Method for treating slag through boiler steaming-water circulation process

A technology of slag treatment and slag, which is applied in the field of process and device for heat recovery and utilization of metallurgical liquid slag treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

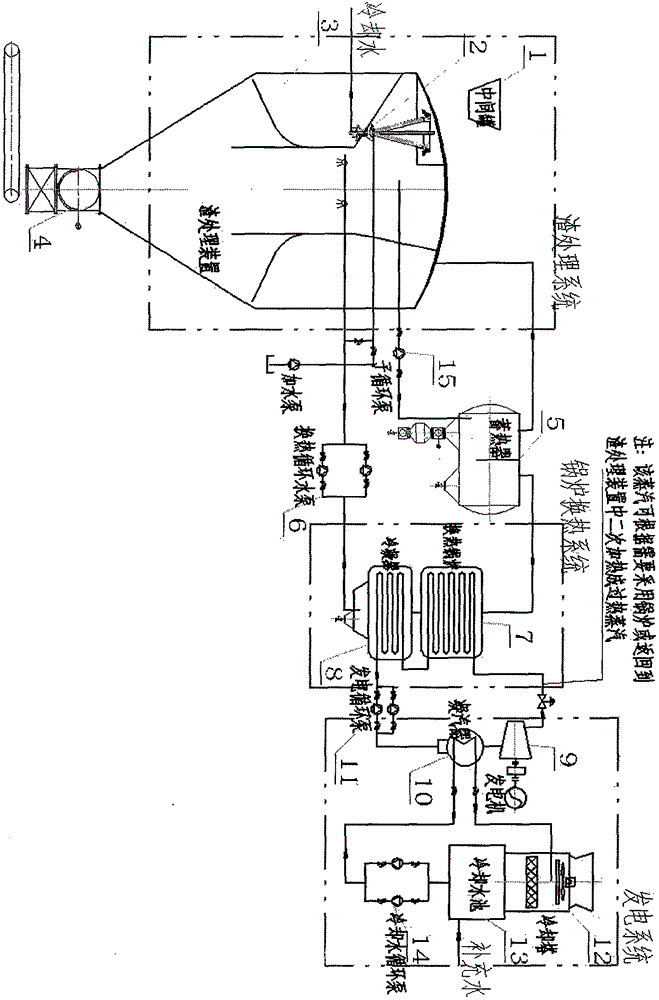

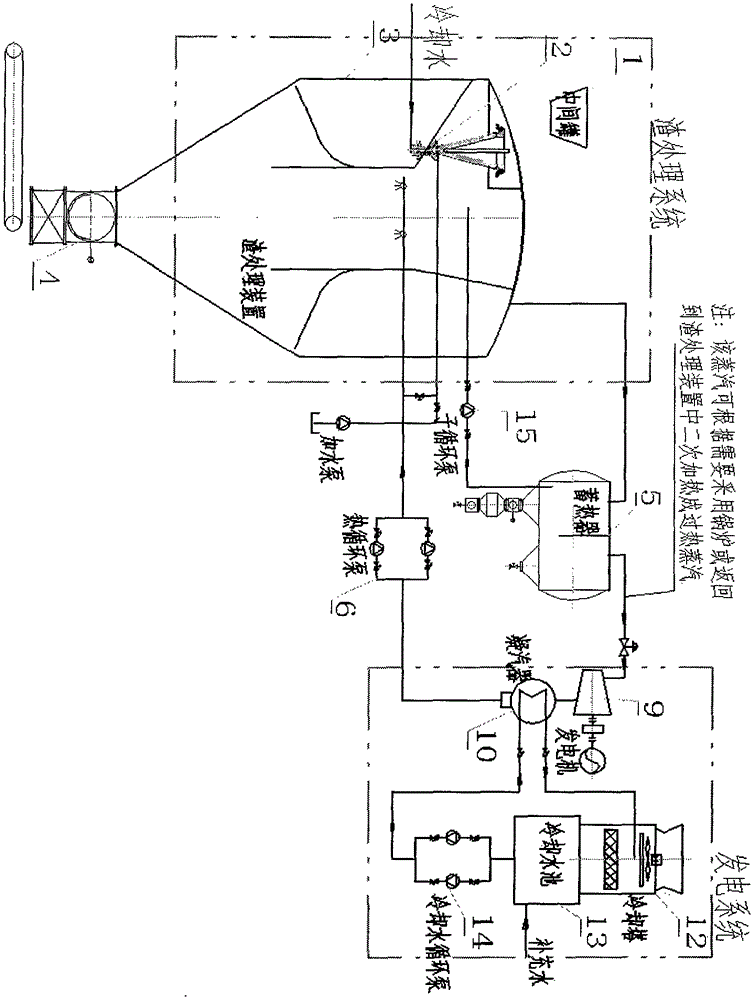

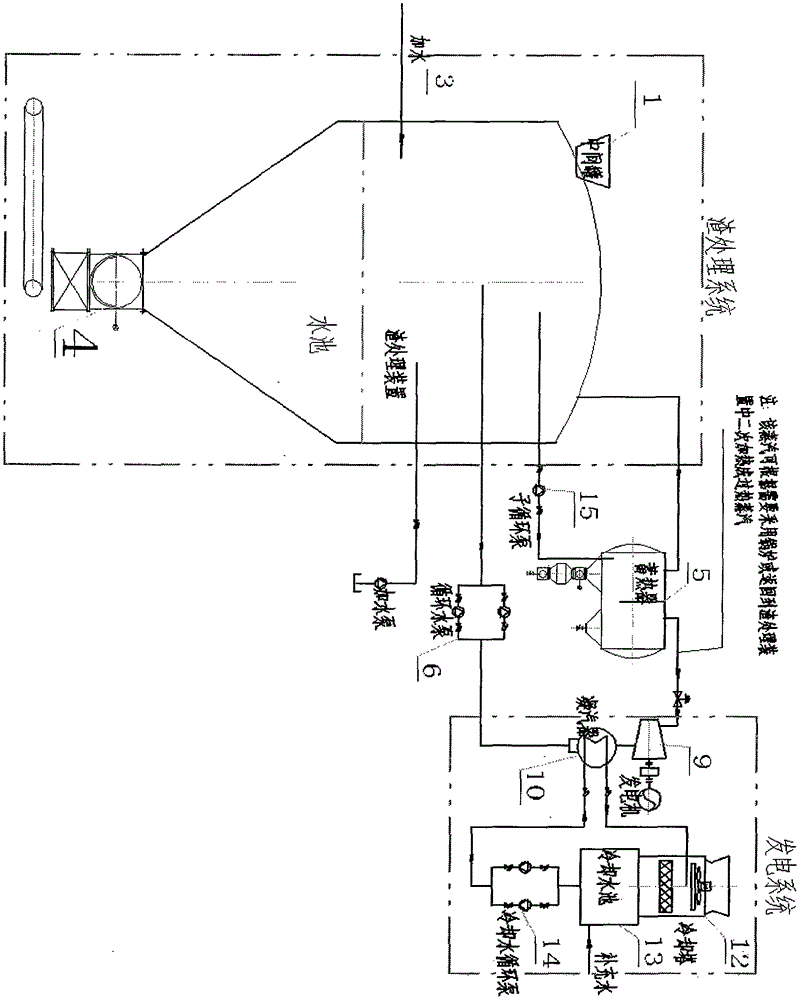

[0045] like figure 1 , figure 2 , image 3 , as shown in Figure 4, the slag treatment process and device of boiler steam-water circulation method are mainly composed of tundish 1, mechanical granulation device 2, slag treatment device 3, heat accumulator 5, heat exchange circulation pump 6, heat exchange boiler 7, condenser 8. Composed of steam turbine 9, condenser 10, power generation circulation pump 11, cooling tower 12, pool 13, cooling water circulation pump 14, sub-circulation pump 15, slag input and output device 4 and automatic control system.

[0046] Process overview:

[0047] Boiler steam-water circulation method slag treatment process mainly includes two contents, one is slag treatment method, that is, slag treatment and slag heat exchange process, which is the core of the project, and the other is steam heat exchange and power generation method, which realizes the method Two closed-circuit cyclic heat transfer processes are adopted, one is the cyclic process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com