System and method for controlling secondary glue dipping of intestine-dissolvable capsule making machine

A technology of secondary dipping in glue and enteric-coated capsules, which is applied in capsule delivery, pharmaceutical formulation, drug delivery, etc. It can solve the problems that the production process of enteric-coated capsules cannot be satisfied, and achieve the effect of filling the gap and relieving side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

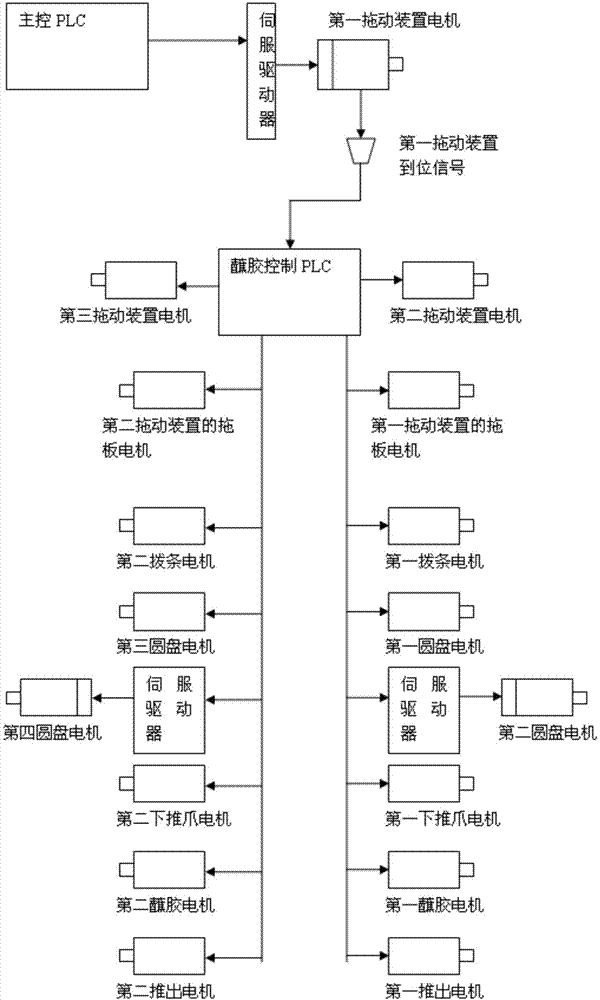

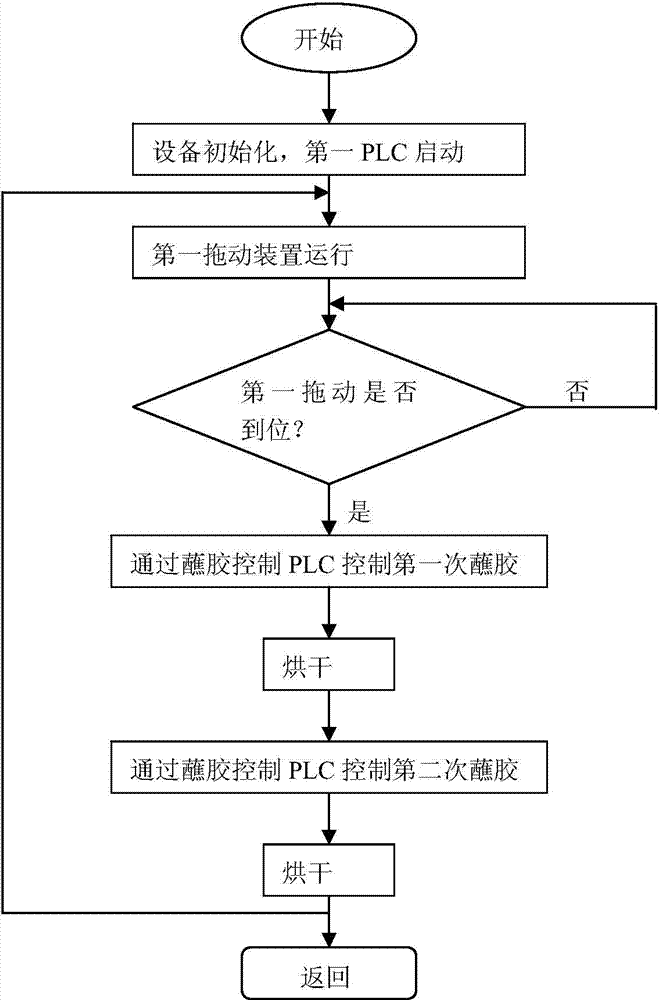

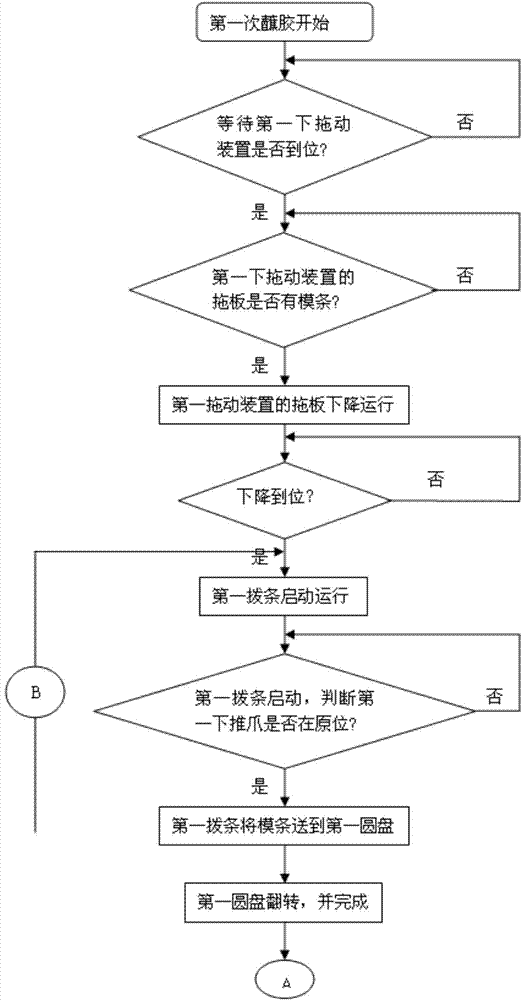

[0059] Such as figure 1 As shown, an enteric-coated capsule machine secondary dipping control system of the present invention has a main control unit, a dipping control unit, first to third dragging devices, first to second dragging device carriages, first to second Handle bar, first to fourth discs, first to second push-down jaws, first to second dipping machine, and first to second ejector, wherein the main control unit controls the rotation of the first driving device motor, and the dipping control unit Receiving the running in-position signal of the first drag device, the glue control unit outputs control instructions to the second to third drag device motors, the first to second drag device carriage motors, the first to second slide motors, and the first to third drag motors. The control circuit of the four-disc motor, the first to second push-do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com