Injectable cosmetic and plastic material and preparation method thereof

A technology for injection and water for injection, applied in the field of materials, can solve the problems of tissue induration and insufficient mechanical strength, and achieve the effect of soft tissue, eliminating wrinkles and depressions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

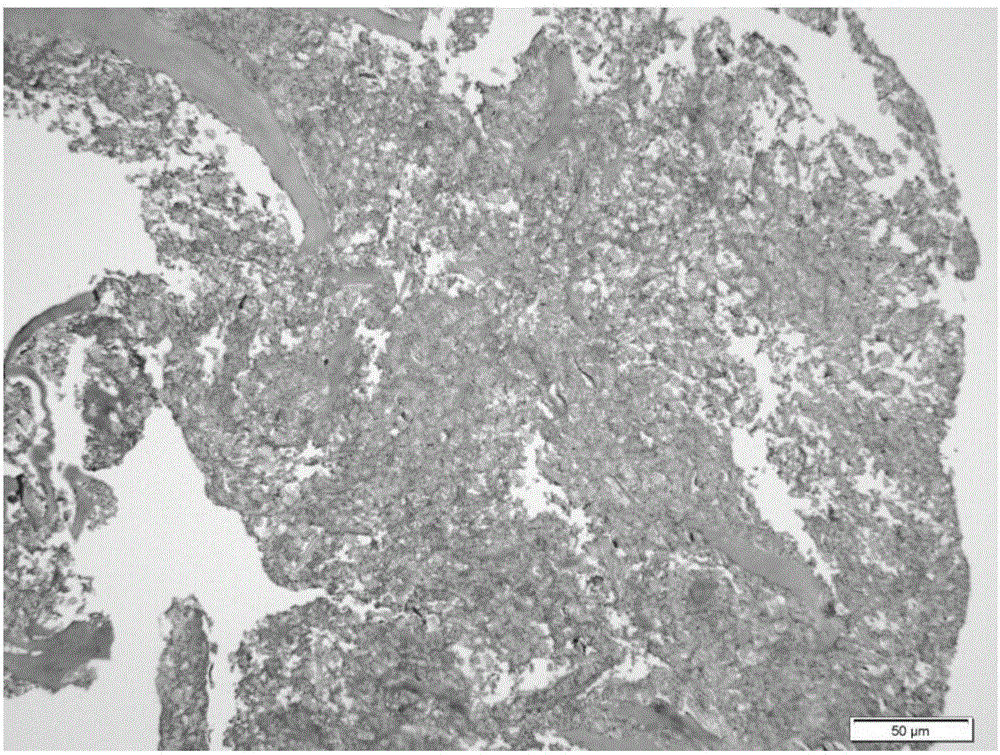

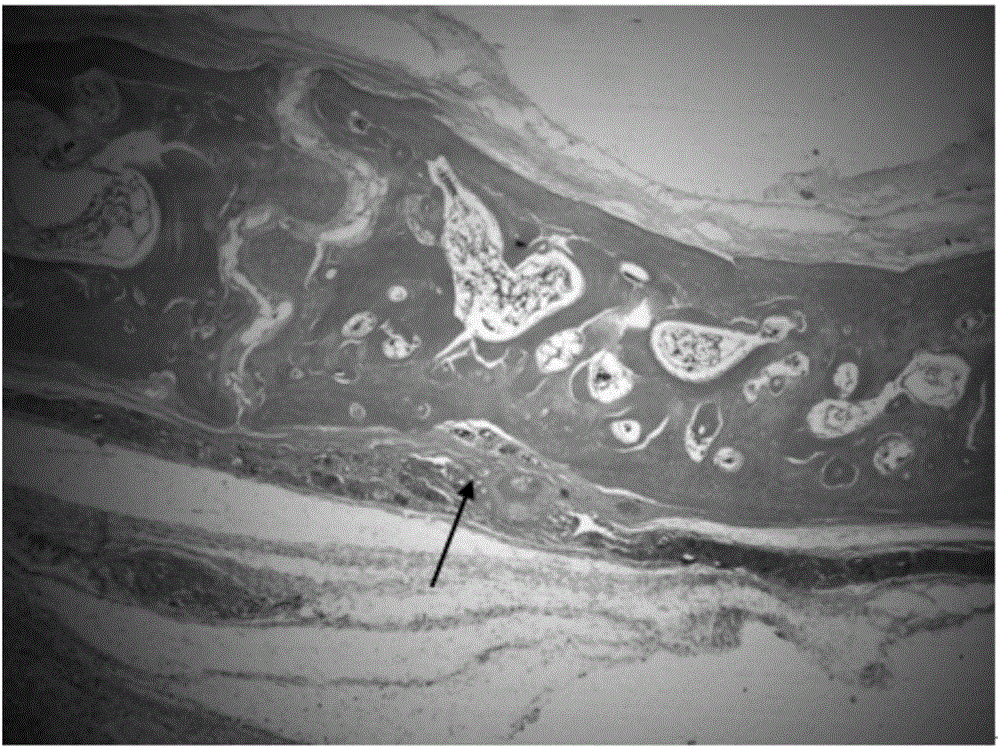

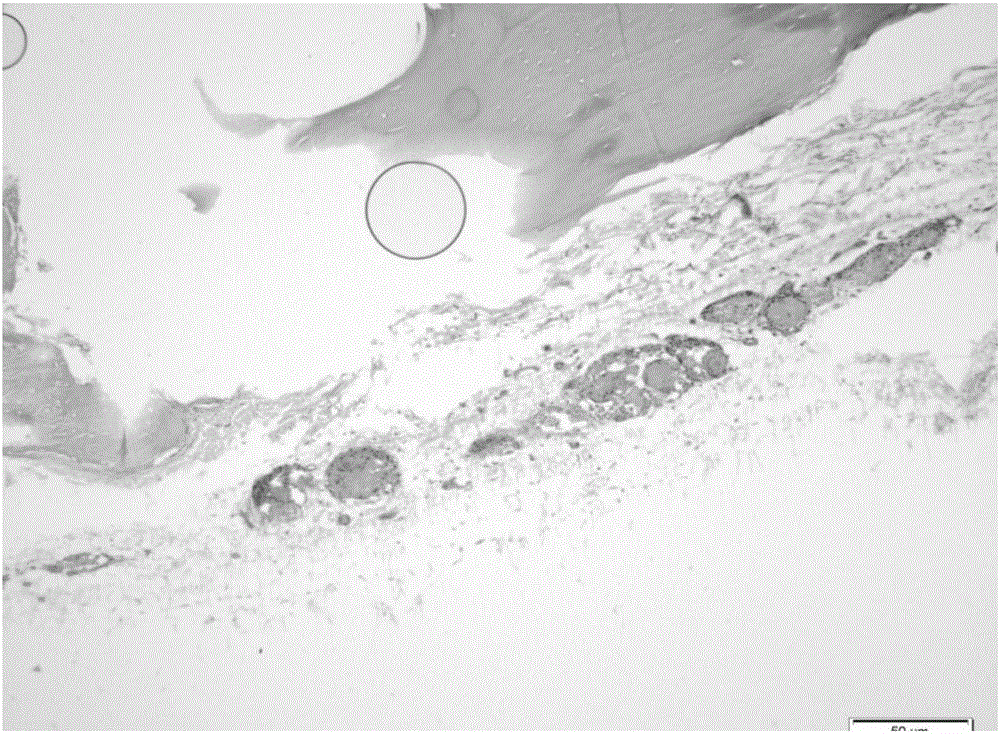

Image

Examples

Embodiment 1

[0066] The collagen sponge was pulverized into powder with a pulverizer, the speed of the pulverizer was set at 7000rpm, and the time was set at 2s to obtain collagen powder.

[0067] The used spherical hydroxyapatite powder with a particle size of 30 μm and the collagen powder prepared in the above steps are sterilized by cobalt 60 radiation to ensure the sterility of the raw materials.

[0068] Disassemble some parts of the reaction kettle that are in contact with the product, wrap them separately with the scissors, tweezers, wrench, etc. used for preparation, and affix them with moist heat sterilization instructions, put them in a steam sterilizer, and sterilize with moist heat at 120°C for 30 minutes.

[0069] Add 40g of sterilized collagen powder in 4 times and 1000mL of sterile water for injection alternately into the reactor until the addition is complete, seal the reactor, start stirring at a speed of 120r / min, stir and react for 24 hours, and start at the same time Ul...

Embodiment 2

[0072] The collagen sponge was pulverized into powder with a pulverizer, the rotating speed of the pulverizer was set at 8000rpm, and the time was set at 2s to obtain collagen powder.

[0073] The used spherical hydroxyapatite powder with a particle size of 35 μm and the collagen powder prepared in the above steps were sterilized by cobalt 60 radiation to ensure the sterility of the raw materials.

[0074] Disassemble some parts of the reaction kettle that are in contact with the product, wrap them separately with the scissors, tweezers, wrench, etc. used for preparation, and affix them with moist heat sterilization instructions, put them in a steam sterilizer, and sterilize with moist heat at 120°C for 30 minutes.

[0075] Add 50g of sterilized collagen powder and 950mL of sterilized water for injection into the reaction kettle alternately in batches until the addition is complete, seal the reaction kettle, start stirring at a speed of 120r / min, stir and react for 24 hours, an...

Embodiment 3

[0078] The collagen sponge is pulverized into powder with a pulverizer, the rotating speed of the pulverizer is set at 12000rpm, and the time is set at 1s to obtain collagen powder.

[0079] The used spherical hydroxyapatite powder with a particle size of 40 μm and the collagen powder prepared in the above steps were sterilized by cobalt 60 radiation to ensure the sterility of the raw materials.

[0080] Disassemble some parts of the reaction kettle that are in contact with the product, wrap them separately with the scissors, tweezers, wrench, etc. used for preparation, and affix them with moist heat sterilization instructions, put them in a steam sterilizer, and sterilize with moist heat at 120°C for 30 minutes.

[0081] Add 50ml of lidocaine into 950ml of sterilized water for injection to form a first solution. Add 40g of sterilized collagen powder and the first solution alternately to the reactor until the addition is complete, seal the reactor, start stirring at a speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com