Catalyst for purifying formaldehyde at room temperature and preparation method thereof

A formaldehyde purification and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of less catalyst recycling and regeneration, and achieve high formaldehyde elimination. Efficiency, efficient recovery, low precious metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use a pipette gun to accurately measure 660 μl of chloroplatinic acid aqueous solution with a concentration of 40 mg / ml (concentration based on the mass of platinum element, the same below) and drop it into a round-bottomed flask filled with 10 ml of deionized water, and ultrasonically disperse it for 20 Minutes; Add 2.57 g of ferrous chloride, and mix evenly under mechanical stirring. Heat the water bath to 90 ºC, add 100 ml of 6.4 mol / L sodium hydroxide aqueous solution, and react for 12 h. The precipitate was magnetically separated, washed several times with deionized water, and dried in a vacuum oven at 90 ºC for 10 h. After being ground in an agate mortar, it becomes a supported catalyst. The loading amount of platinum element in the prepared catalyst was 1% by mass.

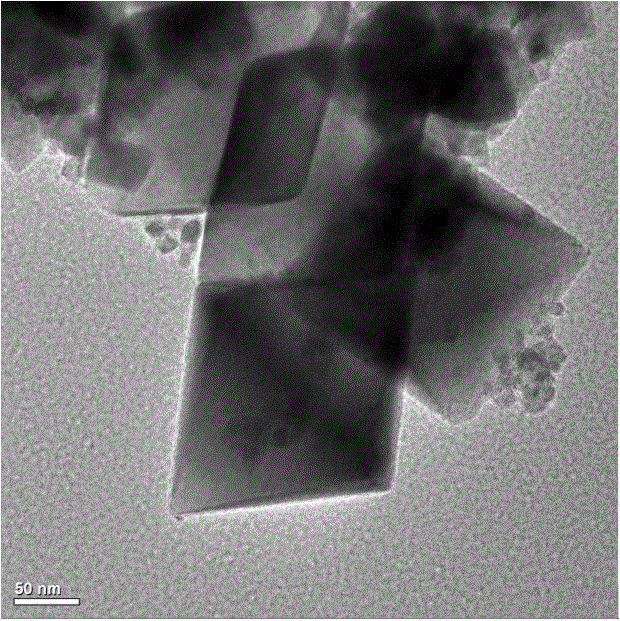

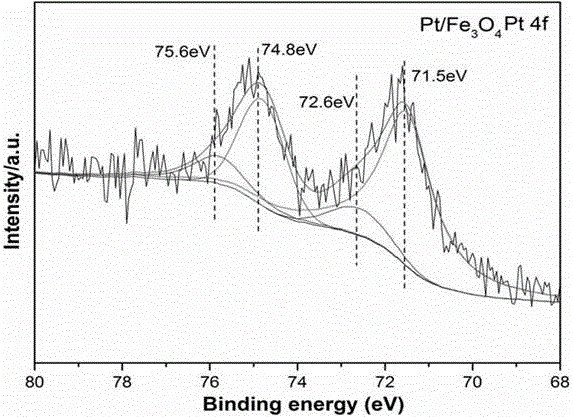

[0021] The catalyst prepared in this example was characterized and detected. figure 1 For the TEM image of the supported catalyst prepared in this example, it can be seen that the platinum nanopar...

Embodiment 2

[0024] Use a pipette gun to accurately measure 330 μl of chloroplatinic acid aqueous solution with a concentration of 40 mg / ml (concentration based on the mass of platinum element, the same below) and drop it into a round-bottomed flask filled with 10 ml of deionized water, and ultrasonically disperse it for 20 Minutes; Add 2.57 g of ferrous chloride, and mix evenly under mechanical stirring. Heat the water bath to 90 ºC, add 100 ml of 6.4 mol / L sodium hydroxide aqueous solution, and react for 12 h. The precipitate was magnetically separated, washed several times with deionized water, and dried in a vacuum oven at 90 ºC for 10 h. After being ground in an agate mortar, it becomes a supported catalyst. The loading amount of platinum element in the prepared catalyst was 0.5% by mass. Using the same method as in Example 1, the characterization test and performance evaluation of the supported catalyst prepared in this example were carried out. The prepared supported catalyst can ...

Embodiment 3

[0026] Use a pipette gun to accurately measure 1000 μl of chloroplatinic acid aqueous solution with a concentration of 40 mg / ml (concentration based on the mass of platinum element, the same below) into a round-bottomed flask filled with 10 ml of deionized water, and ultrasonically disperse for 20 Minutes; Add 2.57 g of ferrous chloride, and mix evenly under mechanical stirring. Heat the water bath to 90 ºC, add 100 ml of 6.4 mol / L sodium hydroxide aqueous solution, and react for 12 h. The precipitate was magnetically separated, washed several times with deionized water, and dried in a vacuum oven at 90 ºC for 10 h. After being ground in an agate mortar, it becomes a supported catalyst. The loading amount of platinum element in the prepared catalyst was 1.5% by mass. Using the same method as in Example 1, the characterization test and performance evaluation of the supported catalyst prepared in this example were carried out. The prepared supported catalyst has excellent cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com