Compound spraying agent and application thereof in promotion of crop kernel filling and seed viability

A technology for spraying agents and crops, which is applied in the field of crop production to achieve the effects of improving seed vigor, preventing phytotoxicity, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of composite spraying agent

[0030] Preparation of component A: mix 2.24g methyl jasmonate with 5ml ethanol, fully dissolve to obtain methyl jasmonate mother liquor; add 5ml methyl jasmonate mother liquor and 2.76g spermidine to 995ml water, fully stir to dissolve , to obtain component A.

[0031] Preparation of component B: Air-dry young ears of sweet corn, grind them to obtain a powder of 0.10-0.15mm (particle size), take 200g of powder and place it in 4L of water at room temperature for 3 days, filter out the insoluble matter, and obtain the composition Point B.

[0032] Mix component A and component B at a ratio of 1:20 (v / v) to obtain a composite spraying agent.

[0033] 2. Spraying of compound spraying agent

[0034] 1. Test materials: sweet corn inbred lines T49-2-6-1-1(♀) and S29-6-2-3(♂)

[0035] 2. Test agent: composite spraying agent

[0036] 3. Test method

[0037] Before the ear of the female parent is silked, bagging is carried out, a...

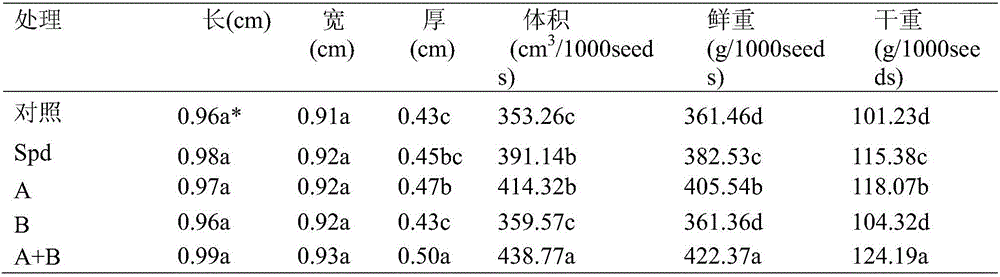

Embodiment 2

[0047] 1. Preparation of composite spraying agent

[0048] The 4 groups of spraying agent treatments and 1 group of control treatments designed in this embodiment are the same as in Example 1.

[0049] 2. Spraying of compound spraying agent

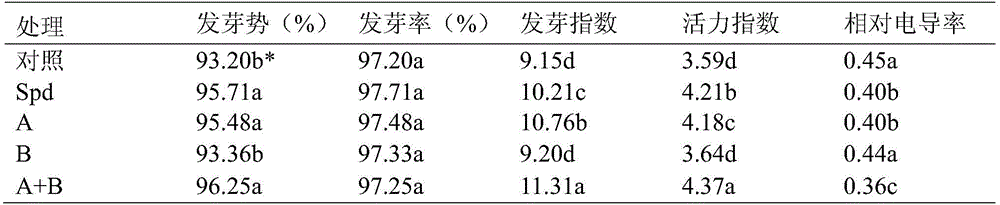

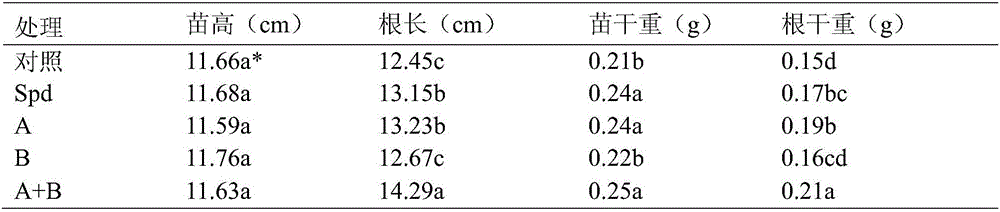

[0050] 1. Test material: F1 seeds of sweet corn inbred lines T49-2-6-1-1(♀) and S29-6-2-3(♂) hybrid.

[0051] 2. Test method

[0052] Seed Germination Test: Germination tests were performed on seeds harvested 26 days after pollination. Refer to the ISTA inspection regulations, use 6×12cm wet paper rolls to germinate, and repeat 4 times, with 100 seeds per repetition. The seeds were placed in a constant temperature incubator at 25°C, and the light setting was 12h light / 12h dark. With the germination standard of radicle breaking through the seed coat by 1 mm, the number of germinations was recorded every day, and the germination potential and germination rate were calculated on the 4th and 7th days of germination, respectively.

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com