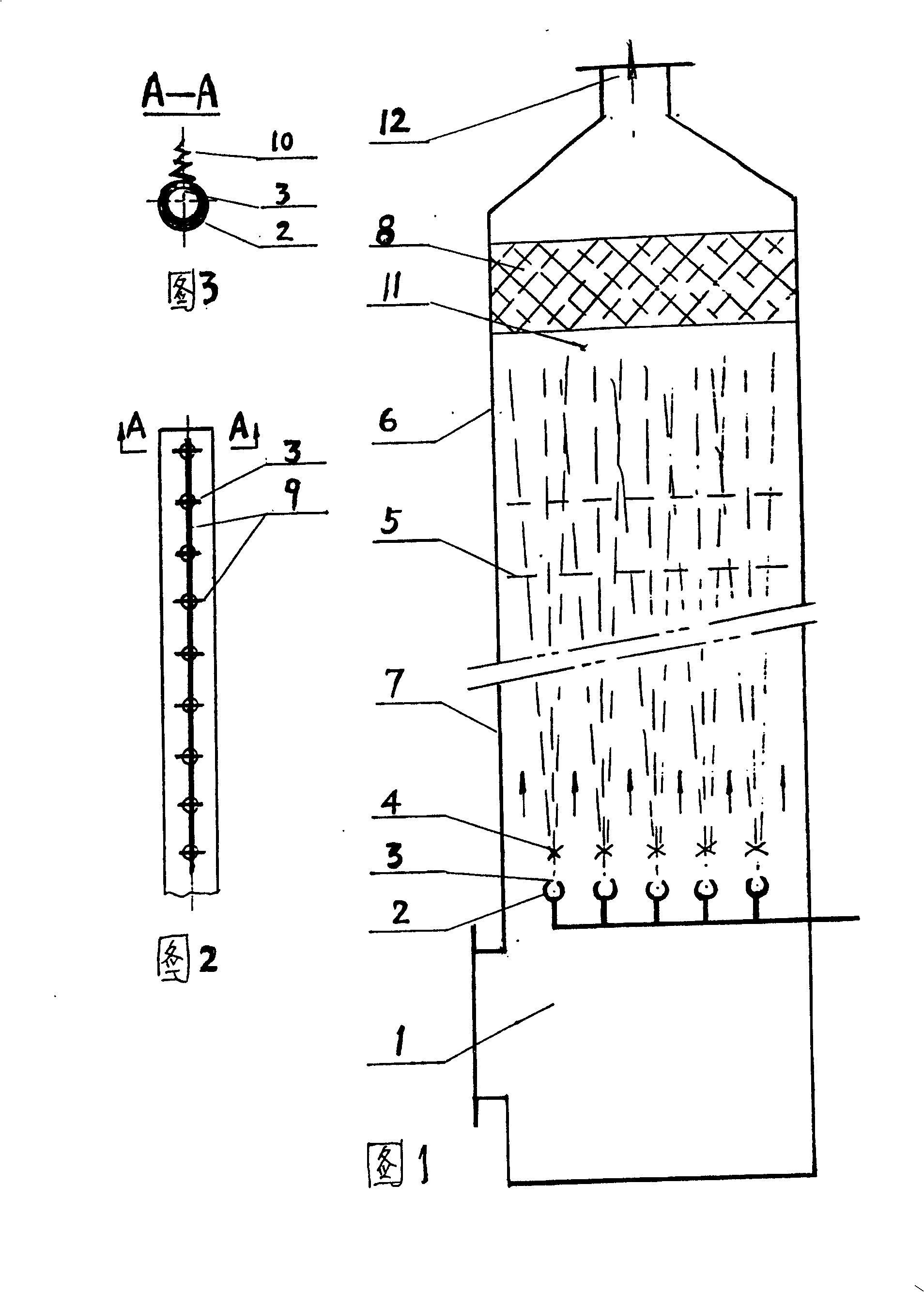

[0009] Below in conjunction with accompanying drawing 1, Fig. 2, Fig. 3, the present invention will be further described in detail.

[0010] In the figure, 1 gas inlet section 2 spray pipe 3 spray hole 4 liquid drop thinning structure 5 screen 6 washing, absorbing and dedusting device 7 washing, absorbing and dedusting section 8 defoaming section 9 thinning steel wire 10 steel wire conical thinning spring 11 The top of the washing, absorbing and dedusting section

[0011] In the upper spraying secondary refinement gas purification technology of the present invention, during operation, the gas enters the gas inlet section 1 and then flows upwards, and passes through the washing, absorption and dust removal section 7 . The lower part of the washing, absorbing and dedusting device is equipped with some evenly arranged spray pipes 2, and the spray pipe 2 is provided with evenly arranged spray holes 3, and the mouths of the spray holes 3 are all upward. The spray hole 3 adopts a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com