Method and device for improving wastewater treatment biological film forming efficiency

A wastewater treatment and biofilm technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of limited applicability, high cost, and low efficiency of film formation. Achieve the effects of reducing time and difficulty of operation, low cost, and high efficiency of film hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Since my country needs to upgrade the water quality of water plants, a large number of water plants are facing the problem of upgrading and transformation. The biofilm method provides new ideas for the upgrading and transformation of water plants, but in some water bodies it is difficult to form biofilm on the surface of the filler, and it is necessary to develop methods and devices to promote film formation for special water bodies.

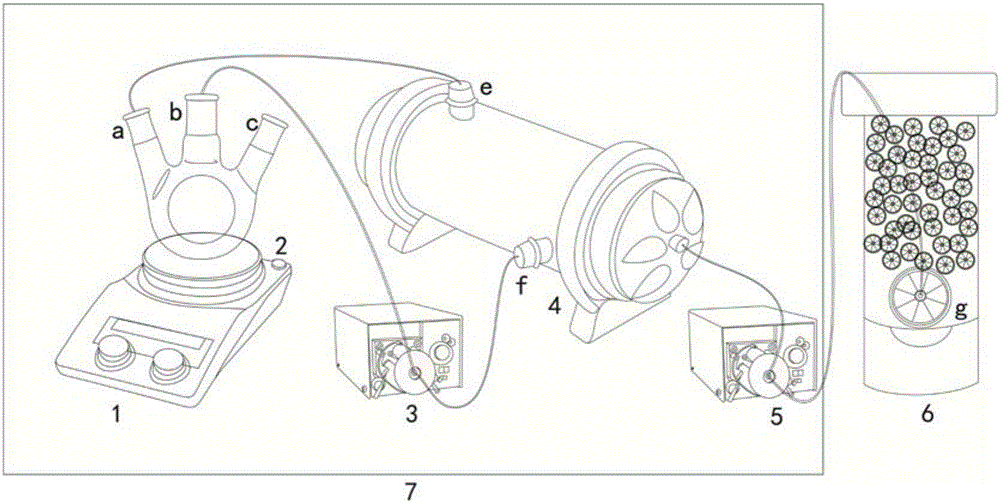

[0050] Such as figure 1 As shown, a device for improving the efficiency of biofilm formation in wastewater treatment includes a magnetic stirrer 1, and a three-mouth flask 2 is arranged on the magnetic stirrer 1. One mouth of the three-mouth flask 2 is a bacterial liquid feeding port b, and the other mouth is a bacterial liquid feeding port b. The liquid return port a, one port is the bacterial liquid supply port c, the bacterial liquid feeding port b passes through the first peristaltic pump 3 pipeline and the bacterial liquid is added t...

Embodiment 2

[0053] A method for improving the efficiency of biofilm formation in wastewater treatment, comprising the following steps:

[0054] (1) Sampling the membrane-hanging mud-water mixture, centrifuging and dehydrating in a high-speed rotary centrifuge, removing the supernatant, and taking mud samples; the speed of the high-speed centrifuge is 12000×g~14000×g; the centrifugation time is 10~20min;

[0055] (2) Add ethyl acetate to the mud sample to extract homoserine lipids; (C4-C14-HSL) the extraction method is ultrasonic extraction, the extraction conditions are: ultrasonic power 150-200w, extraction time 60-90min, extraction The temperature is 25-30°C, the volume of the extraction solution is 10-30mL, and the extraction is 3-5 times;

[0056] (3) Sampling high-performance liquid chromatography-mass spectrometry to detect the content of homoserine lactones; liquid phase-mass spectrometry equipment, select triple quadrupole equipment, and the measurement conditions are: chromatogra...

Embodiment 3

[0072] The effluent quality of an industrial wastewater cannot meet the requirements of Class I (A), and the biofilm method is proposed to upgrade the original aerobic pool.

[0073] The specific implementation process of this example is:

[0074] 1. Sampling the membrane-hanging mud-water mixture in a high-speed rotary centrifuge at 12000×g; the centrifugation time is 10 minutes, discard the supernatant, and take mud samples;

[0075] 2. Add ethyl acetate to extract homoserine lipids, here is C4-HCL, ultrasonic power 150w, extraction time 60min, extraction temperature 30°C;

[0076] 3. The content of homoserine lactones was detected by sampling high-performance liquid chromatography-mass spectrometry; the determination conditions were: chromatographic conditions: flow rate: 0.2mL / min; injection volume: 10μL; analysis time: 12min; column temperature : 35 DEG C; Mobile phase A is methyl alcohol, contains molar number and is 2mmol / L ammonium acetate and mass number 0.1% formic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com