Method for preparing full wheat malt turbid beer wheat juice

A technology for turbid beer and wheat malt, which is applied in the field of preparation of whole wheat malt turbid beer wort, can solve the problems of increasing equipment cost, maintenance cost, occupation of manpower, material resources and financial resources, etc., and achieves the effect of wide-ranging sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Determination of the amount of wheat bran added:

[0027] 1. Wheat germ is crushed, and wheat bran is added to wheat germ, wheat germ:wheat bran=100:0~10 (mass ratio)

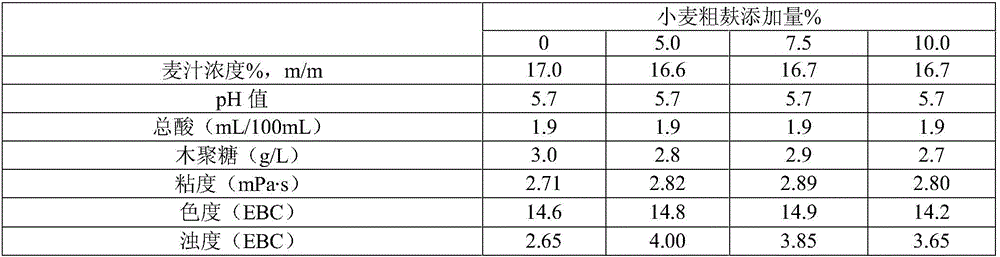

[0028] 2. Mix wheat germ and wheat bran into the mash pot, rest at 45°C for 20 minutes; heat up to 55°C at a speed of 1°C / min and rest for 30 minutes for protein; heat up to 62°C at a speed of 1°C / min and rest for 10 minutes; Raise the temperature at a rate of 1°C / min to 70°C for liquefaction until the iodine reaction disappears, then rapidly raise the temperature to 76-80°C and filter to obtain the first wort. The physical and chemical indicators of the first wort are shown in Table 1. It can be seen from Table 1 that the use of 5% to 10% wheat bran can reduce the viscosity of the first wort and increase the turbidity of the wort without significantly affecting other quality indicators of the wort.

[0029] Table 1 The physical and chemical indicators of the first wort in the wheat bran addition test ...

Embodiment 2

[0032] 1. Raw materials: wheat germ, wheat bran, of which wheat germ:wheat bran (above 20 mesh)=100:7.5 (mass ratio);

[0033] Hops; saccharification material water ratio (wheat malt + wheat bran): water = 1:4 (mass ratio);

[0034] 2. Grind the wheat germ, put it into the mash pot, rest at 45°C for 20 minutes; raise the temperature to 55°C at a speed of 1°C / min and maintain it for 30 minutes to rest for protein; raise the temperature at a speed of 1°C / min to 62.5°C and rest for 10 minutes for saccharification; / min speed up to 70°C for liquefaction until the iodine reaction disappears, then rapidly heat up to 80°C to obtain mash, to be filtered;

[0035] 3. Preheat the filter tank with 80°C water, put the coarse wheat bran into the filter tank to soak for 30 minutes, wash, remove the gas at the bottom of the tank and excess preheated water to remove the soluble substances remaining in the coarse wheat bran. Pump all the mash produced in step 2) to the lauter tank, let stand,...

Embodiment 3

[0039] 1. Raw materials: wheat germ, wheat bran, of which wheat germ:wheat bran (above 20 mesh)=100:7.5 (mass ratio);

[0040] The water ratio of saccharification material is (wheat malt + wheat bran): water = 1:4 (mass ratio); hops;

[0041] 2. Grind the wheat germ and put it into the saccharification pot together with the coarse wheat bran screened over 20 meshes, rest at 40-45°C for 30 minutes; raise the temperature to 55°C at a speed of 1°C / min and maintain it for 40 minutes for protein resting; at 1°C / min Raise the temperature to 63°C for saccharification for 10 minutes; then raise the temperature to 70°C at a speed of 1°C / min for liquefaction until the iodine reaction disappears, and rapidly raise the temperature to 80°C to obtain mash, which is to be filtered;

[0042] 3. Preheat the lauter tank at 80°C, remove the gas at the bottom of the tank, put the mash prepared in step 2 into the preheated lauter tank, let it stand, filter, wash the bad, and obtain the filtered wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com