Application of a kind of Lactobacillus casei and its freeze-dried preparation in pig feed

A technology of Lactobacillus casei and freeze-dried preparations, which is applied in the field of microbiology, can solve the problems that are not related to the acid production performance of the bacteria, the inhibition of harmful bacteria, and the survival rate of freeze-dried preparations, so as to achieve strong acid production, improve health status, Acid resistance and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

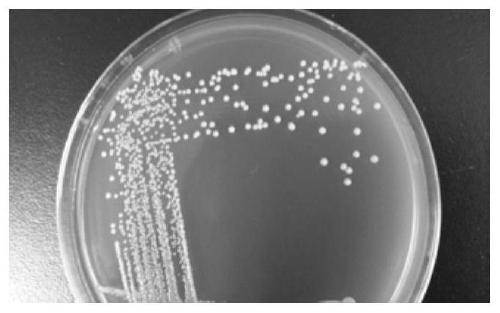

[0029] Example 1 Isolation, screening and identification of pig-derived Lactobacillus casei ZLC018

[0030] Select healthy nursery pigs from a large-scale pig farm in Beijing to slaughter, take the intestines, scrape the intestinal mucosa and mix them with sterile saline. Take 1mL of the suspension and dilute to 10 with sterile normal saline -5 、10 -6 、10 -7 , 0.1 mL each was spread on MRS solid medium, SL solid medium and LBS solid medium, and cultured anaerobically at 37°C. After 48 hours, the milky white colonies suspected of Lactobacillus were picked for anaerobic pure culture. After 48 h, half of the cultured colonies were picked for H 2 o 2 Enzyme test and Gram stain microscopic examination, all Gram stain positive, H 2 o 2 The strains with negative enzyme test and rod-shaped bacteria can be preliminarily identified as Lactobacillus. Then the remaining half of the colonies were streak cultured until they were determined to be pure bacteria, and then the isolated ...

Embodiment 2

[0046] Embodiment 2 measures the biological characteristics of Lactobacillus casei ZLC018

[0047] 2.1 Growth curve

[0048] Using OD 600nm The growth characteristics of Lactobacillus casei ZLC018 were determined using pH and pH as indicators. see results figure 2 Lactobacillus casei ZLC018 culture process OD 600nm Curve, image 3 pH change curve during the culture process of Lactobacillus casei ZLC018.

[0049] Depend on figure 2 , image 3 It can be seen that the OD of Lactobacillus casei ZLC018 during 4-12h 600nm The pH value increased rapidly, and the pH value decreased rapidly; during 12 to 18 hours, the OD of the bacterial solution 600nm and pH changes gradually decreased, indicating that the logarithmic growth phase has been reached; OD after 18h 600nm and pH value did not change significantly, indicating that the bacteria had entered a stable growth period.

[0050] 2.2 Determination of acid production

[0051] The seed liquid of Lactobacillus casei ZLC018...

Embodiment 3

[0075] Embodiment 3 prepares Lactobacillus casei preparation

[0076] The freeze-dried preparation of lactic acid bacteria has the characteristics of stable activity, easy storage and convenient use. Freeze-dried preparations can be directly added to feed, or mixed with drinking water to make liquid preparations with different live bacteria content for animals to drink, and can also be mixed with feed raw materials or complete feed for solid multiplication culture or solid-state fermentation. In the production process of freeze-dried preparations, the formula of culture medium, freeze-drying protective agent and freeze-drying process are important technical links, which directly affect the survival rate of viable bacteria, the number of viable bacteria in freeze-dried preparations, and the unit production cost. The present invention has carried out technological improvement to these three technical links, has obtained remarkable effect.

[0077] 3.1 Improved culture medium fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com