Test all-in-one machine for battery module

A battery module and all-in-one technology, which is applied in the direction of measuring electricity, measuring devices, and measuring heat, can solve problems such as time-consuming, test records cannot be automatically saved, and affect the overall efficiency of the power battery module inspection process, so as to meet production requirements. The effect of process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

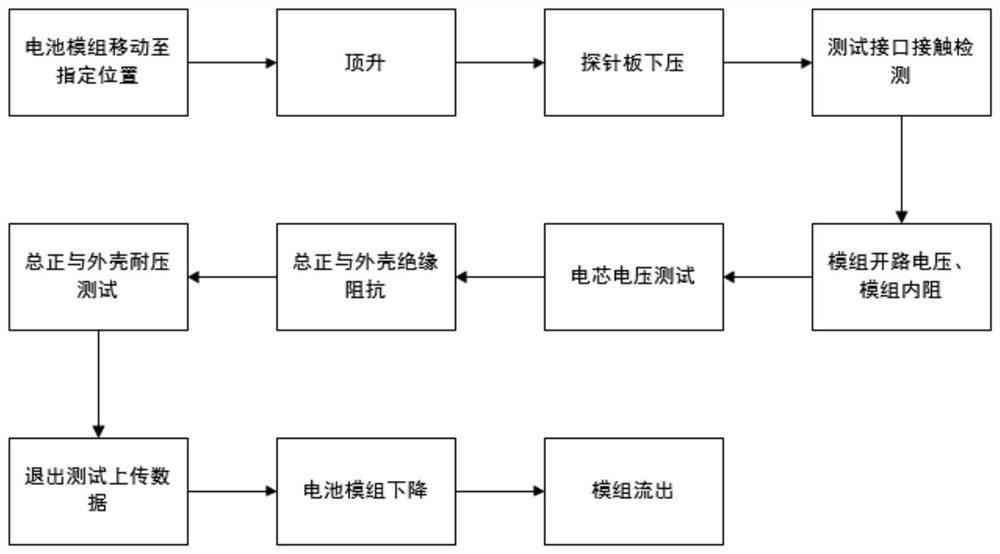

[0021] This embodiment provides a battery module testing all-in-one machine, which is used to realize the open-circuit voltage of the module, wiring harness on-off detection, withstand voltage, and full-automatic testing of insulation. Discriminate, automatically record and save the test data, upload to the MES system, and then realize the matching of the upstream and downstream production capacity of the equipment to meet the production process requirements.

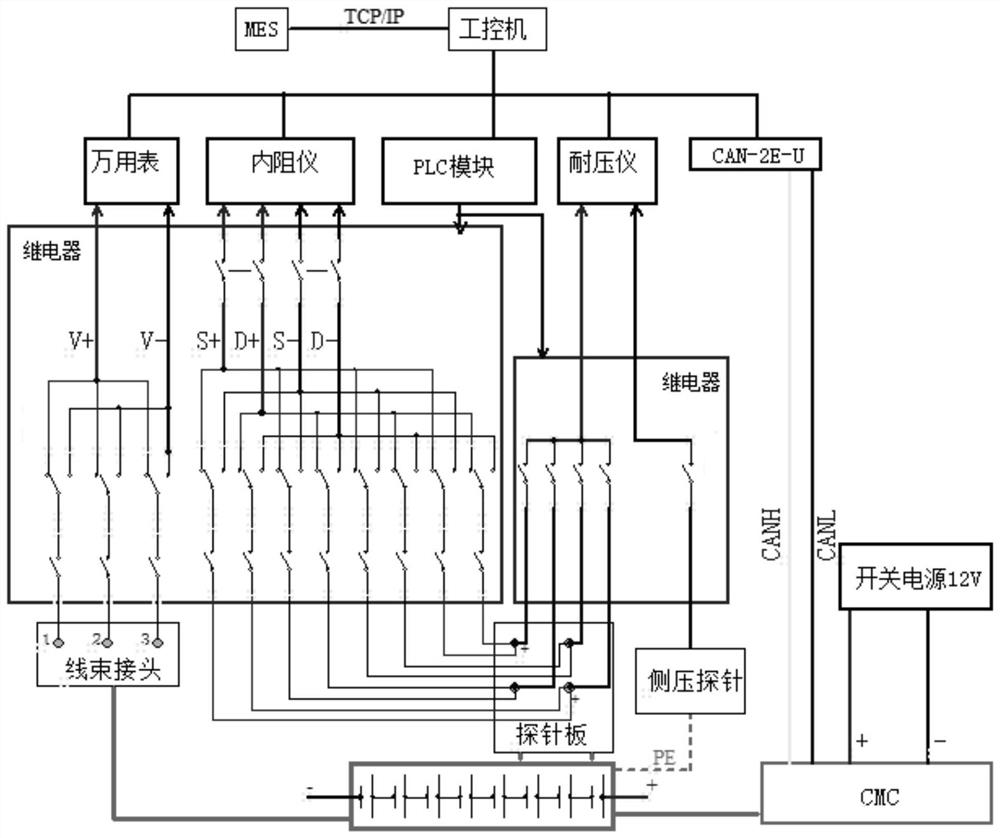

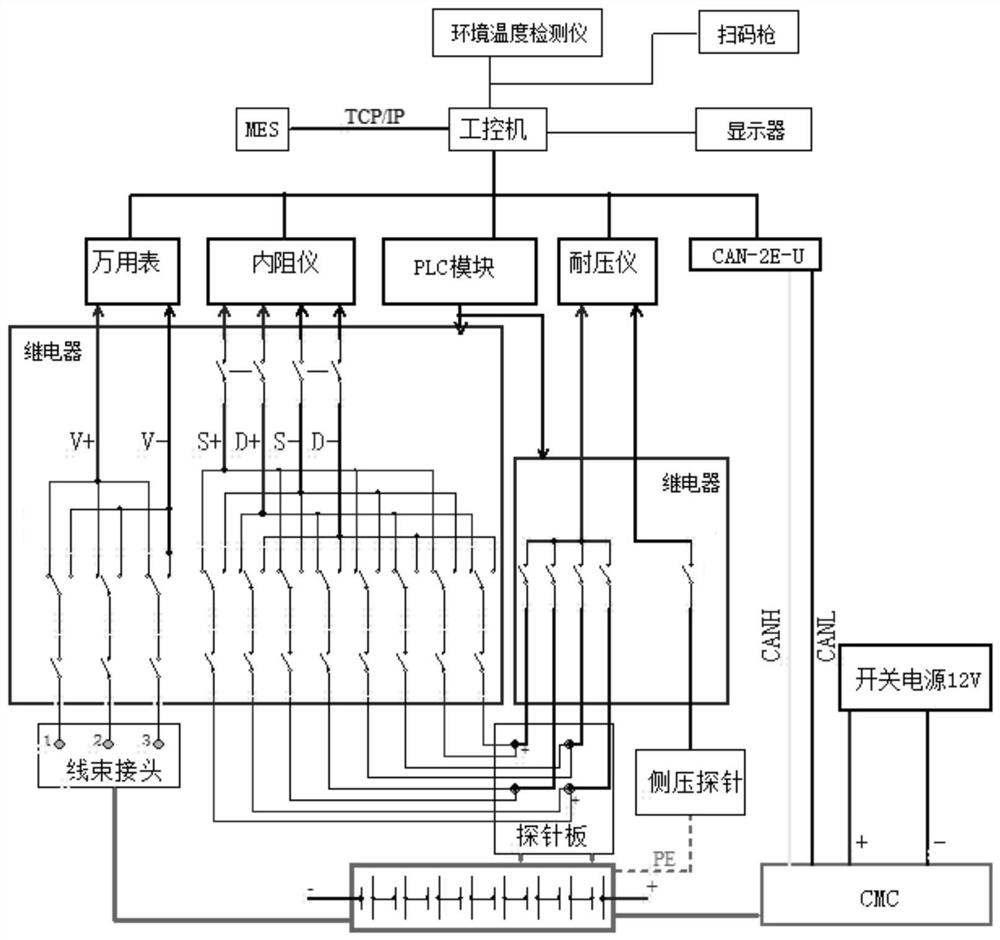

[0022] In this example, if figure 1 , figure 2 As shown, the battery module testing all-in-one machine includes an industrial computer and a multimeter connected to the industrial computer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com