Hollow metal nanoparticle, catalyst including same, and method for manufacturing hollow metal nanoparticle

A technology of metal nanoparticles and metal ions, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the environmental pollution of organic solvents, high cost, and difficulty in synthesizing nano Particles and other problems, to achieve the effect of simple process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

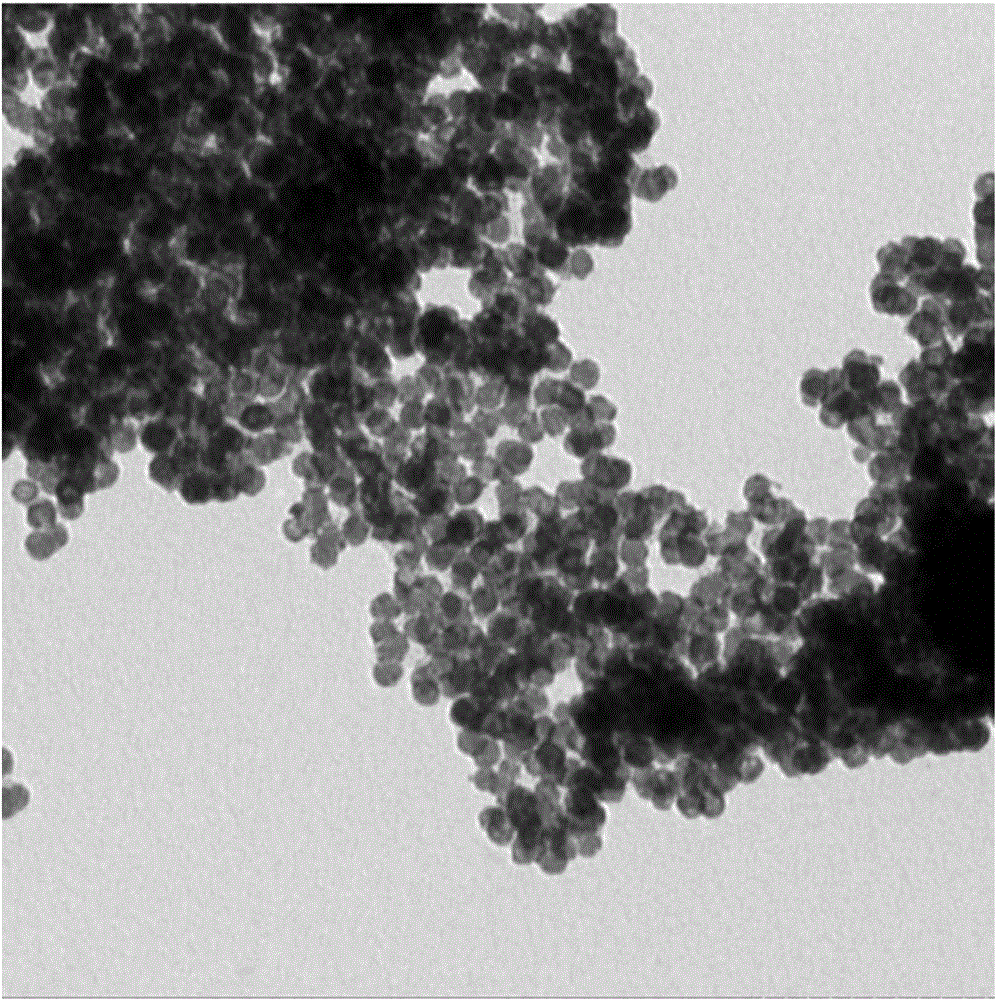

[0072] The method of preparing metal nanoparticles according to one embodiment of the present specification does not utilize a reduction potential difference, and thus has an advantage of not needing to consider a reduction potential between a first metal ion and a second metal ion forming a shell. The preparation method of the present specification utilizes the electric charges in metal ions, and therefore is simpler than the existing method of preparing metal nanoparticles by using a reduction potential difference. Therefore, the method for producing metal nanoparticles of the present specification is advantageous for large-scale production, and can produce metal nanoparticles at low cost. In addition, the method does not utilize a reduction potential difference, and thus has an advantage that a variety of metal salts can be used due to less restrictions on metal salts used compared to existing methods for producing metal nanoparticles.

[0073] This specification provides h...

Embodiment 1

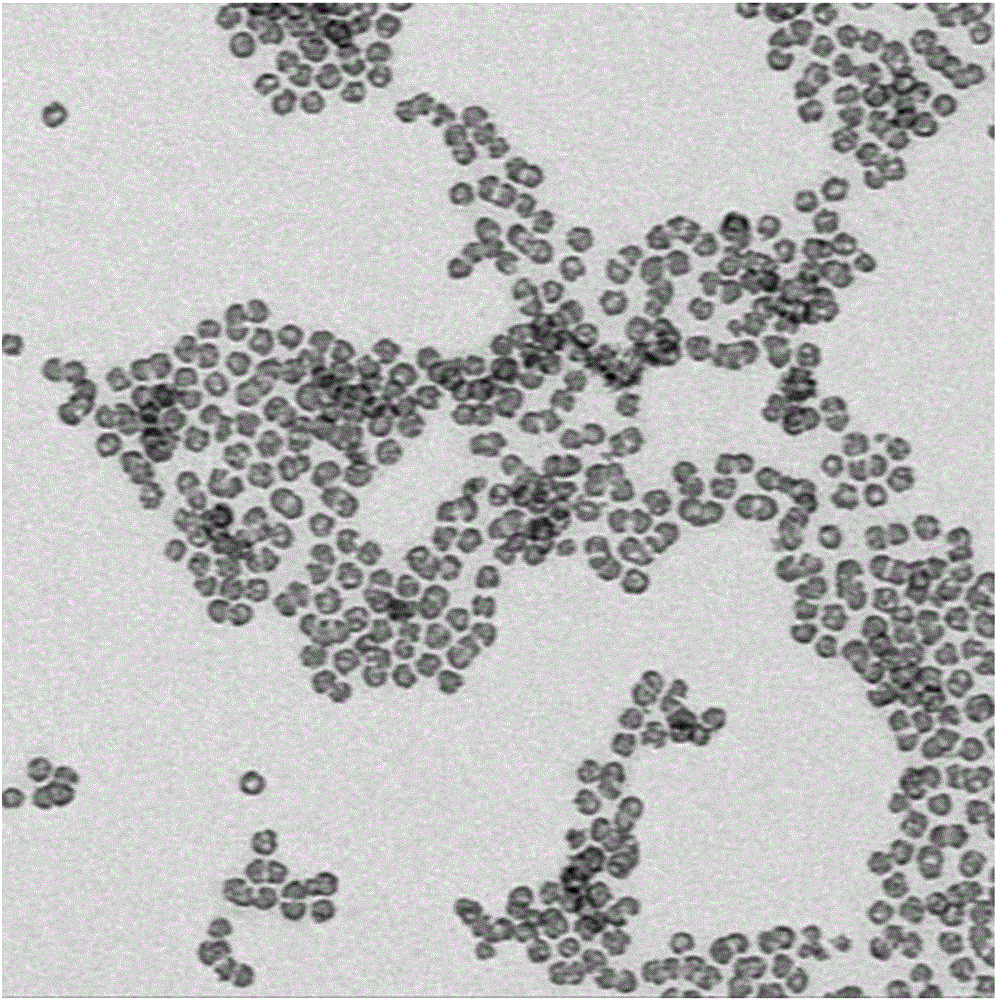

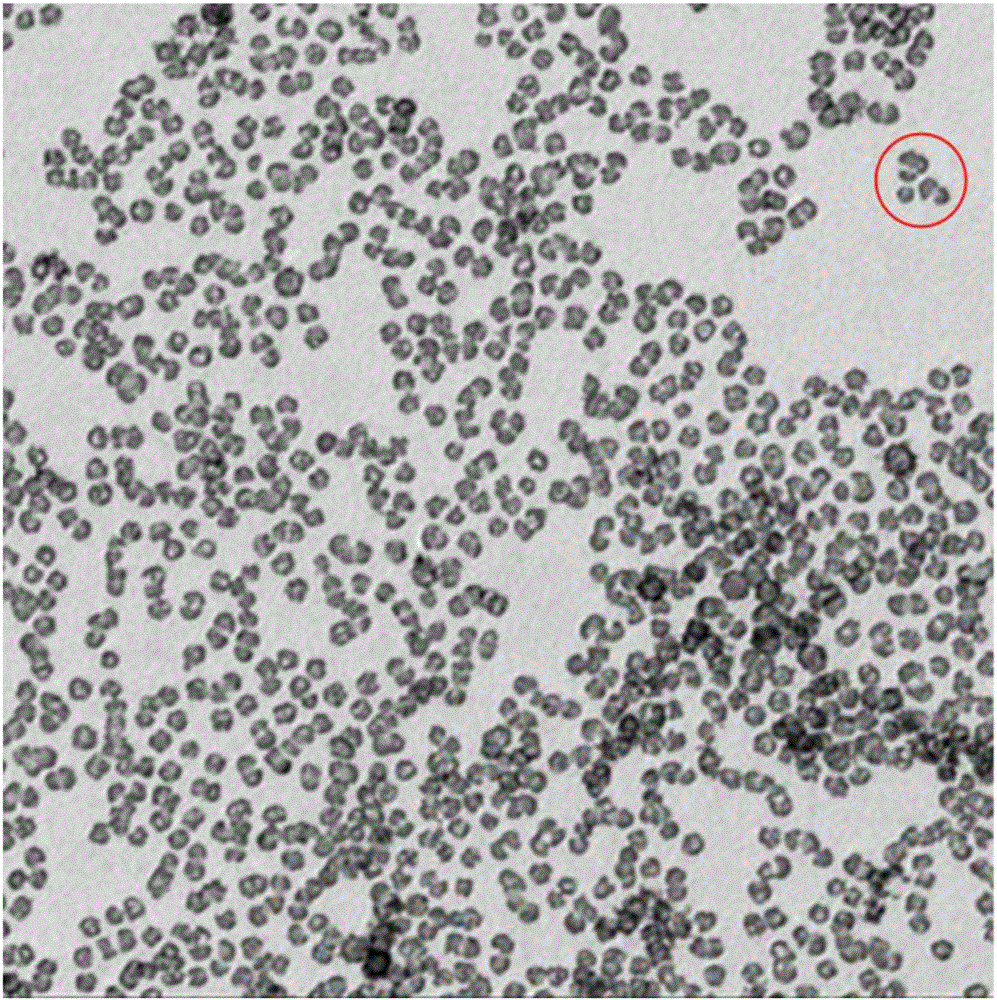

[0108] Ni(NO 3 ) 2 、K 2 PtCl 4 , trisodium citrate, and ammonium lauryl sulfate (ALS) were dissolved in water, and the resultant was stirred for 30 minutes. Here, the molar ratio of Ni precursor to Pt precursor is 3:1, and the ALS is twice the critical micelle concentration (CMC). After stirring for 30 minutes, the reducing agent NaBH was added thereto 4 , and allow the resultant to react for more than 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com