Europium-terbium co-doped luminescent material and preparation method and application thereof

A luminescent material, europium terbium technology, applied in luminescent materials, material analysis through optical means, analysis of materials, etc., can solve the problem of poor anti-interference ability of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a preparation method of europium and terbium co-doped luminescent material, comprising the following steps:

[0055] A) After mixing and reacting adenine, 4,4'-biphenyldicarboxylic acid, zinc acetate dihydrate, a strong acid and a solvent, an intermediate product is obtained;

[0056] B) After mixing the intermediate product obtained in the above steps with the terbium source and europium source solution again and standing still, the europium and terbium co-doped luminescent material is obtained.

[0057] In the invention, adenine, 4,4'-biphenyldicarboxylic acid, zinc acetate dihydrate, strong acid and solvent are mixed and reacted to obtain an intermediate product.

[0058] The present invention has no special restrictions on the strong acid, and the strong acid well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual application conditions, raw material conditions and product requirem...

Embodiment 1

[0080] step one:

[0081] Adenine (0.25mmol), 4,4-biphenyldicarboxylic acid (0.5mmol) and zinc acetate dihydrate (0.75mmol) were dissolved in a mixture of DMF (27mL) and water (2mL), stirred for 60 minutes, Nitric acid (2 mmol) was then added. The above solution was transferred to a 40 mL reaction kettle and heated at 130° C. for 48 hours. After cooling to room temperature, the needle-shaped crystals were obtained by suction filtration. The crystals were washed several times with DMF and dichloromethane, and vacuum-dried at 120° C. overnight to obtain sample 1.

[0082] Step two:

[0083] The sample 1 prepared in step 1 was added to a saturated DMF solution with a molar ratio of terbium and europium of 3:1, and left overnight. Suction filtration and drying overnight at 120° C. to obtain a europium and terbium co-doped luminescent porous material.

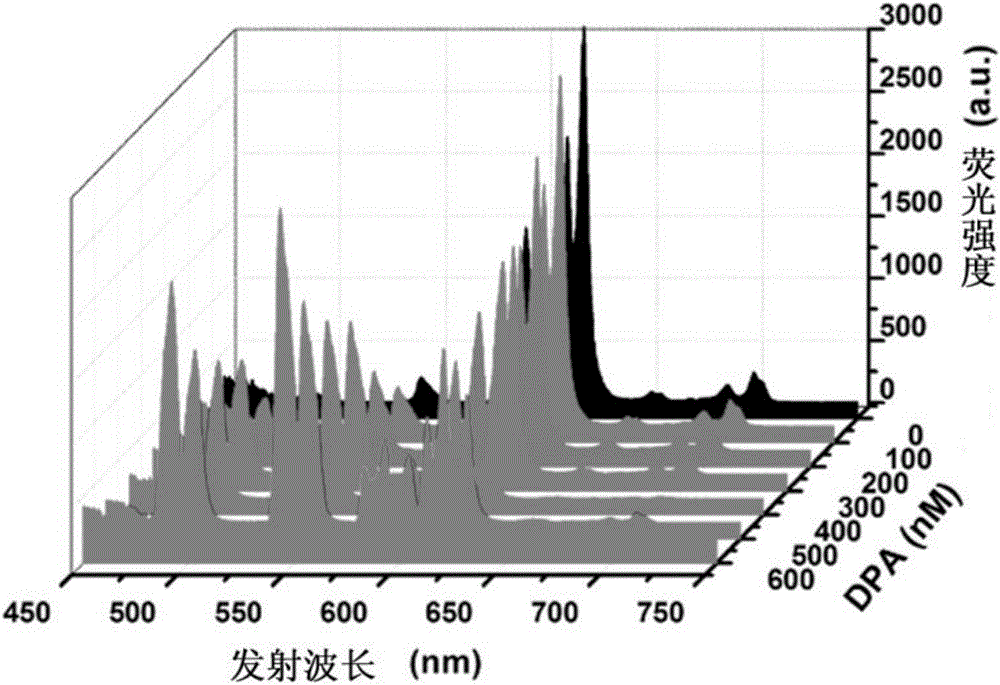

[0084] Detection is carried out on the europium and terbium co-doped luminescent porous material prepared in the above steps o...

Embodiment 2

[0087] Step 1: with embodiment 1;

[0088] Step two:

[0089] The sample 1 prepared in step 1 was added to a saturated DMF solution with a molar ratio of terbium and europium of 6:1, and left overnight. Suction filtration and drying overnight at 120° C. to obtain a europium and terbium co-doped luminescent porous material.

[0090] Detection is carried out on the europium and terbium co-doped luminescent porous material prepared in the above steps of the present invention.

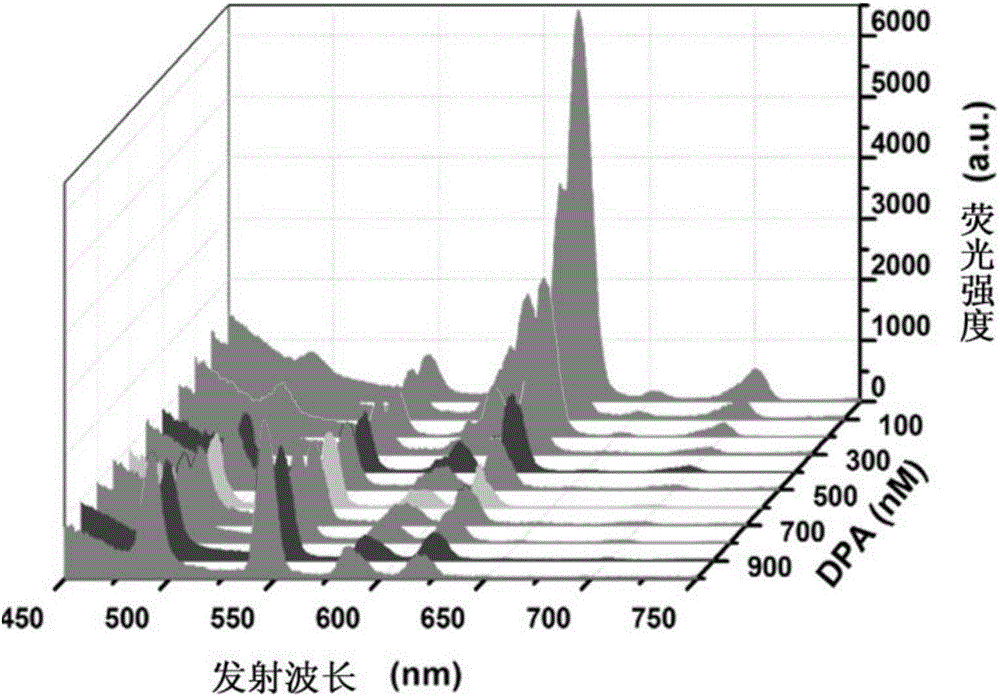

[0091] see figure 2 , figure 2 Fluorescent response diagrams of the europium-terbium co-doped luminescent porous material prepared for Example 2 of the present invention with a terbium-europium molar ratio of 6:1 to different concentrations of DPA. It can be seen from the figure that the co-doped material in Example 2 has a ratiometric fluorescence response to DPA, the luminescence of europium gradually weakens and the luminescence of terbium gradually increases, and the detection limit of DPA is 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com